Automatic sterilizer for films

An automatic disinfection and film technology, which is used in disinfection, sanitary equipment for toilets, elevators, etc., can solve the problem of manual disinfection of transparent films, and achieve the effect of avoiding human-to-human cross infection and good disinfection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

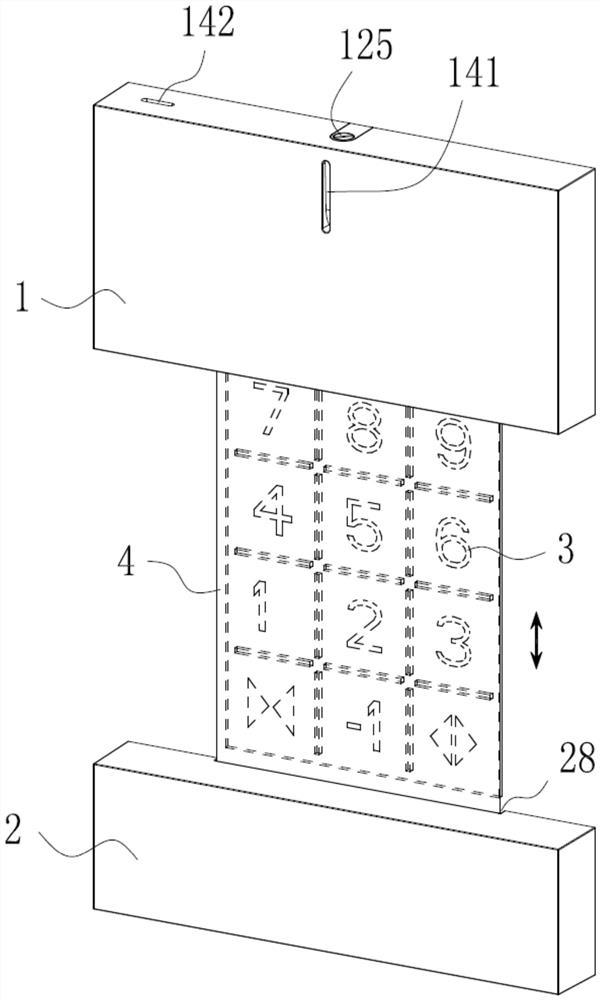

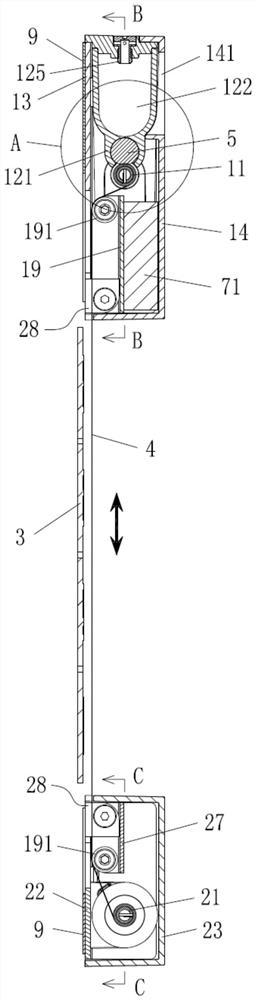

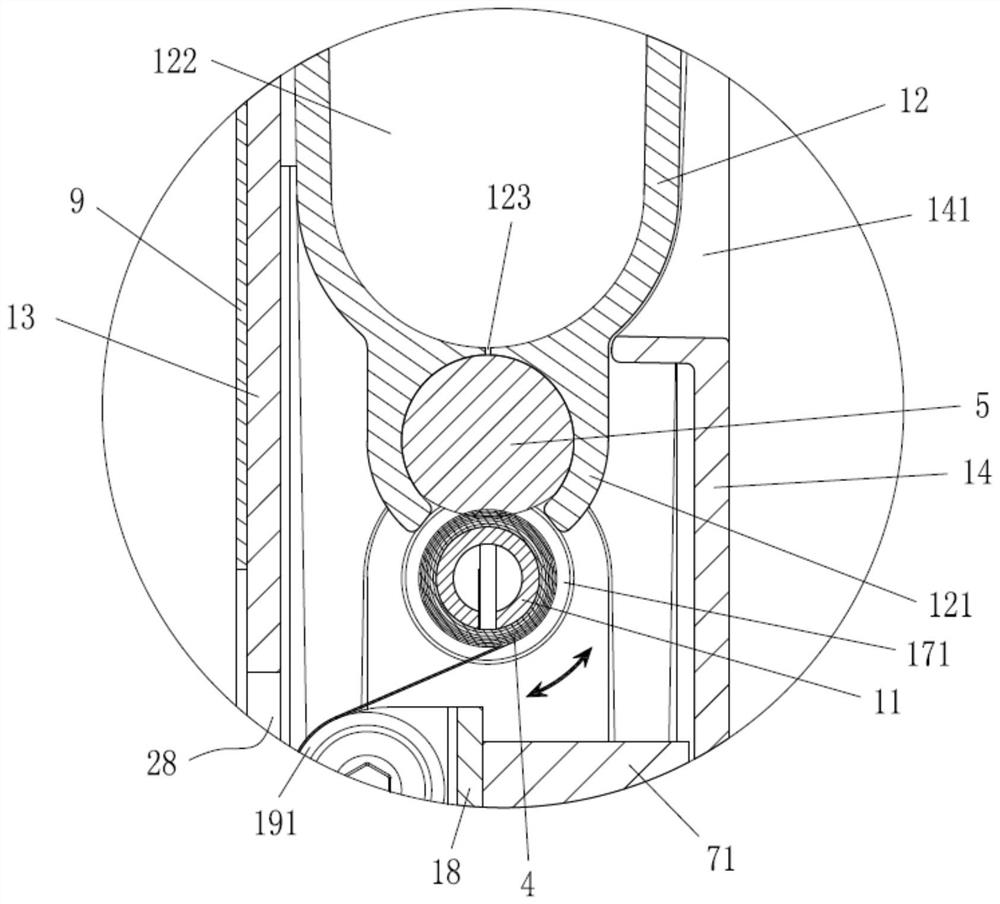

[0054] Please refer to Figure 1-9 , the present embodiment provides a film automatic sterilizer, comprising a first installation box 1, a second installation box 2 and a transparent film 4 for covering the surface of an elevator key panel 3, the first installation box 1 and the second installation box Two installation boxes 2 are installed on both sides of the elevator key panel 3 respectively. The inside of the first installation box 1 is provided with a first rotating shaft 11 that is wound and connected to one end of the transparent film 4, and the inside of the second installation box 2 is provided with a second shaft that is wound and connected to the other end of the transparent film 4. Shaft 21. The first installation box 1 is provided with a disinfectant absorbing part 5 which is in close contact with the transparent film 4 . The first rotating shaft 11 is connected with a motor 6 that can drive the first rotating shaft 11 to rotate and wind the transparent film 4 t...

Embodiment 2

[0079] refer to Figures 10-17 , this embodiment 2 is optimized on the basis of embodiment 1. Wherein, the places different from embodiment 1 mainly contain the following aspects:

[0080] In this second embodiment, the assembly method of the first installation box 1 and the second installation box 2 in the first embodiment is improved, and the first installation box 1 and the second installation box 2 are fixed by magnetic attraction. Quick and easy to assemble. Specifically, refer to Figure 10 , the first installation box 1 and the second installation box 2 are roughly in the shape of a cuboid. refer to Figure 15 ~ Figure 17 , the container assembly 12 is provided with two first magnet blocks 126, the first installation box 1 includes a third fixing frame 15 adapted to the container assembly 12, and the third fixing frame 15 is provided with The two first magnet blocks 126 are magnetically connected to the first metal bracket 153 . The second installation box 2 inclu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap