Workshop safety inspection rescue robot

A rescue robot and workshop safety technology, which is applied to manipulators, motor vehicles, tracked vehicles, etc., can solve the problems of casualties, high cost of manual inspection, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

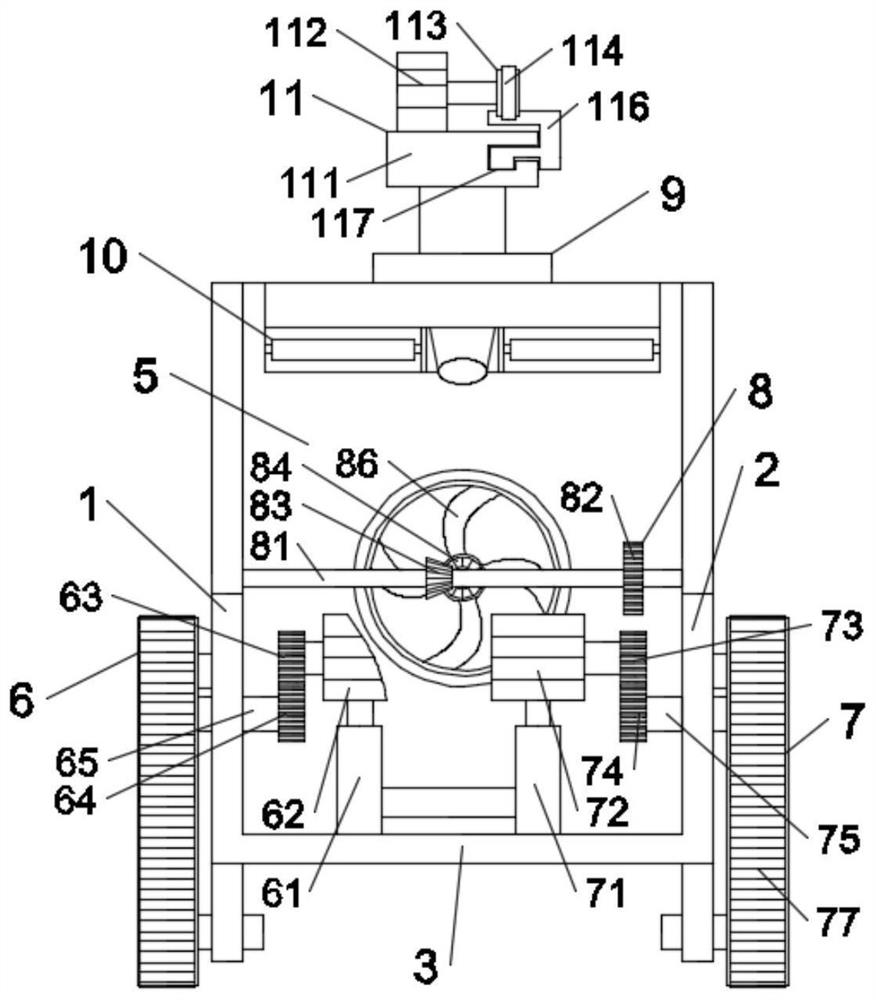

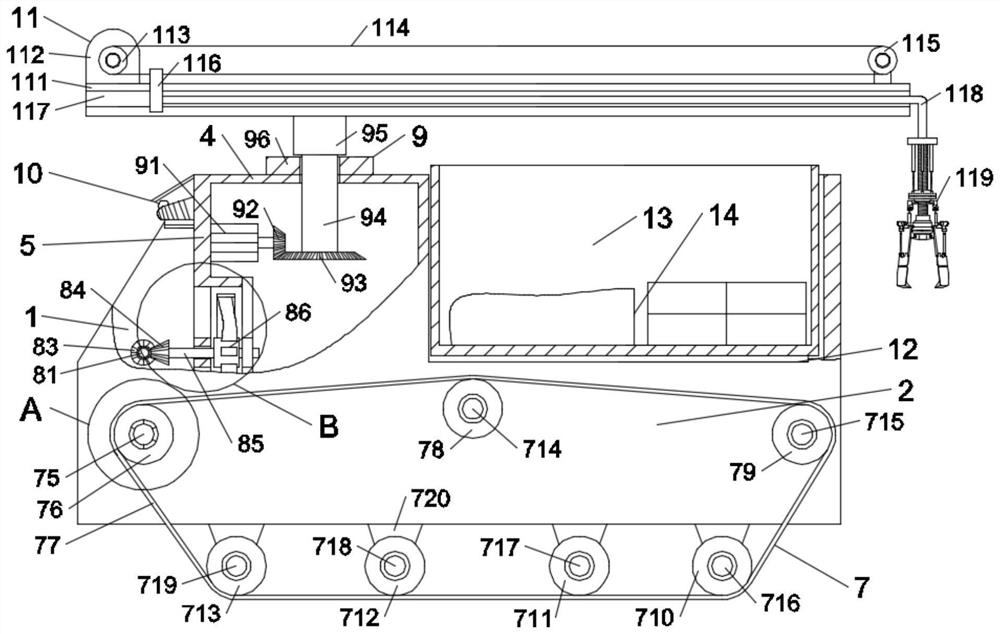

[0022] Such as Figure 1-Figure 4 As shown, in the embodiment of the present invention, a workshop safety inspection rescue robot includes a left side board 1 and a right side board 2, and a bottom board 3 and an upper board are connected between the left side board 1 and the right side board 2 4 and a vertical partition 5, the left side panel 1 and the right side panel 2 are respectively connected with a left steering device 6 and a right side steering device 7, and a fan device 8 is installed on the vertical partition 5, An inspection mechanism 10 is fixedly connected to the front of the vertical partition 5, and a rotating mechanism 9 is connected to the upper plate 4, and the rotating mechanism 9 is connected to a mechanical arm retractable mechanism 11. The upper plate 4, A transport space 12 is provided at the corresponding positions behind the left side plate 1 and the right side plate 2, and a cargo compartment 13 is housed in the transport space 12, and several differ...

Embodiment 2

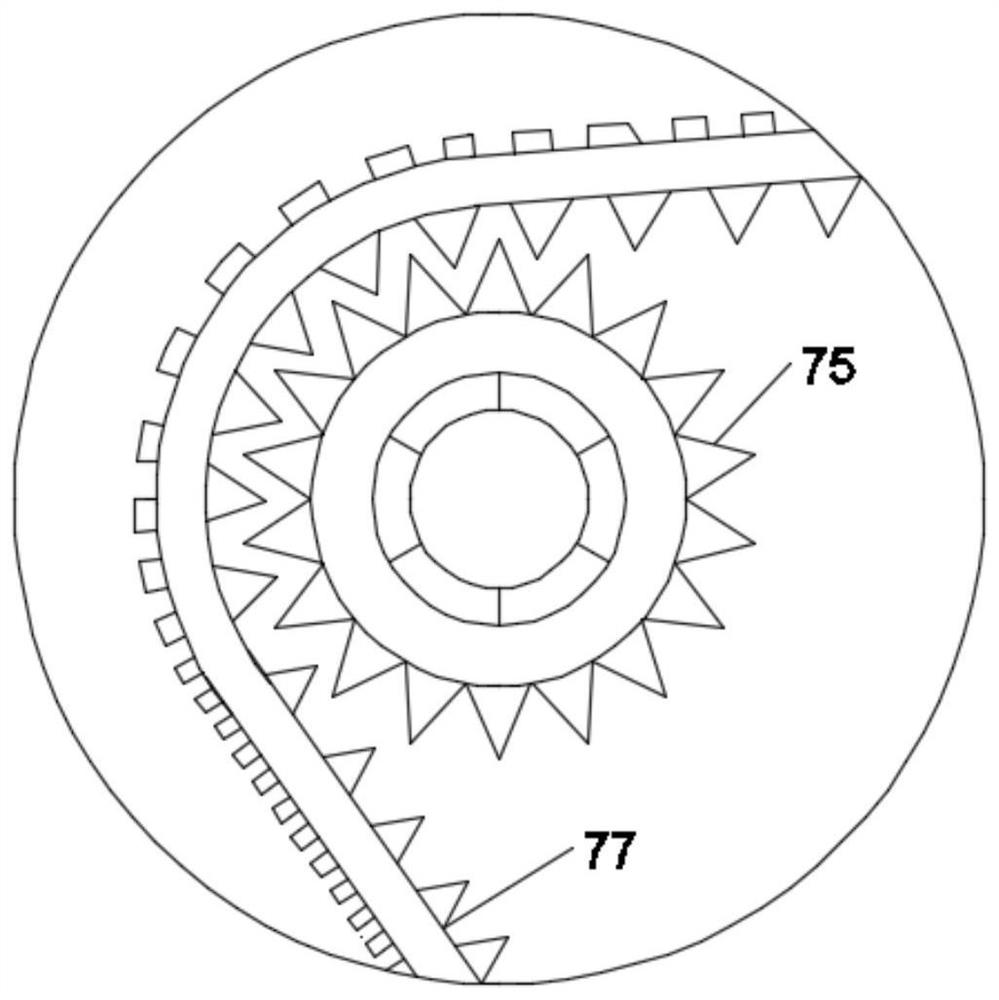

[0025] Such as Figure 1-Figure 4 As shown, in the embodiment of the present invention, the right steering device 7 includes a first telescopic member 71, the upper end of the first telescopic member 71 is fixedly connected with a first motor 72, and the first motor 72 is connected with a first Gear 73, the first gear 73 meshes with a second gear 74, the second gear 74 is connected to a first shaft 75, and one end of the first shaft 75 passing through the right side plate 2 is fixedly connected to a first sprocket 76, the first sprocket 76 is connected with the first track 77, and the first track 77 is connected with the second sprocket 78, the third sprocket 79, the fourth sprocket 710, the fifth sprocket 711, the Six sprockets 712 and the seventh sprocket 713, the second sprocket 78, the third sprocket 79, the fourth sprocket 710, the fifth sprocket 711, the sixth sprocket 712 and the seventh sprocket 713 are respectively connected There are a second shaft 714 , a third sha...

Embodiment 3

[0028] Such as Figure 1-Figure 4 As shown, in the embodiment of the present invention, the first rotating shaft 75, the second rotating shaft 714 and the third rotating shaft 715 are rotatably connected to the right side plate 2, and the second rotating shaft 714 is compared with the second rotating shaft 714 and the third rotating shaft 714. The installation position of the three rotating shafts 715 is a little higher, and the fourth rotating shaft 716, the fifth rotating shaft 717, the sixth rotating shaft 718 and the seventh rotating shaft 719 are respectively installed on four right rotating shaft seats 720 equally spaced in the horizontal direction. The right rotating shaft seat 720 is fixed on the bottom end of the right side plate 2 .

[0029]In the embodiment of the present invention, because the first crawler belt 77 is easily affected by gravity at the position of the second rotating shaft 714 and loosens and falls off, the installation position of the second rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com