A cable stranding machine for power cable production

A technology of power cable and stranding machine, which is applied in the direction of thin material handling, delivery of filamentary materials, transportation and packaging, etc., can solve the problems of complicated structure, and achieve the effect of reasonable structure design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

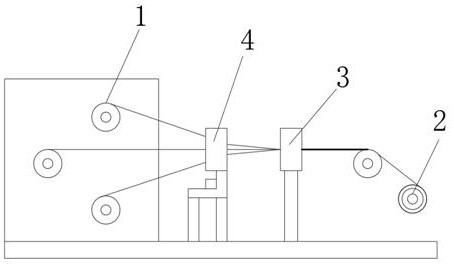

[0030] Refer to attached Figure 1-5 , a cable stranding machine for power cable production, comprising a plurality of pay-off rolls 1 and take-up rolls 2, a stranding structure 3 is provided between the pay-off rolls 1 and the take-up rolls 2, the An adjustable take-up structure 4 is provided between the pay-off roller 1 and the twisted structure 3 , and a sliding drive structure 5 is provided at the bottom of the adjustable take-up structure 4 .

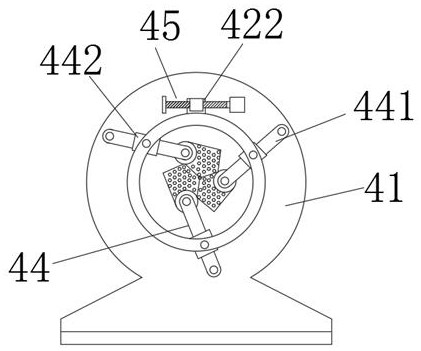

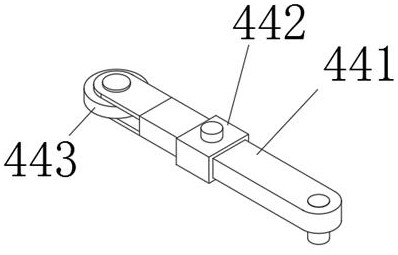

[0031] The adjustable take-up structure 4 includes a mounting plate 41, the center of which is a through hole, and a first rotating ring 42 is installed on one side of the mounting plate 41, and the first rotating ring 42 is supported by a plurality of evenly arranged The rod 421 is connected to the second rotating ring 43, and a take-up unit 44 is provided in the empty groove formed by two adjacent supporting rods 421, and a first moving block 422 is provided on one side of the first rotating ring 42, The first moving block 422 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com