Hydraulics and Loaders

A hydraulic system, full hydraulic technology, applied in the field of hydraulic systems and loaders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

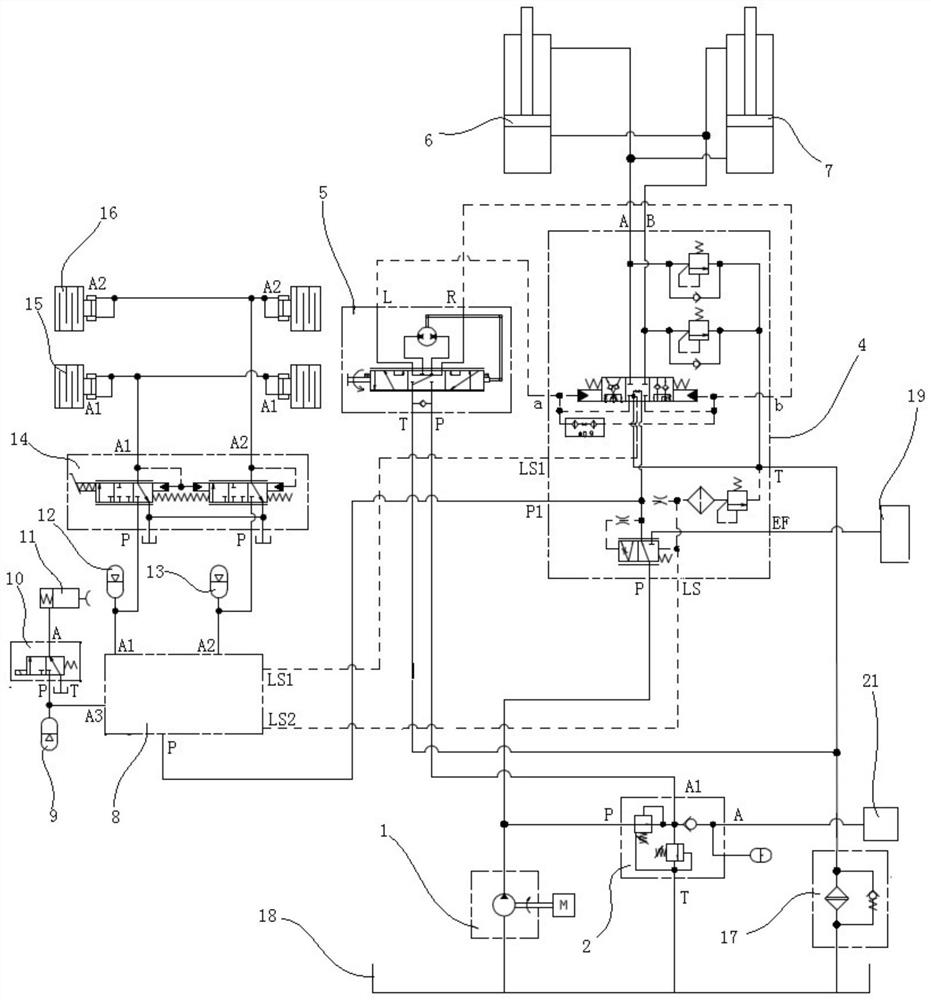

[0027] Specific embodiments are described below with reference to the accompanying drawings.

[0028] figure 1 A hydraulic system of a loader is shown. The hydraulic system includes a full hydraulic braking system, a steering system, and a working hydraulic system.

[0029] The full hydraulic braking system includes a brake pressure oil source, a service brake valve 14 , a service brake, a parking brake valve 10 , and a parking brake 11 connected in sequence through pipelines.

[0030] The service brake includes a front axle brake 15 and a rear axle brake 16 . The service brake valve 14 is a dual oil circuit brake valve whose two oil outlet ends are correspondingly connected to the front axle brake 15 and the rear axle brake 16 . The oil outlet end of the parking brake valve 10 is connected to the parking brake 11 through a pipeline.

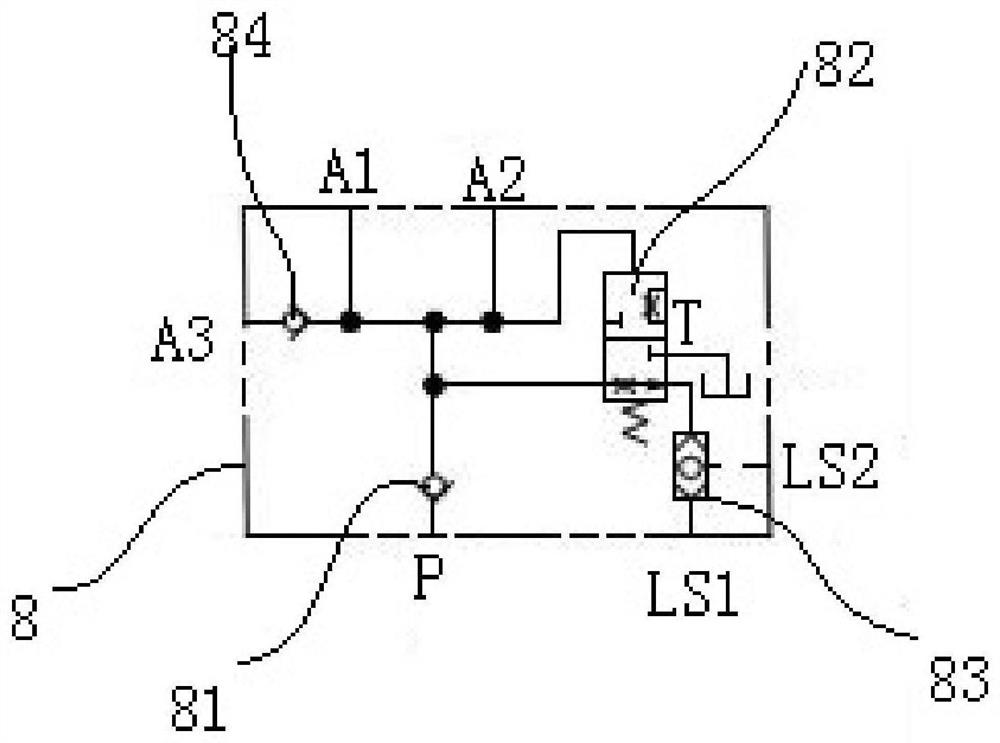

[0031] The brake pressure oil source includes a load-sensitive charging valve 8, a service brake accumulator, and a parking brake accumulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com