Vertical and horizontal dual-purpose fire extinguisher

A technology for both vertical and horizontal use and fire extinguisher, which is used in fire rescue and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

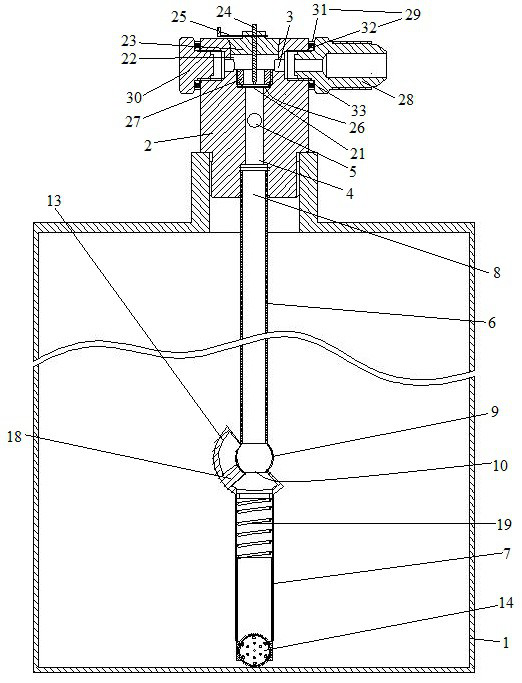

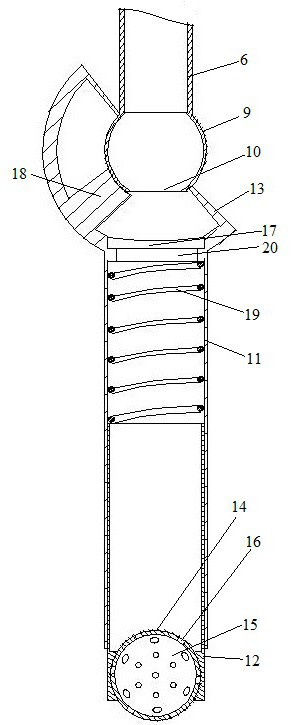

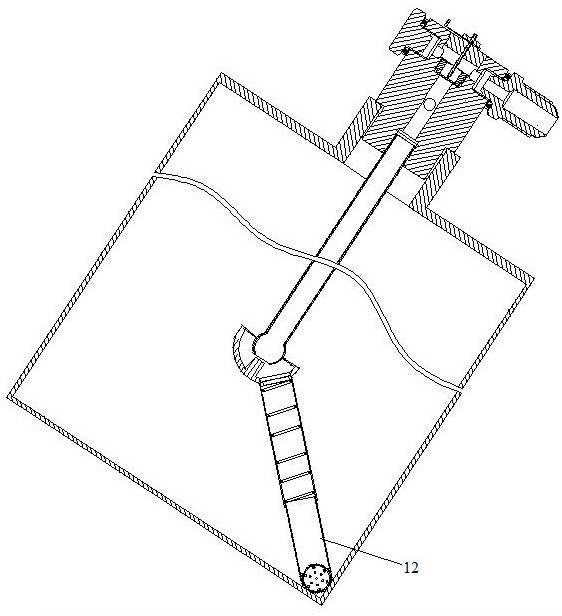

[0026] Embodiment one, see Figure 1 to Figure 4A vertical and horizontal fire extinguisher includes a fire extinguisher control valve and a fire extinguisher cylinder 1 with a valve connection port at the upper end. The fire extinguishing agent control valve includes a valve body 2 provided with a flow passage on-off control mechanism. The valve body is thread-tightly connected in the valve connection port. The valve body is provided with the fire extinguishing agent outlet 3 of the valve body part, the fire extinguishing agent inlet 4 of the valve body part and the pressure gauge connection interface 5, and the pressure gauge is connected in the pressure gauge connection during use. The fire extinguishing agent outlet of the valve body is communicated with the fire extinguishing agent inlet of the valve body through the fire extinguishing agent outflow channel. The flow channel channel control mechanism is used to make the connection between the fire extinguishing agent ou...

Embodiment 2

[0029] Embodiment 2 is different from Embodiment 1 in that: the junction of the side wall and the bottom wall of the fire extinguisher cylinder is provided with a support ring 34 extending along the circumferential direction of the fire extinguisher cylinder and located in the fire extinguisher cylinder for supporting and supporting rolling balls. A mirror layer is provided on the support surface of the support ring. An anti-off block 35 is provided on the thimble to prevent the thimble from falling off the connecting seat, and the anti-off block is located between the connecting seat and the partition film. The thimble is sleeved with a thimble drive spring 36 that drives the thimble to move toward the partition film so that the thimble pierces the partition film. Under the action of the thimble drive spring, the limit pin abuts against the connecting seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com