A high-efficiency and energy-saving weft detection device and method

A high-efficiency, energy-saving, detection device technology, used in measurement devices, force/torque/work measuring instruments, textiles and paper making, etc. Increased service life, ease of replacement, improved reliability and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

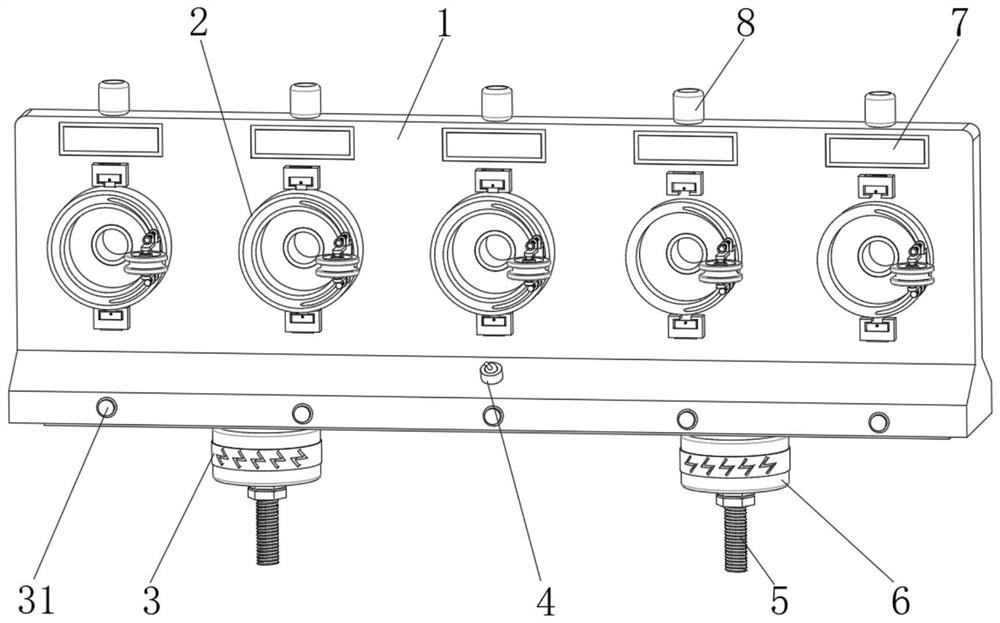

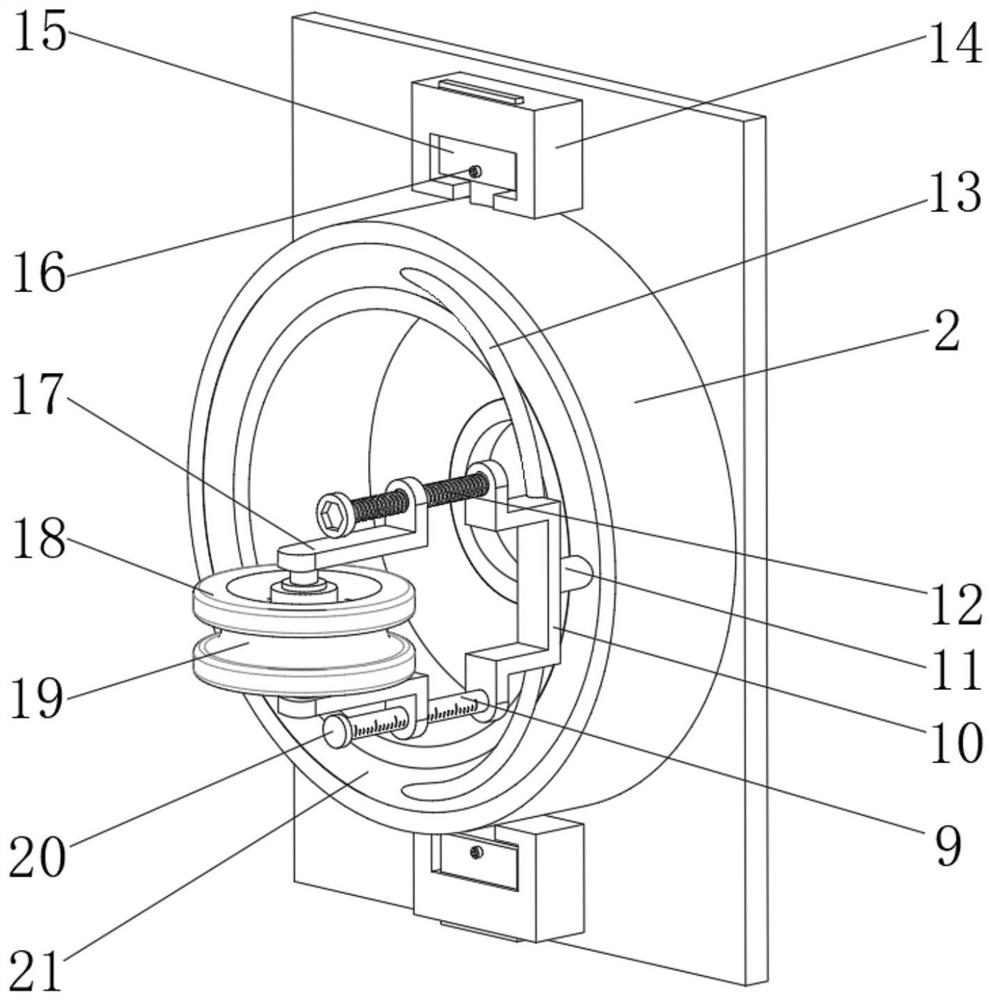

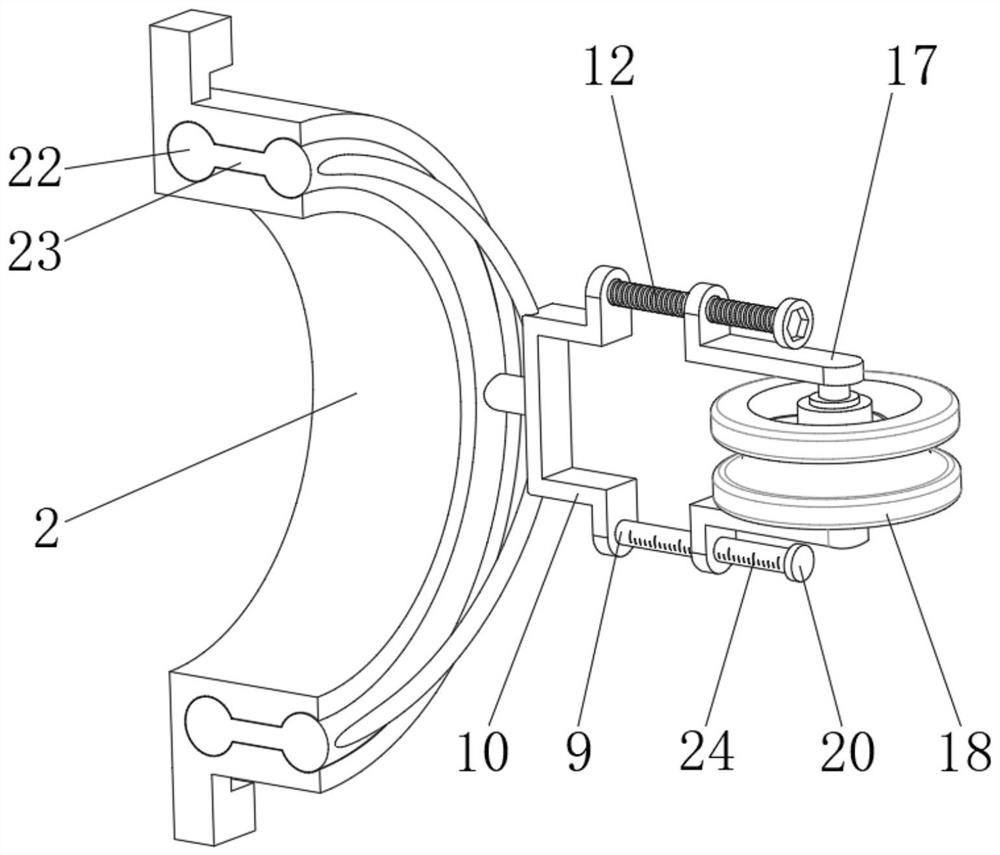

[0040] A high-efficiency and energy-saving weft yarn detection device, such as Figure 1-5As shown, it includes a main body 1 with more than two detection holes, the side of the main body 1 is provided with evenly distributed sliding seats 2, and the sliding seats 2 correspond to the positions of the detection holes; the main body 1 is also provided with a The control switch 31, through the control switch 31, the detection hole can be detected in real time or the detection circuit of the corresponding detection hole can be disconnected, so as to achieve the effect of energy saving; Concentric, the slider 21 includes two circular slip rings 22 and a bar-shaped slip ring 23, and the two circular slip rings 22 are integrally arranged at both ends of the bar-shaped slip ring 23; one side of the outer wall of the slider 21 passes through The main fixed rod 11 is fixed with the first installation frame 10, and the outer wall of the first installation frame 10 side is equipped with a...

Embodiment 2

[0050] A high-efficiency and energy-saving weft yarn detection method, which is realized by a high-efficiency and energy-saving weft yarn detection device, specifically includes the following steps:

[0051] S1: The user inserts the sliding seat 2 into the fixed seat 14 through the T-shaped block, and fixes it through the sliding block 15 and the jacking wire 16;

[0052] S2: Install and fix the main body 1 on the loom through the fixing stud 5;

[0053] S3: Pass the weft yarn through the detection hole and the guide groove 19 in sequence, and finally assemble it on the loom;

[0054] S4: Change the working state of the detection hole through the control switch 31 and the adjustment switch 4;

[0055] S5: Turn the sliding member 21 in the sliding seat 2, and adjust the guide wheel 18 to a suitable angle;

[0056] S6: Adjust the distance between the guide wheel 18 and the detection hole by rotating the adjustment screw 12, and observe the indication of the pressure sensor in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com