A film laying device for highway engineering construction

A technology of engineering construction and film laying device, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of damaging the road surface, unfavorable use, waste of light energy resources, etc., and achieve the effect of easy cleaning and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

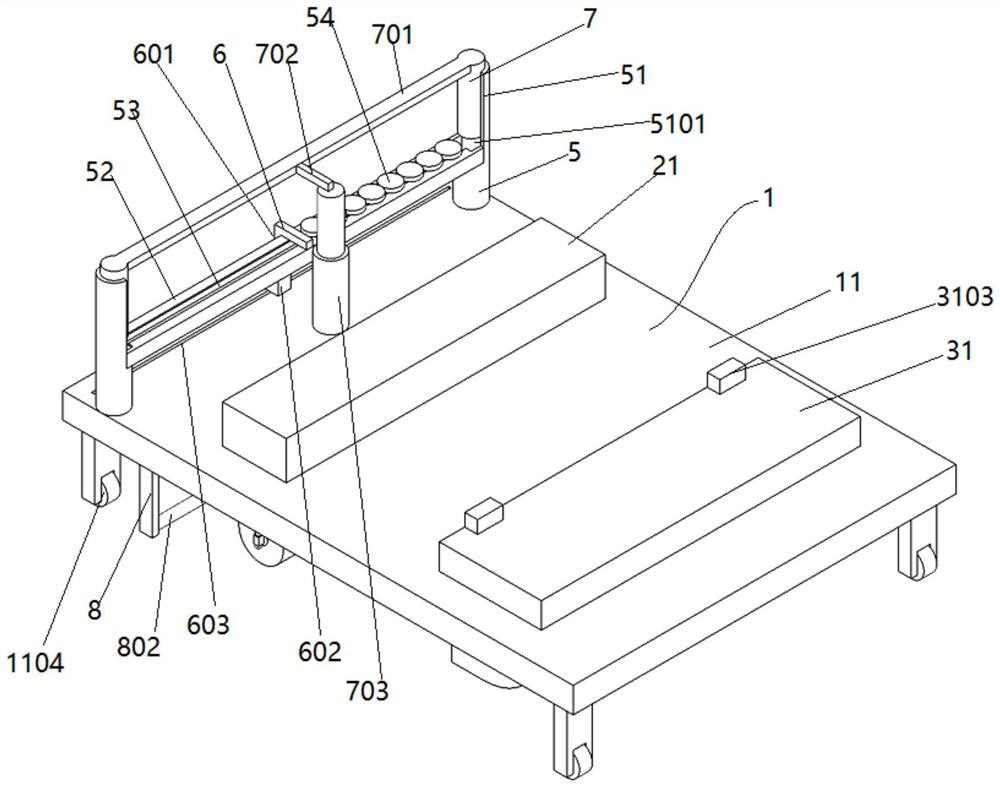

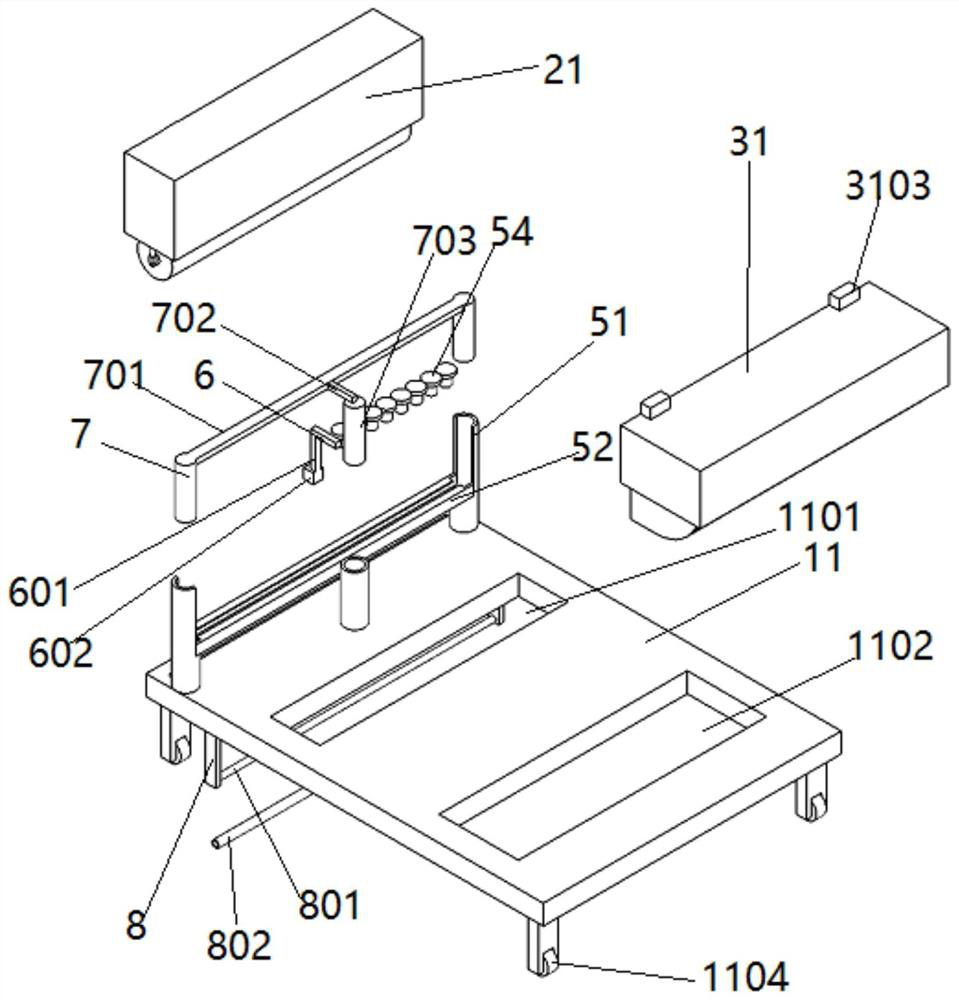

[0052] Such as Figure 1-6 As shown, a film laying device for highway engineering construction includes a mobile carrier 1, a roll-up film device 2 and a front cleaning device 3 arranged on the mobile carrier 1, and one end of the mobile carrier 1 is also provided with a die tight Solid device 4, and the automatic control system of controlling this device;

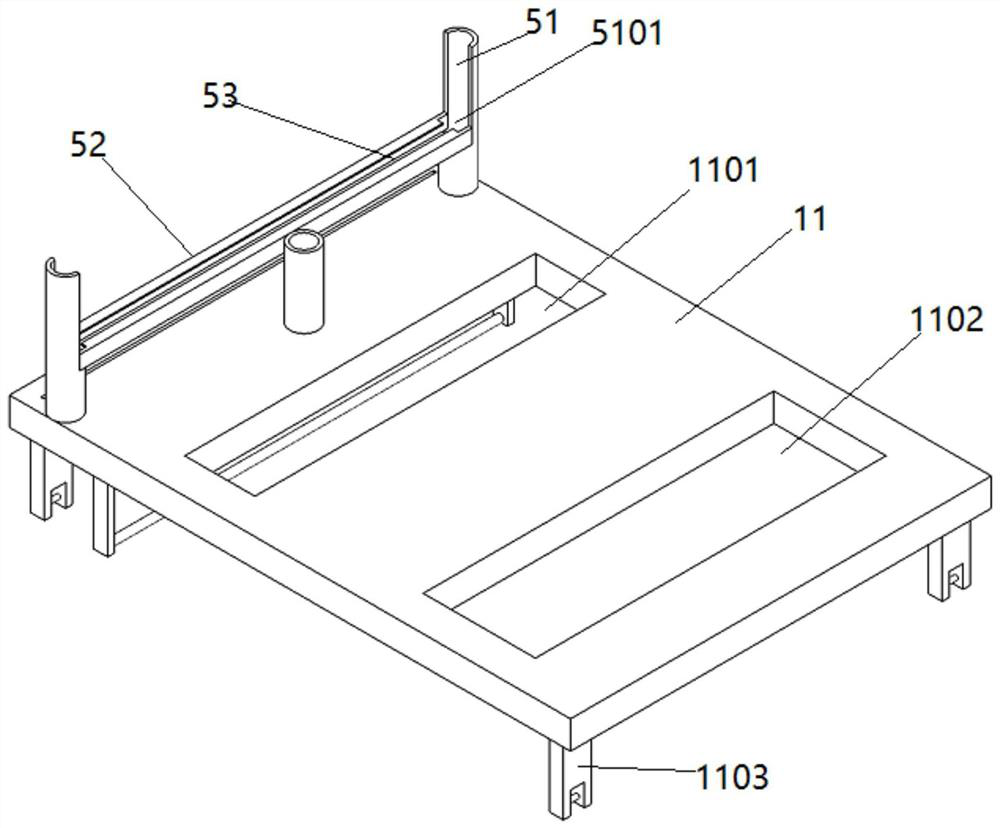

[0053] Wherein, the mobile carrier 1 includes a carrier substrate 11, a first foundation groove 1101 is opened on the carrier substrate 11, a second foundation groove 1102 is opened on one side of the first foundation groove 1101, and a first foundation groove 1102 is opened on one side of the first foundation groove 1101. Both the groove 1101 and the second base groove 1102 run through the carrier substrate 11; four support feet 1103 are fixedly connected to the bottom of the carrier substrate 11, and rollers 1104 are arranged at the bottom of the support feet 1103;

[0054] The first base tank 1101 is provided with a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com