A windproof and dust-suppressing adsorption baffle structure for traffic engineering construction

A traffic engineering, baffle structure technology, applied in protective equipment, buildings, etc., can solve the problem that the baffle structure does not have an adsorption effect, and achieve the effect of ensuring windproof and dust suppression performance and connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

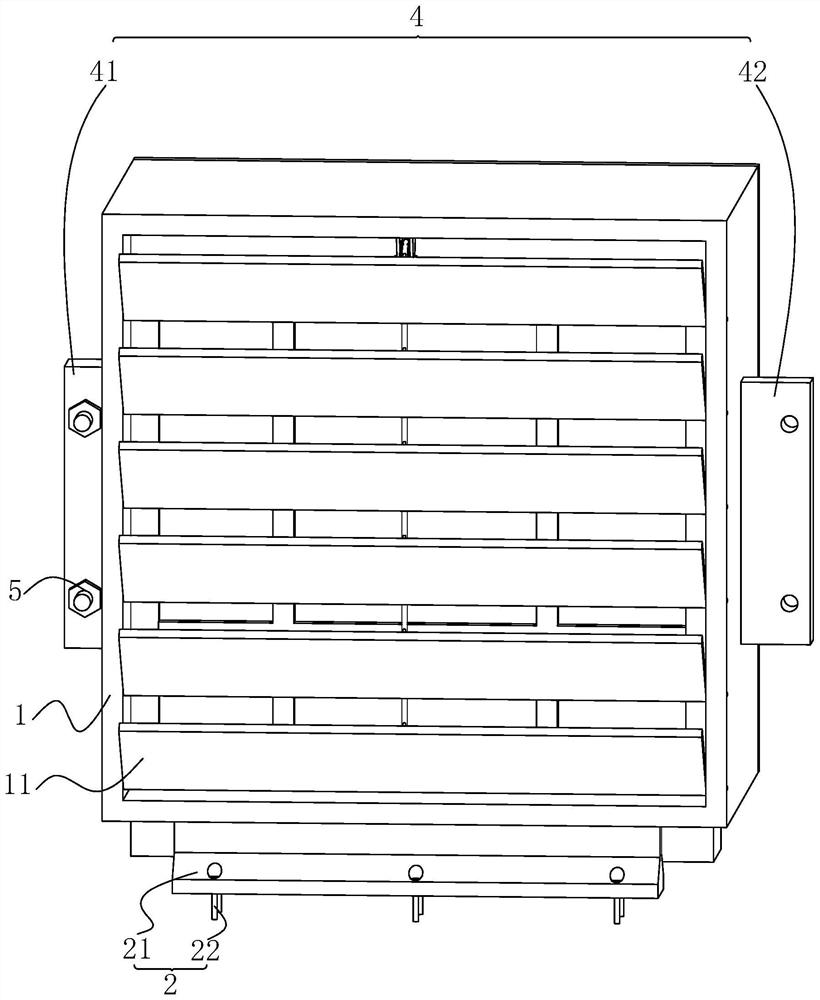

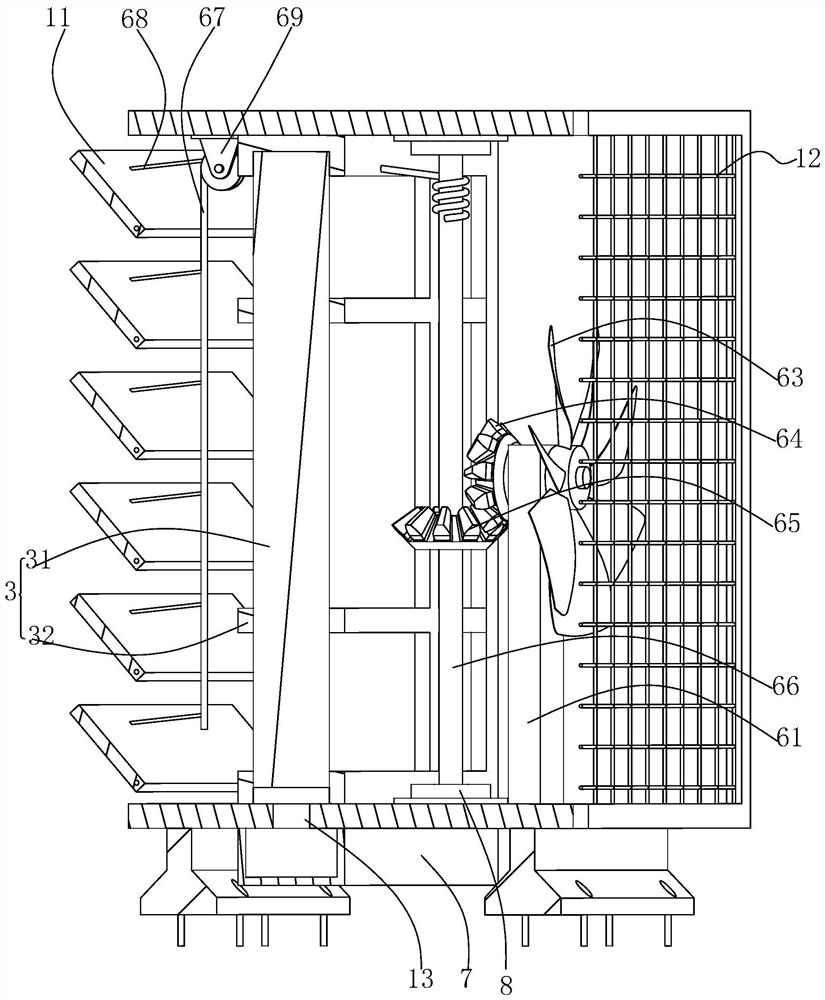

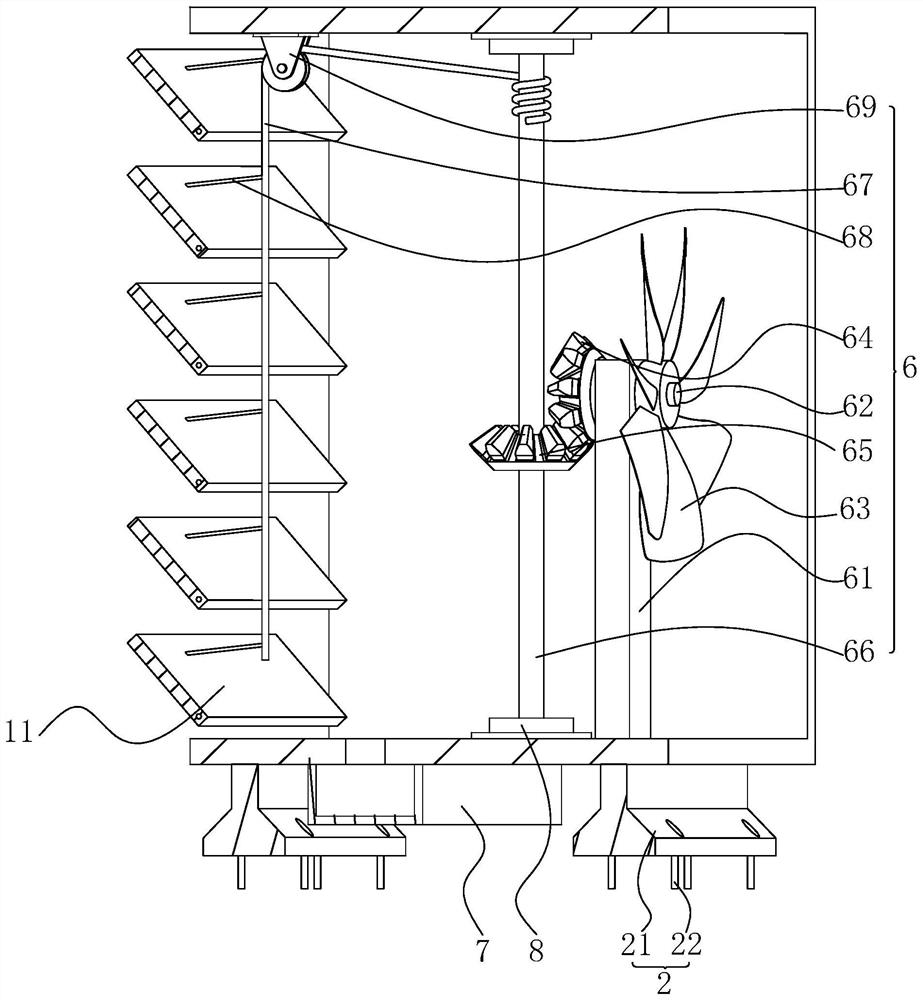

[0030] The following is attached Figure 1-3 The application is described in further detail.

[0031] The embodiment of the present application discloses a windproof and dust-suppressing adsorption type baffle structure for traffic engineering construction.

[0032] refer to figure 1 and figure 2 , traffic engineering construction windproof dust suppression adsorption type baffle structure includes fixed frame 1, fixed frame 1 is a rectangular plate-shaped structure, one end surface of fixed frame 1 is provided with a stop baffle 11 for windproof, the length direction of stop baffle 11 is from the bottom The end to the top is gradually inclined to the side away from the fixed frame 1, and the angle between the side wall of the stop plate 11 close to the fixed frame 1 and the fixed frame 1 is always less than 90°, and the circumference of the stop plate 11 and the fixed frame 1 Vertical to the inner wall, the remaining end of the fixed frame 1 is fixedly connected with a du...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap