Municipal pipeline dredging device with adjustable working diameter and implementation method

A technology of municipal pipelines and working diameters, applied in water supply devices, cleaning sewer pipes, waterway systems, etc., can solve problems such as inconvenient storage, inability to fold and adjust mobile devices, scraping and breaking of roller brackets, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

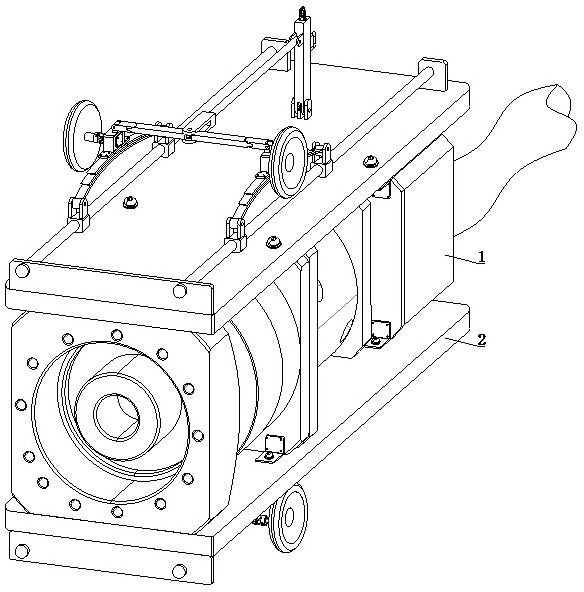

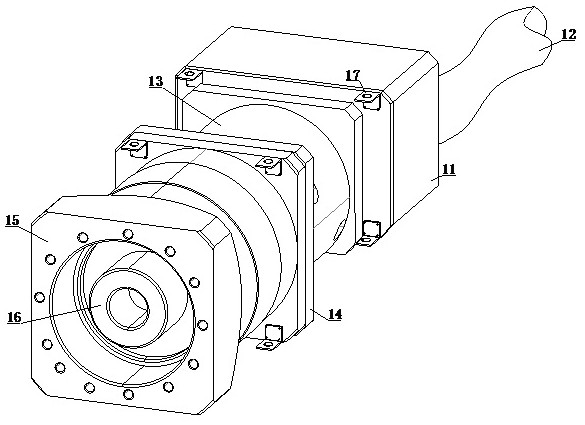

[0037] see Figure 1-2, a dredging device for municipal pipelines with adjustable working diameter, comprising a dredging head 1 and a moving device 2, the outer upper and lower ends of the dredging head 1 are equipped with a moving device 2, and the dredging head 1 includes a chassis 11, a connecting pipe 12 , water pipe 13, connecting piece 14, water spray head 15, water spray hole 16 and right-angle piece 17, one end side of cabinet 11 is equipped with connecting pipe 12, and the other end of cabinet 11 is equipped with water pipe 13, and the other end of water pipe 13 One end is equipped with a connecting piece 14, the other end of the connecting piece 14 is equipped with a water spray head 15, the other end side of the water spray head 15 is provided with a water spray hole 16, the outer surface of the cabinet 11 is equipped with a right-angle piece 17, the right-angle piece 17 The upper end is equipped with mobile device 2.

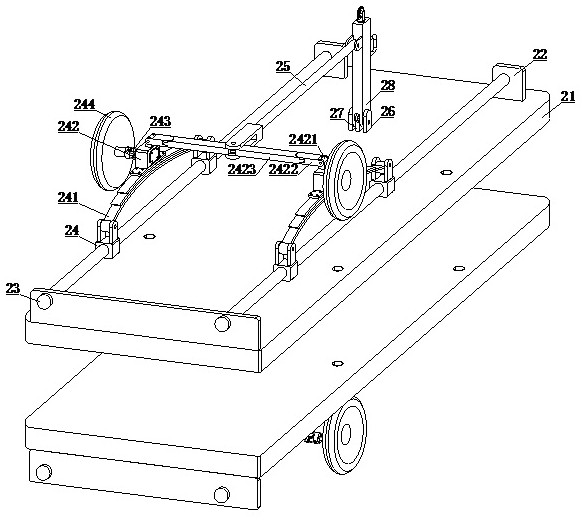

[0038] see Figure 3-4 , the moving device ...

Embodiment approach

[0040] The present invention provides another technical solution: a method for implementing a municipal pipeline dredging device with adjustable working diameter, comprising the following steps:

[0041] S01: Place the dredging head 1 and the mobile device 2 on the ground and make connections;

[0042] S02: Pull the handle 284 upwards according to the diameter of the municipal pipeline, so that the limit rod 28422 can fall off from the limit hole 271 at the lowermost end of the angle plate 27;

[0043] S03: pull the handle 284 backward at this time, the handle 284 can drive the support assembly 28 to rotate on the outer surface of the angle plate 27, and the lower end of the support assembly 28 is in the process of rotation, and one end of the connecting rod 25 is pulled by the support assembly 28 , while the connecting rod 25 pulls the second rotating rod 2423, the second rotating rod 2423 pushes the first connecting head 2421 outward, and the first connecting head 2421 makes...

Embodiment 2

[0046] see Figure 1-2 , a dredging device for municipal pipelines with adjustable working diameter, comprising a dredging head 1 and a moving device 2, the outer upper and lower ends of the dredging head 1 are equipped with a moving device 2, and the dredging head 1 includes a chassis 11, a connecting pipe 12 , water pipe 13, connecting piece 14, water spray head 15, water spray hole 16 and right-angle piece 17, one end side of cabinet 11 is equipped with connecting pipe 12, and the other end of cabinet 11 is equipped with water pipe 13, and the other end of water pipe 13 One end is equipped with a connecting piece 14, the other end of the connecting piece 14 is equipped with a water spray head 15, the other end side of the water spray head 15 is provided with a water spray hole 16, the outer surface of the cabinet 11 is equipped with a right-angle piece 17, the right-angle piece 17 The upper end is equipped with mobile device 2.

[0047] see Figure 3-4 , the moving device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com