System for injecting bypass air to decrease air film cold air temperature of aero-engine

An aero-engine and engine technology, which is applied to the cooling of the engine, the cooling system of the power plant, and engine components, can solve the problems of large mass, high storage and maintenance costs, and achieve the effect of reducing the level of infrared signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

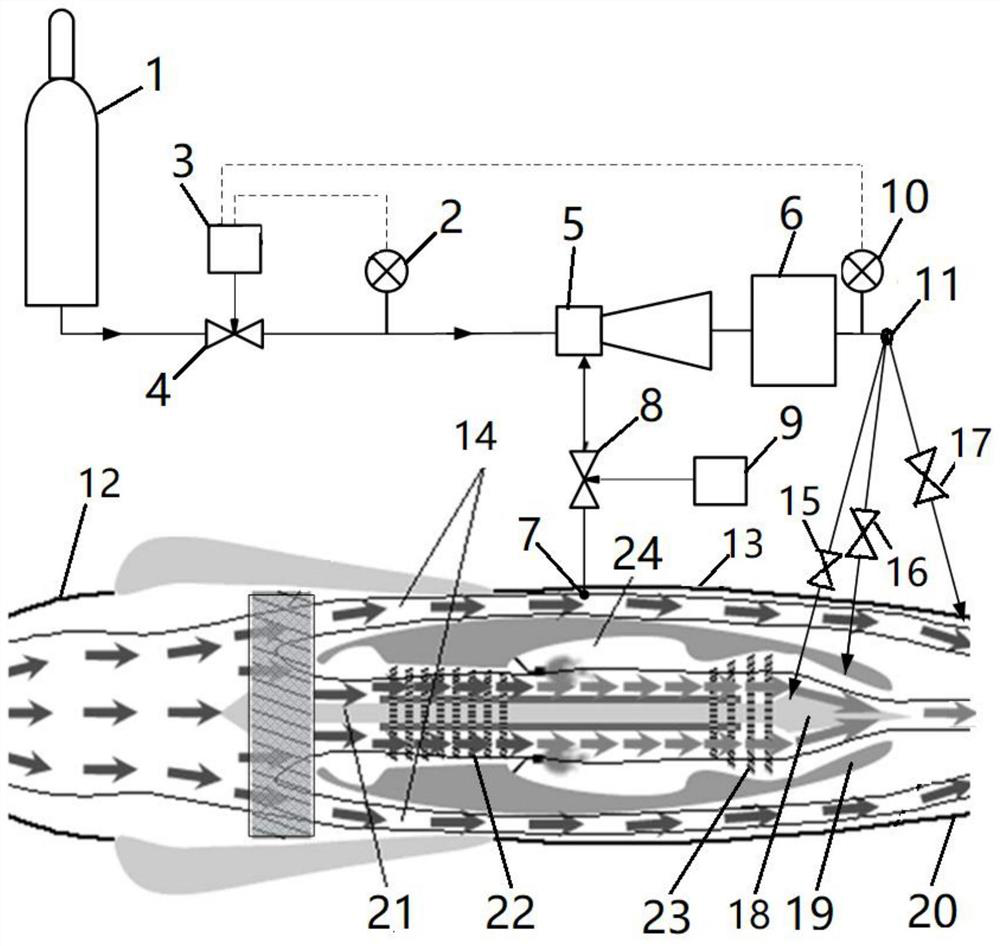

[0026] A system for injecting extraneous air to reduce the temperature of air-cooled air in an aero-engine according to an embodiment of the present invention. For its structure, see figure 1 , the system consists of:

[0027] The high-pressure cooling working medium storage container 1 is arranged inside the aircraft (the aircraft is not shown in the figure) and outside the engine 12 .

[0028] The buffer mixing chamber 6 is arranged inside the aircraft and outside the engine 12 .

[0029] The suction port 7 is opened on the wall surface 13 of the outer duct of the engine 12 .

[0030] The air film cold air injection port 11 is located on the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com