Auxiliary supporting equipment for storing weight type electronic products

An electronic product and auxiliary support technology, applied in tool storage devices, manufacturing tools, etc., can solve the problems of inconvenient storage operations for operators, single product protection measures, poor protection effects, etc. The effect of convenient storage and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

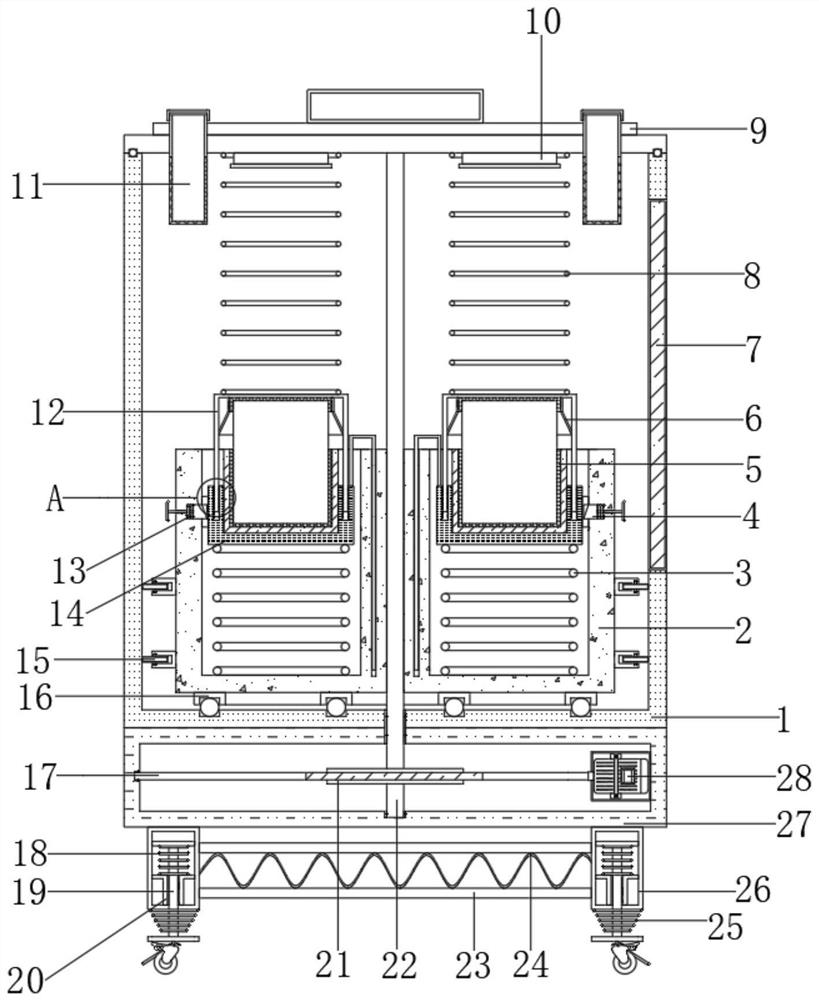

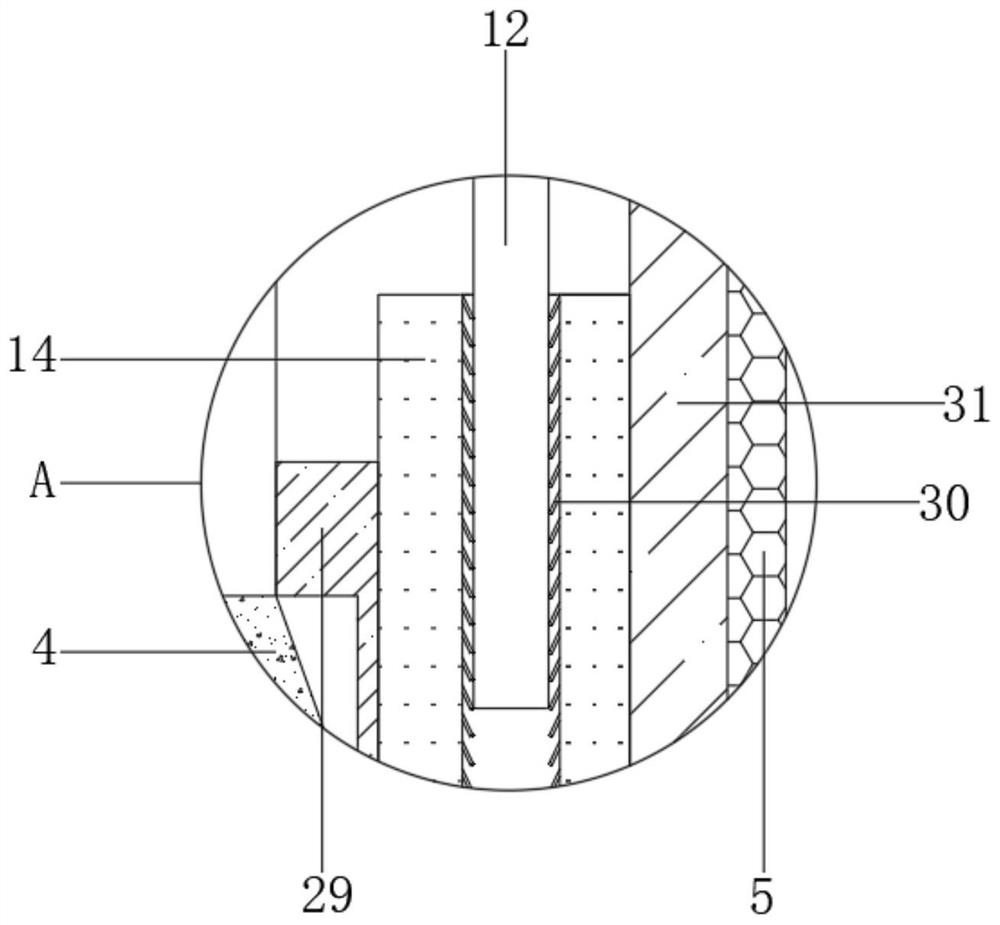

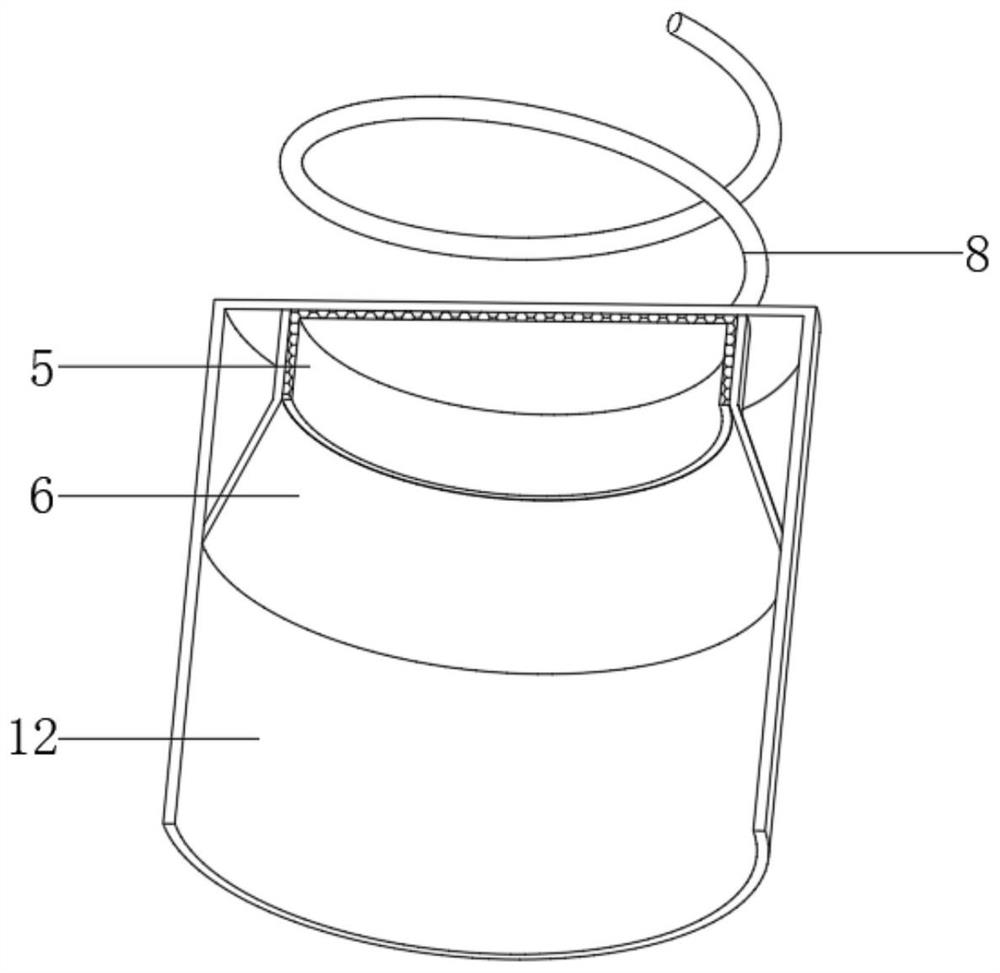

[0030] refer to Figure 1-5 , an auxiliary supporting device for storing heavy electronic products, comprising a bottom cavity base 27 with a buffer mechanism fixedly installed at the four corners of the bottom outer wall, a storage box 1 fixed to the top outer wall of the bottom cavity base 27 by bolts, the storage box 1 and the bottom cavity base The opposite side of 27 is connected with the same rotating column 22 through bearing rotation, and the end of rotating column 22 close to the inner bottom of storage box 1 is welded with tray block 2, and the top of tray block 2 is all opened with equidistantly distributed storage chambers, And the inner bottom of storage chamber is all welded with support spring 3, and the top of support spring 3 is all welded with outer holder 14, and the inner bottom of outer holder 14 is fixed with inner holder 31 by bolt, and the outer wall of outer holder 14 top is close to One side of the storage cavity is welded with an L-shaped positioning...

Embodiment 2

[0041] refer to figure 1 with Figure 5 , an auxiliary supporting device for storing heavy electronic products. Compared with Embodiment 1, this embodiment also includes a conical coil spring 25 welded to the outer wall of the bottom of the damping cylinder 26 .

[0042] When the present invention is used: the setting of the conical coil spring 25 is utilized, and the buffer mechanism plays a buffering role. The purpose of product safe storage effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com