A two-way synchronization system for the content of the current vehicle and the shunting operation plan in a graphical scene

A technology of operation planning and two-way synchronization, which is applied to the control system of the transportation center, railway car body components, railway signals and safety, etc., and can solve the problems of poor timeliness, inability to edit shunting operation plans, and unfavorable graphical shunting operation plan preparation Problems such as system promotion and application, to achieve the effect of reducing workload, shortening revision time, and improving planning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

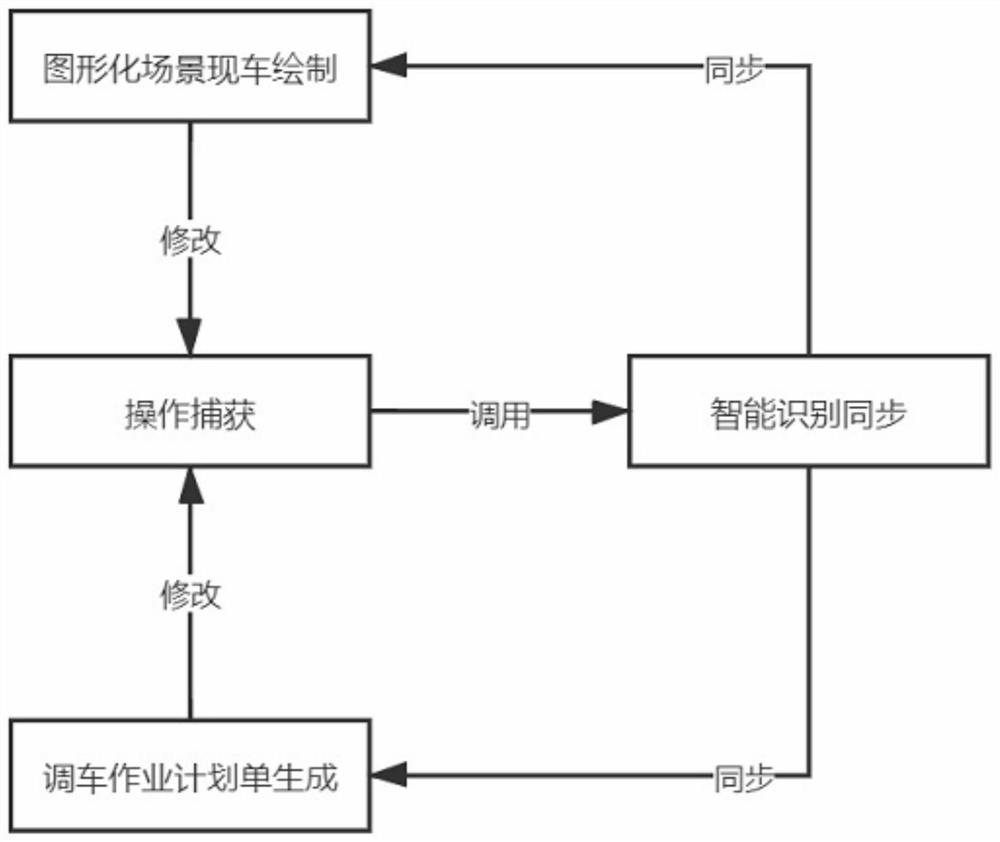

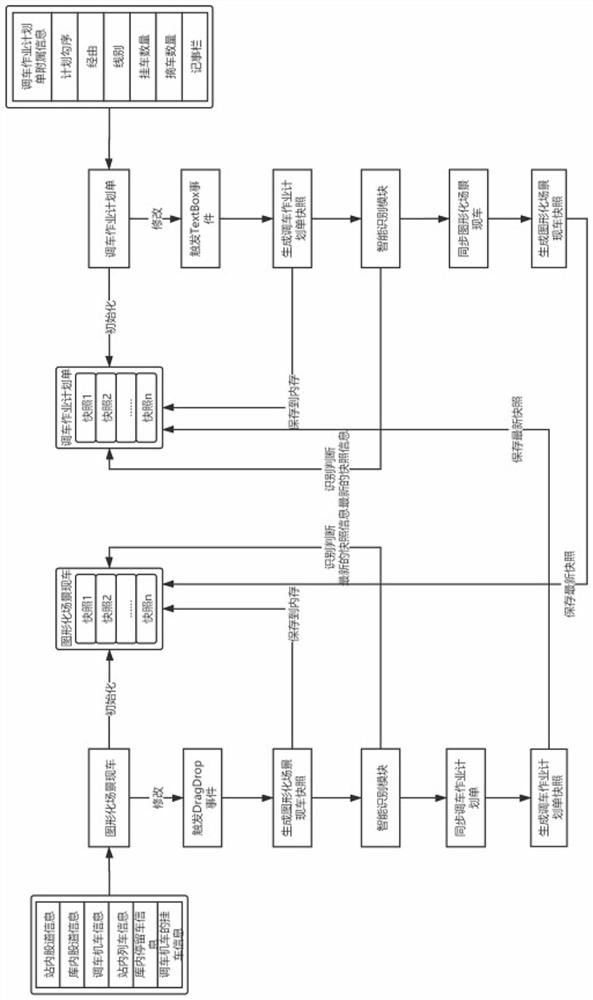

[0023] The two-way synchronization system for the content of the graphic scene vehicle spotting and shunting operation plan of the present invention is as follows: figure 1 shown, including:

[0024] (1) Graphical scene drawing module: it is used to read the information of the train track in the station, the track information in the depot, the shunting locomotive information, the train information in the station, the parking car information in the depot, and the trailer information of the shunting locomotive from the memory. And the scene that needs to be displayed is drawn to the system interface by means of Windows gdi.

[0025] Track information in the station: including track type, track length, and track number.

[0026] Stock channel information in the warehouse: including stock channel type, stock channel number, and stock channel direction.

[0027] Shunting locomotive information: including shunting name, shunting train number, shunting machine model.

[0028] Trai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com