Motorcycle vibration reduction type frame

A motorcycle and frame technology, which is applied in the field of motorcycle vibration-damping frames, can solve problems affecting driving comfort, driving safety, large high-frequency vibration, and complex load changes, etc., to ensure driving comfort and safety Sex, increase the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

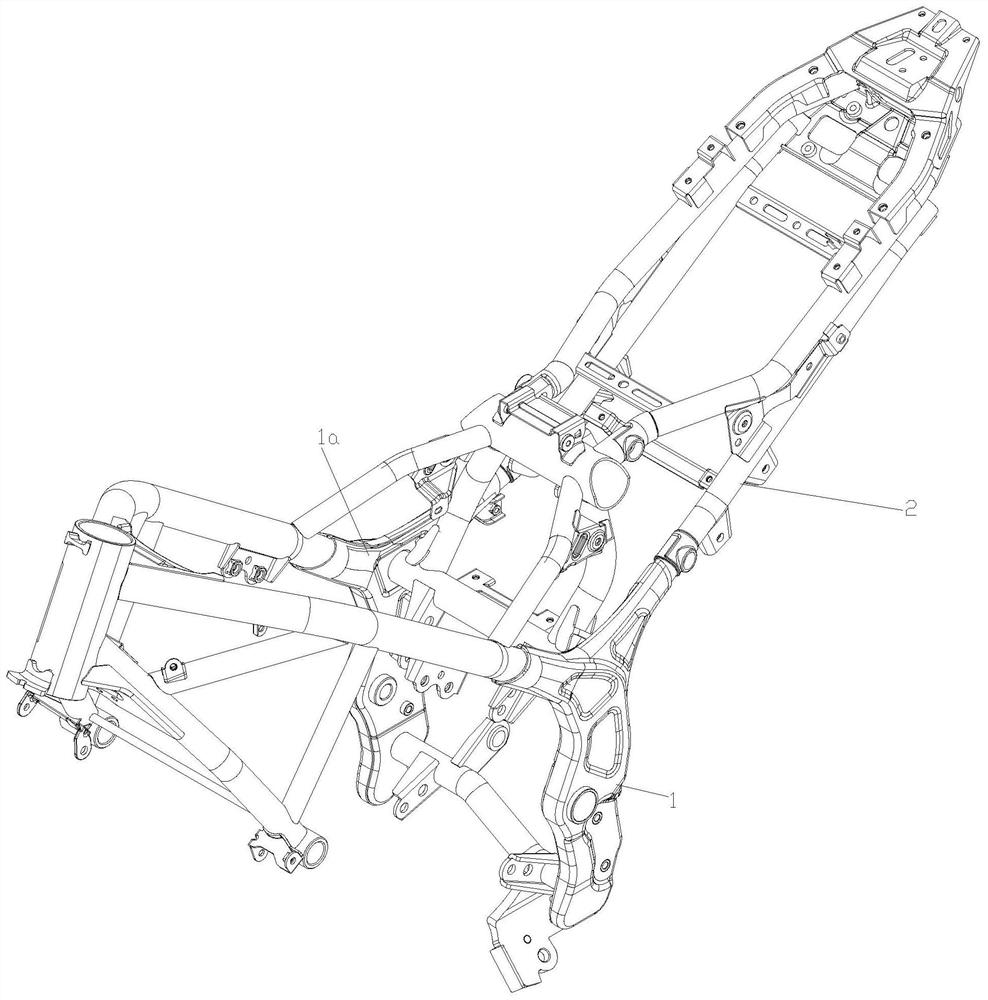

[0017] figure 1 It is an internal view of the large plate of the vehicle frame of the present invention, figure 2 It is the structure diagram of the vehicle frame of the present invention, as shown in the figure: the motorcycle vibration-absorbing type vehicle frame of the present embodiment includes a vehicle frame large plate 1 and a vehicle frame beam assembly 2 composed of vehicle frame beams, and the vehicle frame is large The plate 1 is a sandwich structure, and the inner space of the sandwich structure is filled with a layer of vibration-damping material 13; as shown in the figure, in the existing structure, the large plate 1 of the frame is fixed to the corresponding frame beams forward and backward respectively. Connection, of course, after the large plate 1 of the frame is installed on the frame, it is two basically symmetrical left and right. As shown in the figure, the large plate 1a on the right side belongs to the existing installation structure and method, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com