Combined type roll-on roll-off lightering ferry

A combination and ferry technology, which is applied in the direction of ferry, ship parts, ship construction, etc., can solve the problems of large space, inconvenient land storage and transportation, and heavy weight of a single unit, so as to achieve good anti-sinking performance and reduce Navigation water resistance, the effect of meeting the transportation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

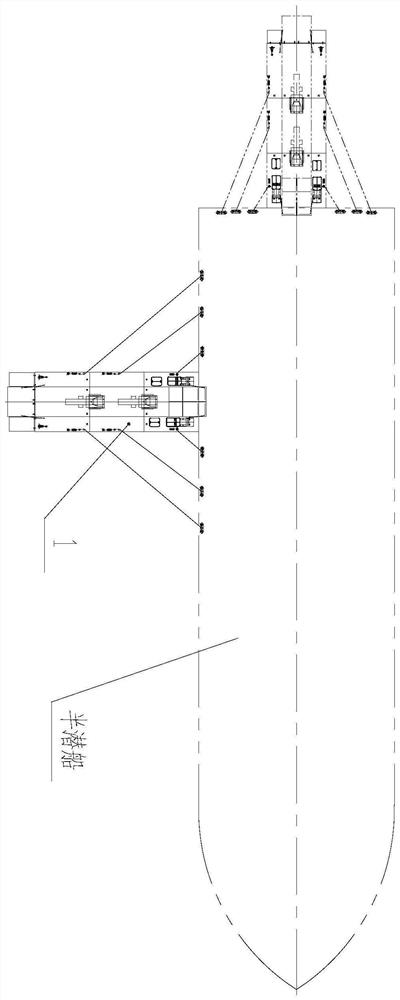

[0024] This embodiment provides a combined roll-on-roll-off barge ferry, which is composed of two floating tanks connected vertically and horizontally. Semi-submersible ship ro-ro transfer and self-propelled landing on the beach.

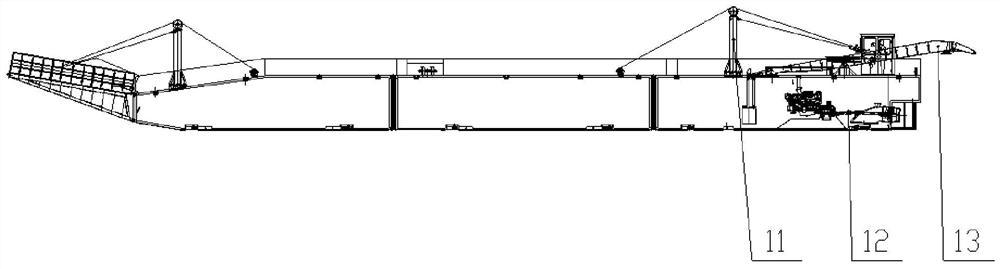

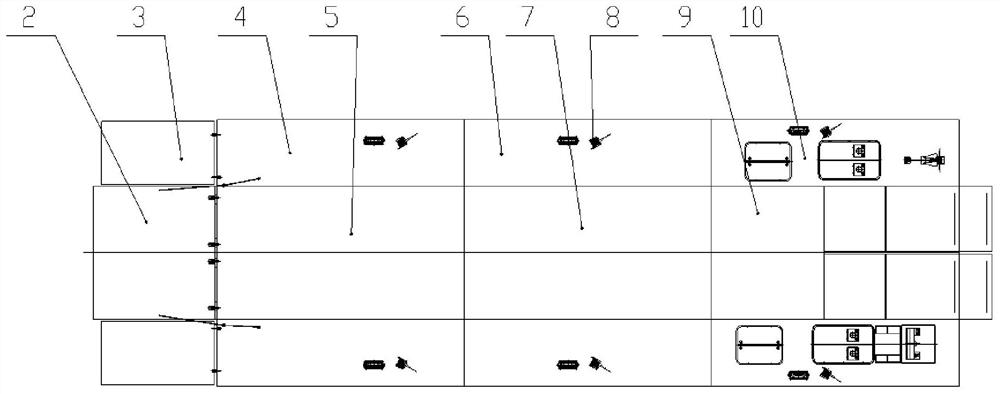

[0025] Such as figure 1 and 2 As shown, the ro-ro barge ferry 1 includes: a beach boarding springboard 2, a diversion box 3, a bow side box 4, a bow middle box 5, a middle side box 6, a middle middle box 7, a mooring system 8, and a stern middle box 9. Stern box 10, gangway lifting device 11, power propulsion system 12 and transfer gangway 13;

[0026] The connection relationship of the ro-ro barge ferry 1 is as follows: the bow side box 4, the bow middle box 5, the middle side box 6, the middle middle box 7, the stern middle box 9 and the stern side box 10 all adopt independently sealed buoyant boxes, three A total of twelv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com