Rotary wallboard leveling structure of fabricated wall

A rotary and assembled technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of loose installation and the inability to accurately control the adjustment distance of the leveling structure, so that it is not easy to loosen, the wall panel installation structure is stable, Adjust the distance to control the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

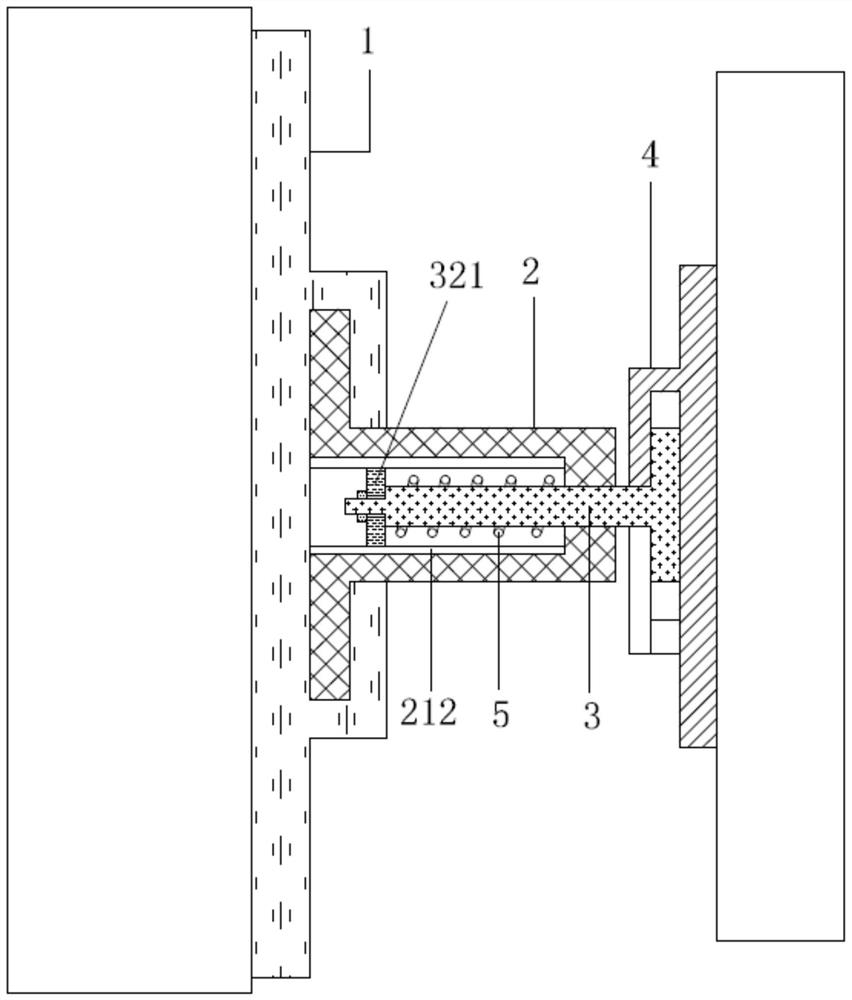

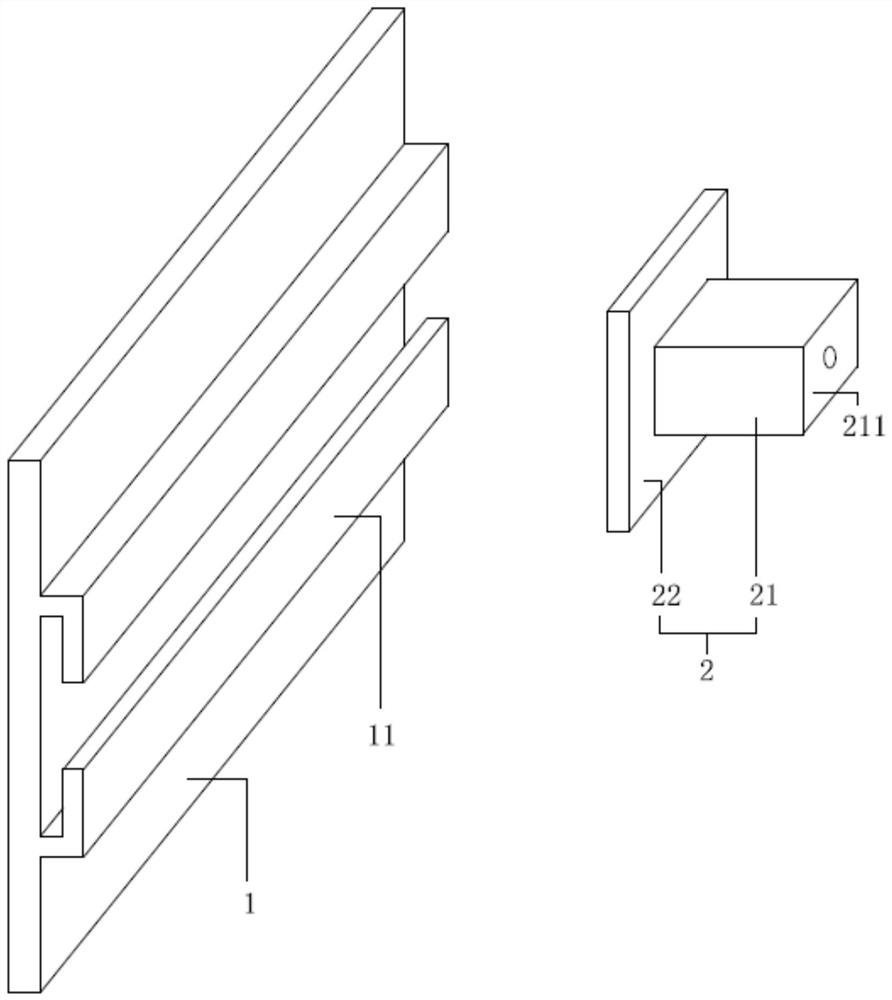

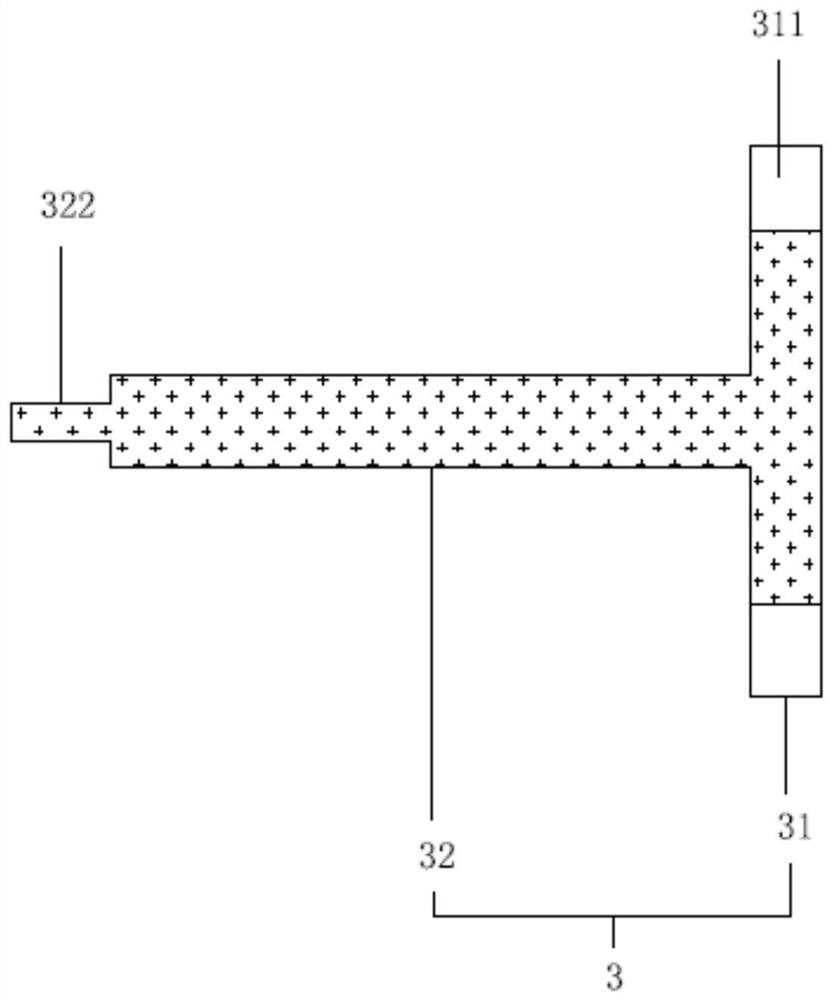

[0026] see Figure 1 to Figure 7 , the figure shows a rotating wall panel leveling structure for an assembled wall provided by Embodiment 1 of the present invention, including a mounting base 1, a connecting piece 2, a leveling piece 3 and a hooking piece 4, and the mounting base 1 Fixedly installed on the base of the wall, the connecting piece 2 is slidably connected to the mounting base 1, and the connecting piece 2 is provided with a columnar raised portion 21, and the leveling piece 3 includes an adjusting plate 31 and a screw 32, and the screw 32 penetrates the raised portion part 21, the screw rod 32 is screwed on the end plate 211 of the raised part 21, the screw rod 32 is sleeved with a spring 5, and the end of the screw rod 32 is provided with a baffle plate 321, and one end of the spring 5 is against the baffle plate 321, The other end is against the back of the end plate 211 , the hook 4 is fixedly mounted on the wallboard, and the hook 4 is hooked on the adjustment...

Embodiment 2

[0034] see Figure 1 to Figure 7 , the figure shows a rotating wall panel leveling structure of an assembled wall provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments The inner wall of the raised part 21 is provided with a plurality of ribs 212 arranged in the circumferential direction, and the edge of the baffle 321 is provided with a slot 3211 corresponding to the ribs 212 .

[0035] The ribs provided in the raised portion can further ensure smooth sliding of the baffle plate, thereby ensuring smooth movement of the screw rod and firm installation.

Embodiment 3

[0037] see Figure 1 to Figure 7 , the figure shows a rotating wall panel leveling structure of an assembled wall provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments : the adjusting plate 31 is a circular plate; the adjusting plate 31 is provided with several notches 311 arranged in the circumferential direction.

[0038] The adjustment plate is a circular plate, and after the adjustment plate is rotated and leveled, it can be articulated by the hook regardless of the rotation angle of the adjustment plate. In order to facilitate the rotation of the adjustment plate, a plurality of notches are arranged on the upper circumference of the adjustment plate, which is convenient for holding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com