Direct-current gear motor

A technology of DC deceleration motor and machine base, which is applied in the direction of electrical components, electromechanical devices, electric components, etc. It can solve the problems of easy failure of parts, vibration of motor, and influence on the stability of motor, so as to prolong the service life and avoid loose installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

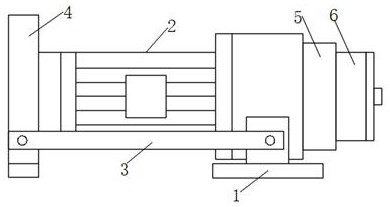

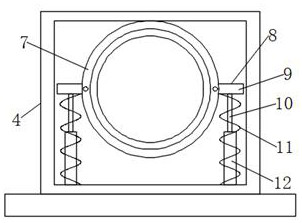

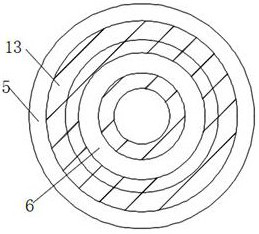

[0019] see Figure 1 to Figure 4 , the present invention provides a technical solution: a DC geared motor, including a machine base 1 and a machine body 2, a first outer ring 13 is provided on the surface of the machine body 2 opposite to the stable seat 4, and the outer surface of the first outer ring 13 is provided with There is a compression mechanism 14, the compression mechanism 14 includes a stable column 15, a second spring 16 and a moving column 17, the end of the moving column 17 away from the stable column 15 is provided with a moving ring 6, and the outside of the first outer ring 13 is provided with a second The outer ring 5 and the surface of the machine base 1 are symmetrically provided with a connecting plate 3, and a stabilizing seat 4 is provided between the ends of the two connecting plates 3 away from the machine base 1, the stabilizing seat 4 includes a vertical part and a horizontal part, and the stabilizing seat 4 The vertical part is provided with a roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com