Building construction plastic prefabricated part laying method

A technology of plastic prefabricated parts and a laying method, which is applied in construction, building construction, infrastructure engineering and other directions, can solve the problems affecting the overall appearance of the laying work surface, the deformation of plastic prefabricated parts, the error between the laying position and the designed laying position, etc. The effect of improving laying accuracy, improving work efficiency and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

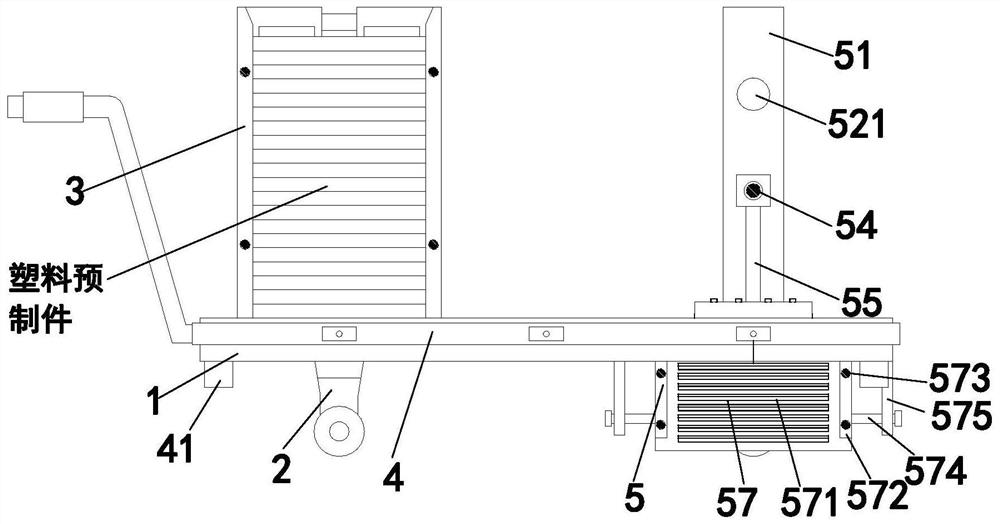

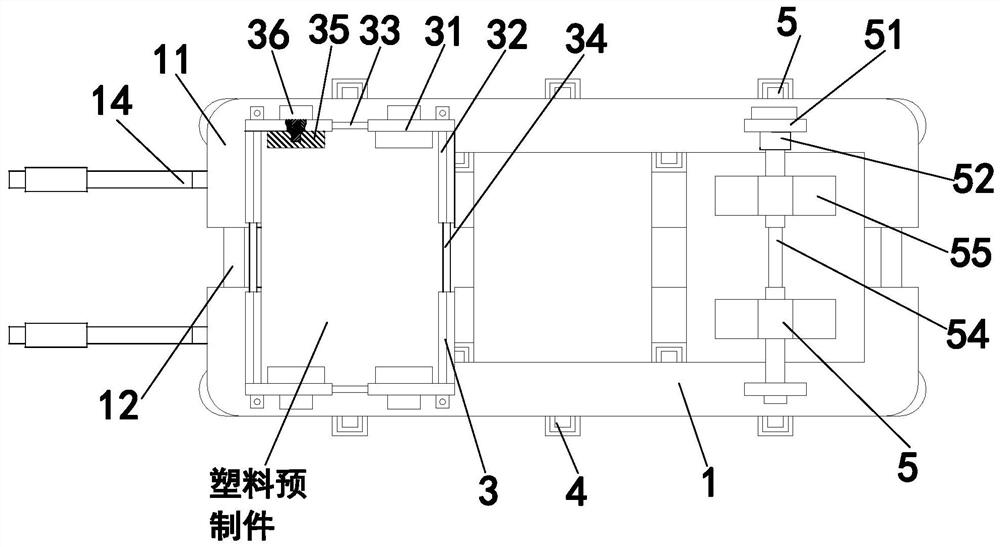

[0043] Such as Figure 1 to Figure 10 As shown, a method for laying plastic prefabricated parts for building construction uses a laying equipment, the laying equipment includes a base frame 1, a walking wheel 2, a material rack 3, a feeding device 4 and a laying device 5, and the above laying equipment The specific method for laying plastic prefabricated parts is as follows:

[0044] S1. Site cleaning: clean up the construction site to ensure the flatness of the construction ground;

[0045] S2. Cleaning of prefabricated parts: cleaning the surface of the prefabricated parts to be laid to remove the dust and mud attached to the surface of the prefabricated parts;

[0046] S3. Prefabricated parts are placed: the prefabricated parts processed throug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap