Detection device for detecting reasonable assembly torque of fastener

A technology for detection devices and fasteners, which is used to measure torque/torsion force and other directions during tightening, which can solve the problems of fan blade wear and reduce service life, and achieve the effect of accurate torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

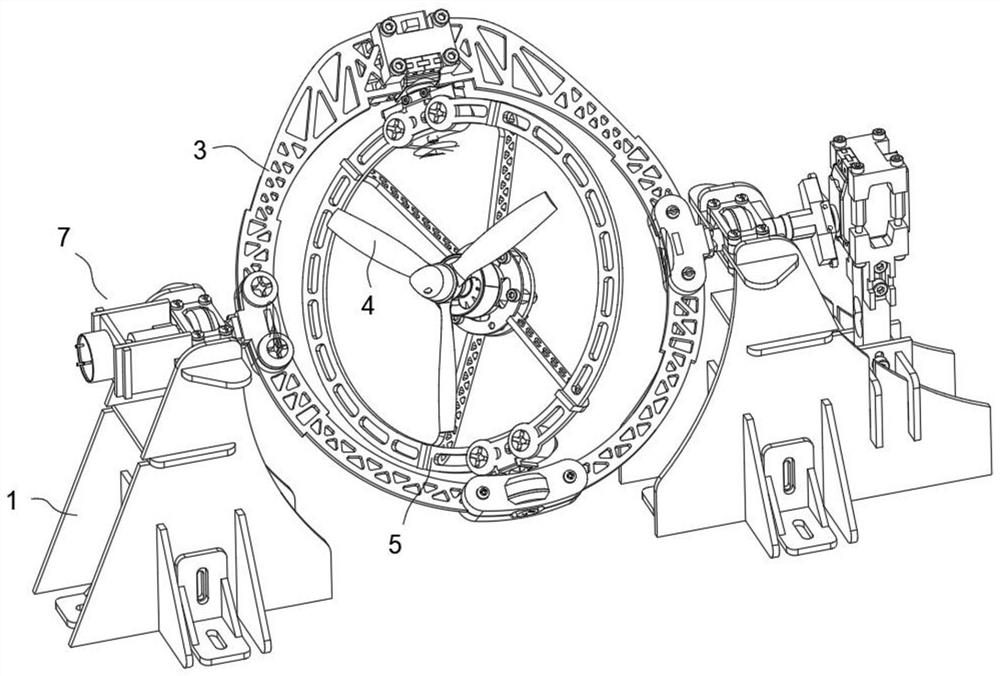

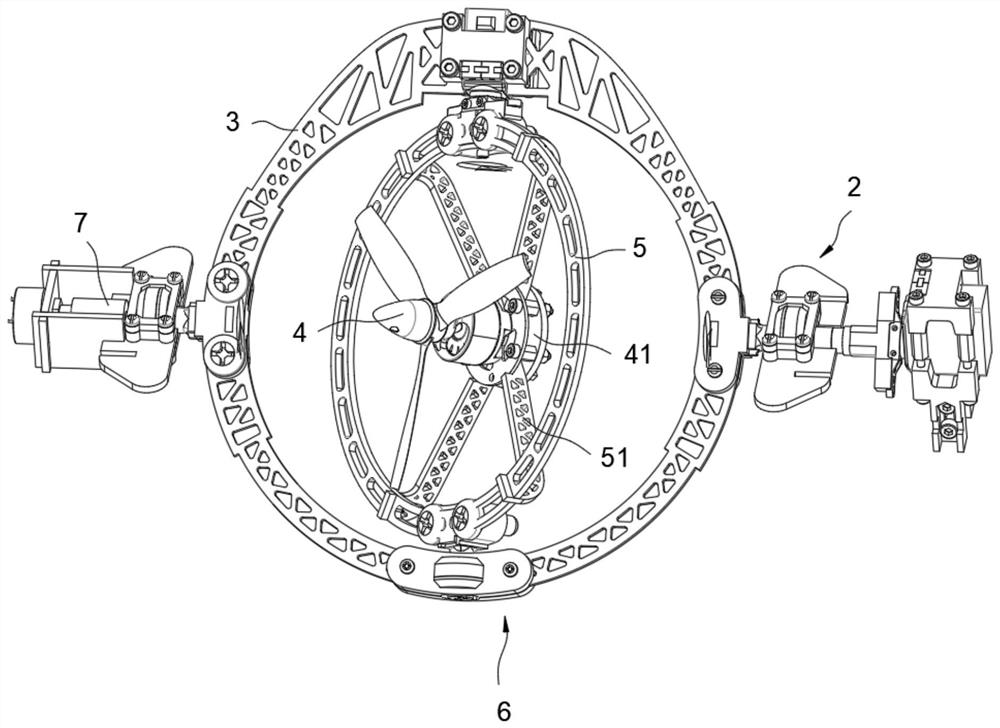

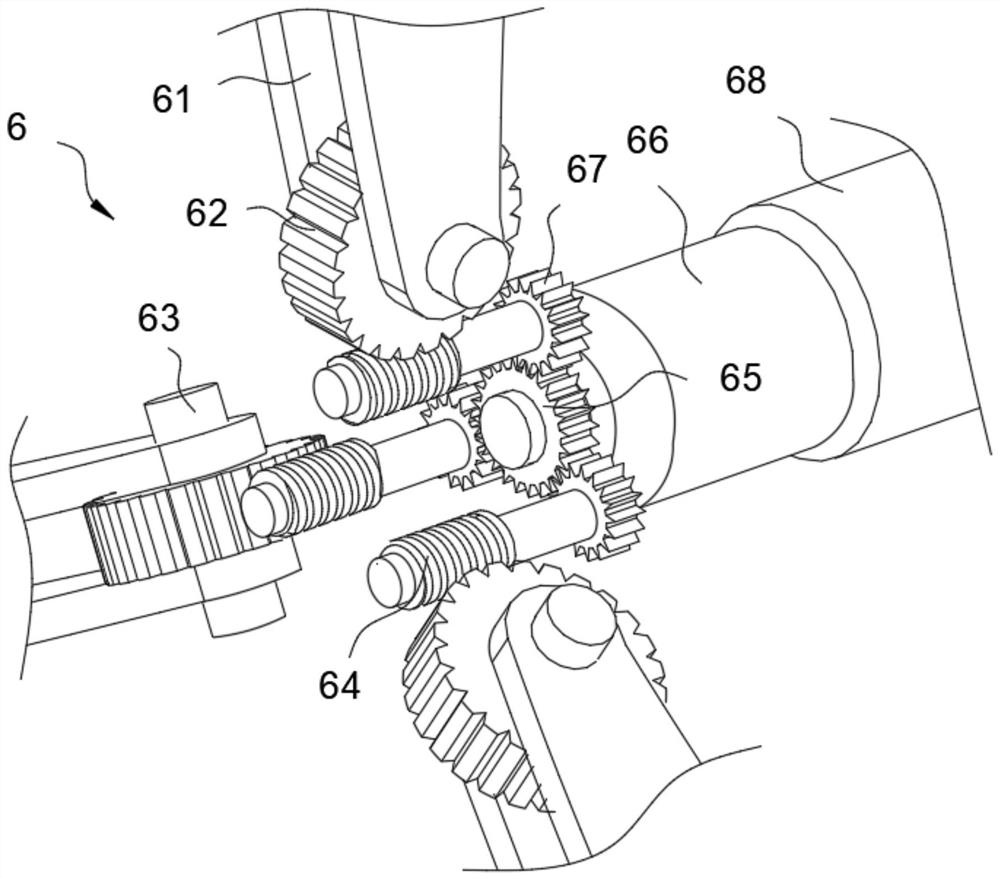

[0037] Example: When using the torque detection device, when the propeller 4 rotates, the torque detector 41 detects the torque of its rotation. Since the rotation directions of the outer ring body 3 and the inner ring body 5 are different and perpendicular to each other, at this time The propeller 4 can be rotated to the most suitable wind direction, so as to measure the torque more accurately; when the lubricating distribution device 7 is used, the gaseous lubricating oil is first introduced into the upper plate body 71, and the gaseous lubricating oil is passed through the gaseous lubricating oil nozzle. 72 is sprayed down, and the gaseous lubricating oil lubricates the rotation of the inner ring body 5 and the outer ring body 3, so that the friction between the two is reduced, so that the propeller 4 can accurately face the current wind direction; When sealing, the film roller 21 is rotated to make the sealing film 22 stick to the plate, the excess sealing film 22 is recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com