Circulating concrete material and component impact tester and using method

An impact tester and concrete technology, which is applied in the direction of applying repetitive force/pulse force to test the strength of materials, etc., can solve the problems that the test cycle needs manual control, cannot meet the diversification of tests, and the cost of equipment is high, so as to shorten the test cycle, Destruction phenomenon is real and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

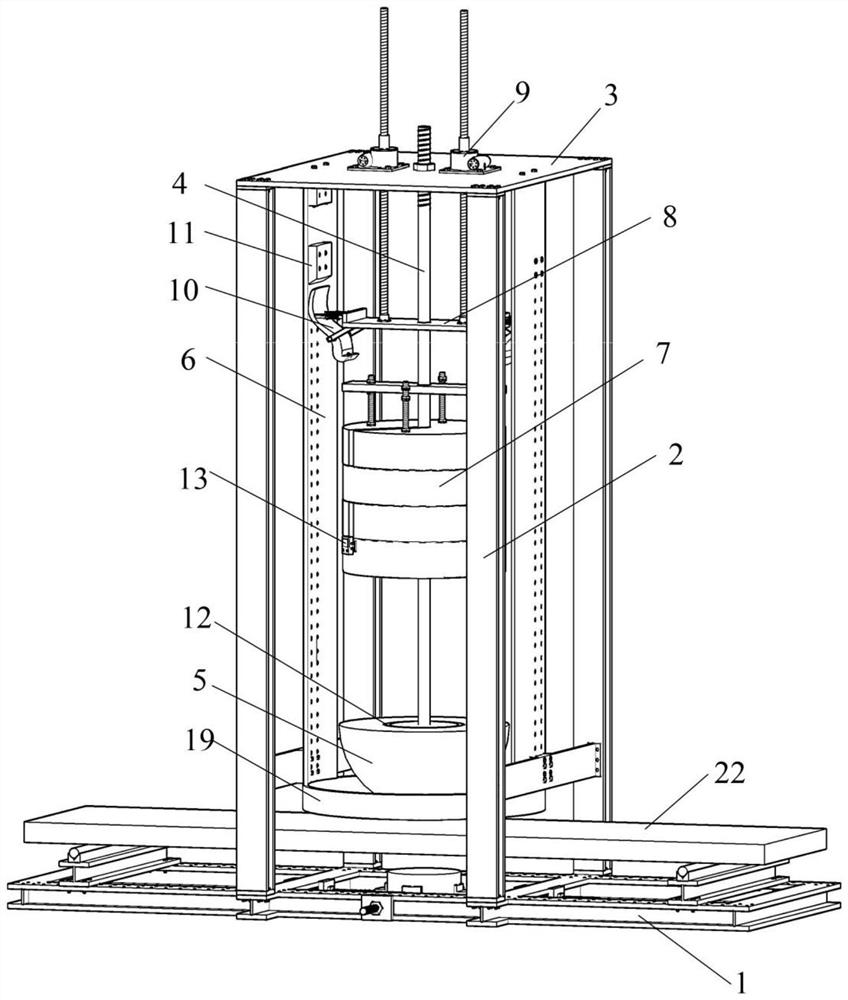

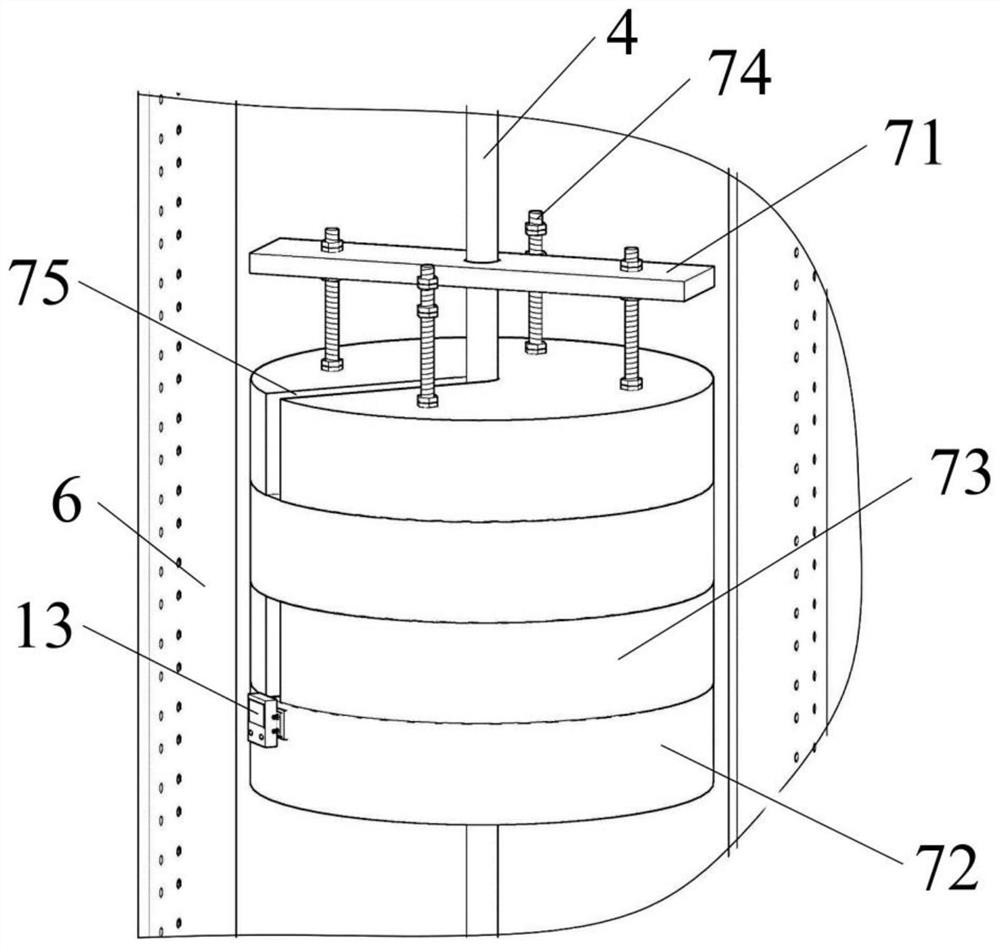

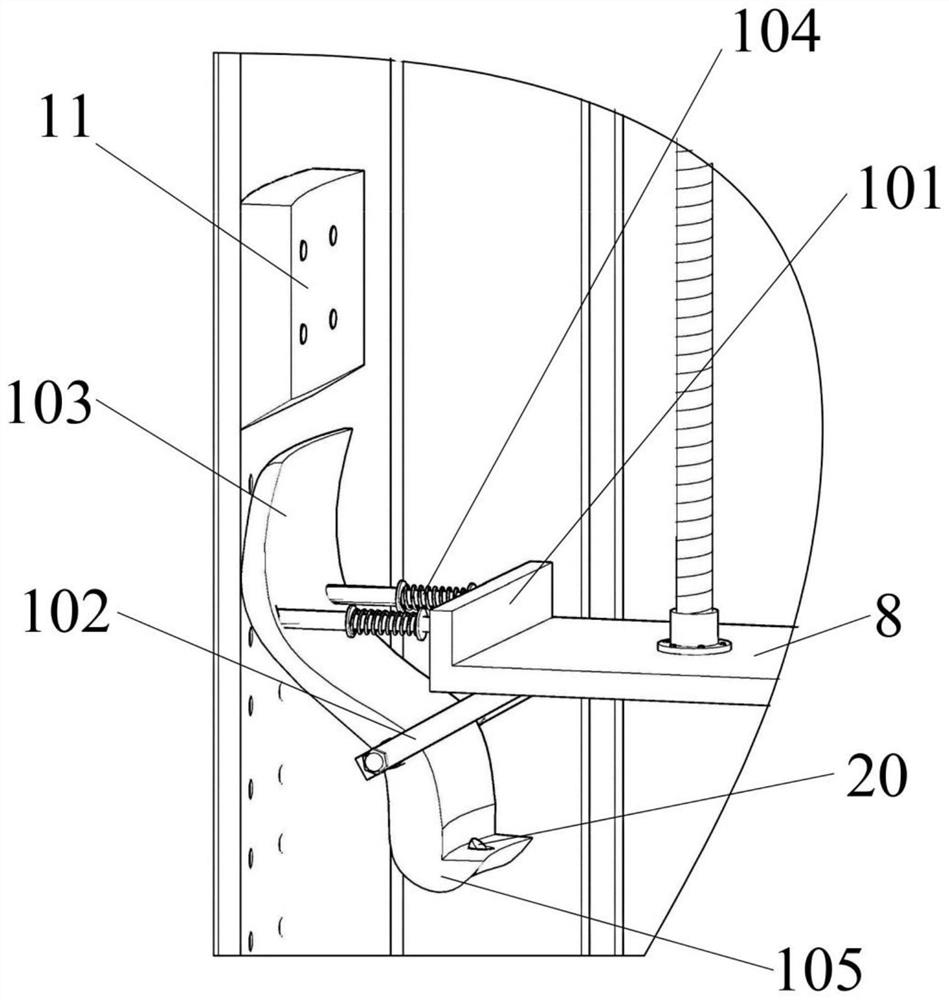

[0032] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0033] Such as Figure 1-Figure 5 , a circular concrete material and component impact tester, comprising a base 1, the base 1 is connected to a top plate 3 through a bracket 2, the middle bolt of the bottom plate 3 is connected to a hammer rod 4, and the lower end of the hammer rod 4 is fixedly connected to a hammer 5, An embedded magnetic coil 12 is arranged in the hammer.

[0034] The brackets 2 on both sides of the hammer 5 are symmetrically provided with drop distance limiting plates 6 , and the bottom ends of the two fall distance limiting plates 6 are fixedly connected with a fixed ring 19 .

[0035] The lower part of the hammer rod 4 is slidably connected to the loading weight plate 7, and the upper part of the hammer rod 4 is slidably connected to the lifting platform 8, which is driven by the screw lifting mechanism 9, and the two sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com