A device for restoring the mechanical properties of wire insulation

A wire insulation and mechanical performance technology, applied in the direction of cable suspension, cable installation, overhead installation, etc., can solve the problems of potential safety hazards and loss of mechanical properties of the wire insulation layer, and achieve simple structure, high safety factor, The effect of restoring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

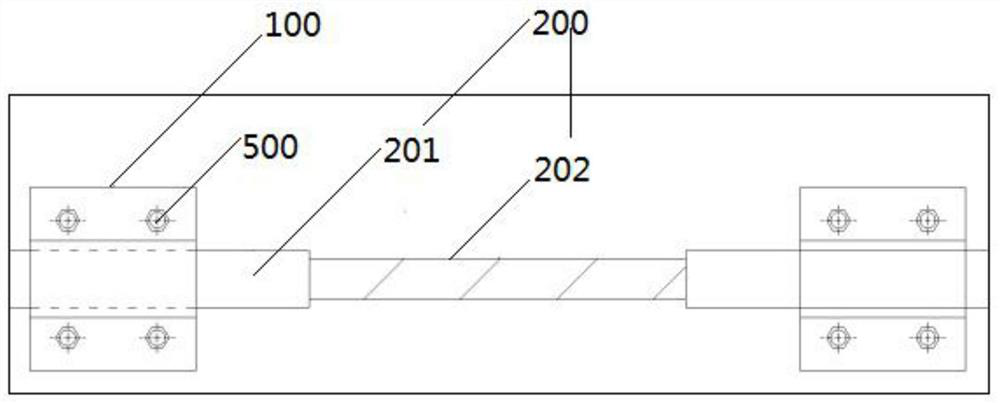

[0040] see figure 1 , is a structural schematic diagram of the fixed terminal assembly of the present application installed on the wire.

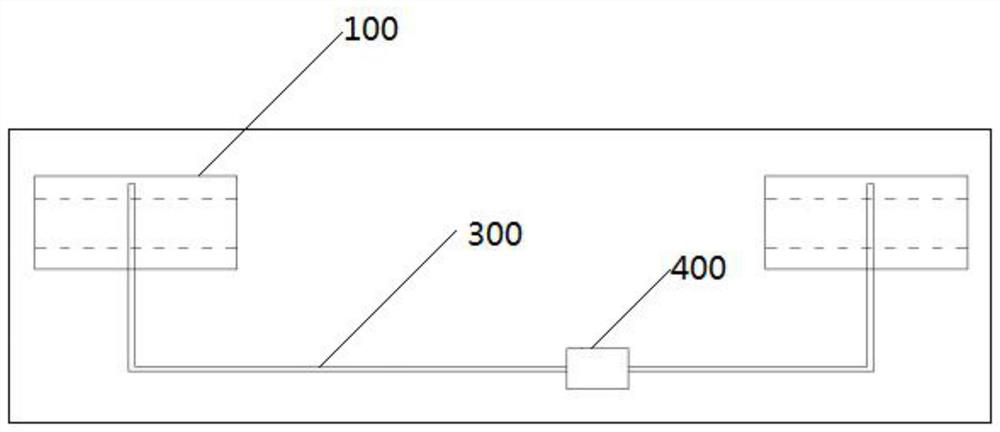

[0041] Such as figure 1 and image 3 As shown, the application provides a device for restoring the mechanical properties of the wire insulation layer, the device comprising:

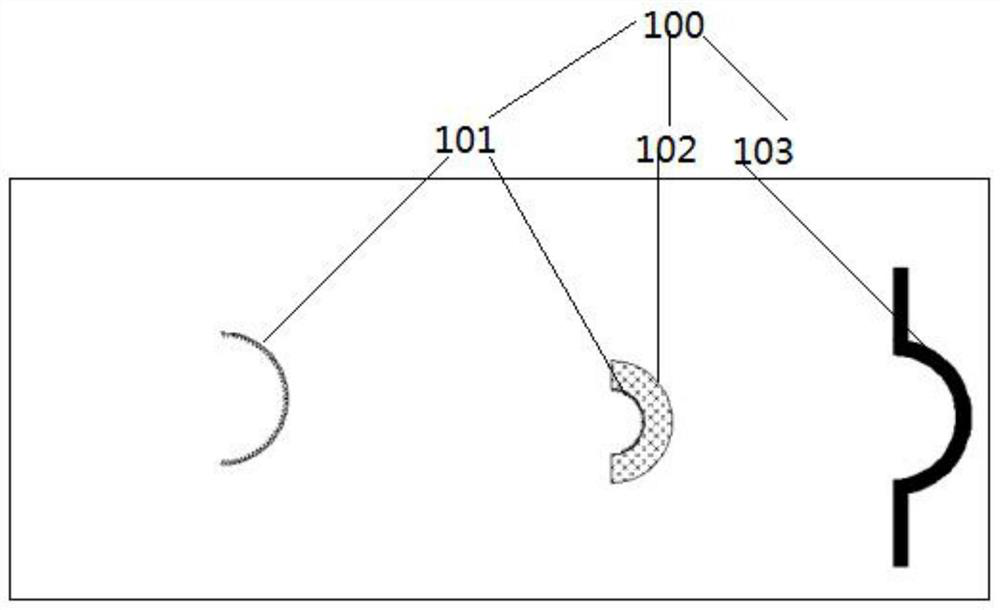

[0042] A fixed terminal assembly 100, the fixed terminal assembly 100 is arranged at the boundary of the wire 200 whose insulation layer has been stripped and extends outward for a certain distance;

[0043] A connecting part 300, the connecting part 300 is connected to the fixed terminal 103 assembly;

[0044] The load cell 400 is installed on the connection part 300 and connected in series with the connection part 300 .

[0045] In the above technical solution, when the wire core 202 whose insulation layer has been stripped is subjected to tension, a certain friction force will be generated between the combination of the two fixed terminal assemblies 100 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com