Conveying device for rice processing

A conveying device and rice processing technology, applied in the field of rice processing, can solve problems such as inability to effectively remove rice impurities and affect the quality of rice products, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

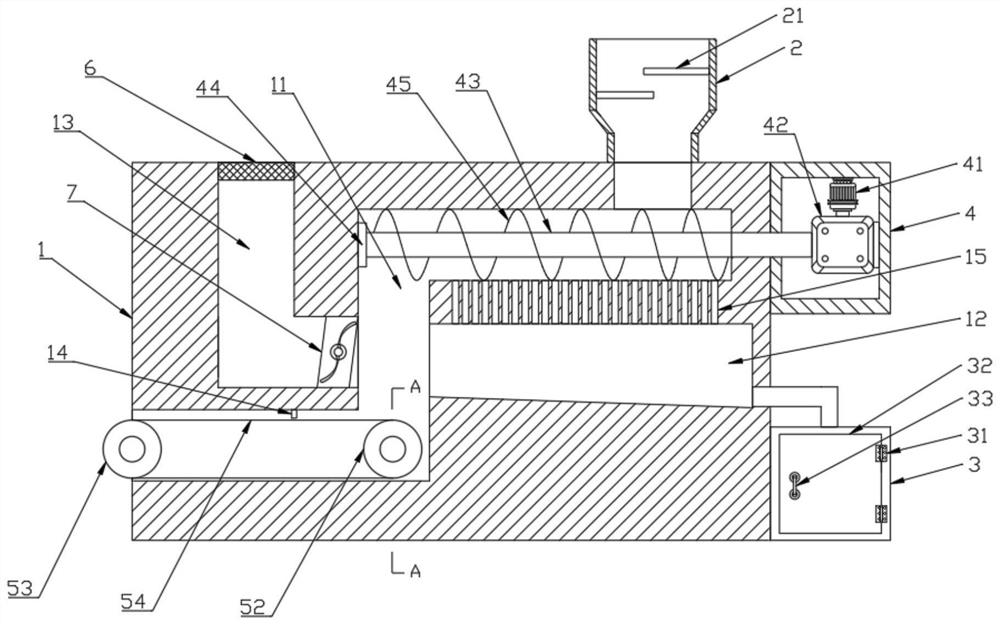

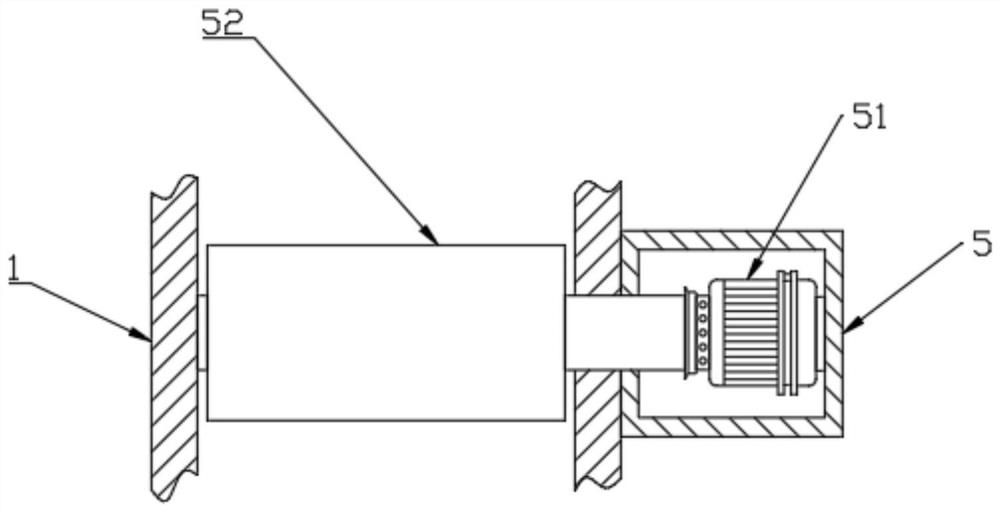

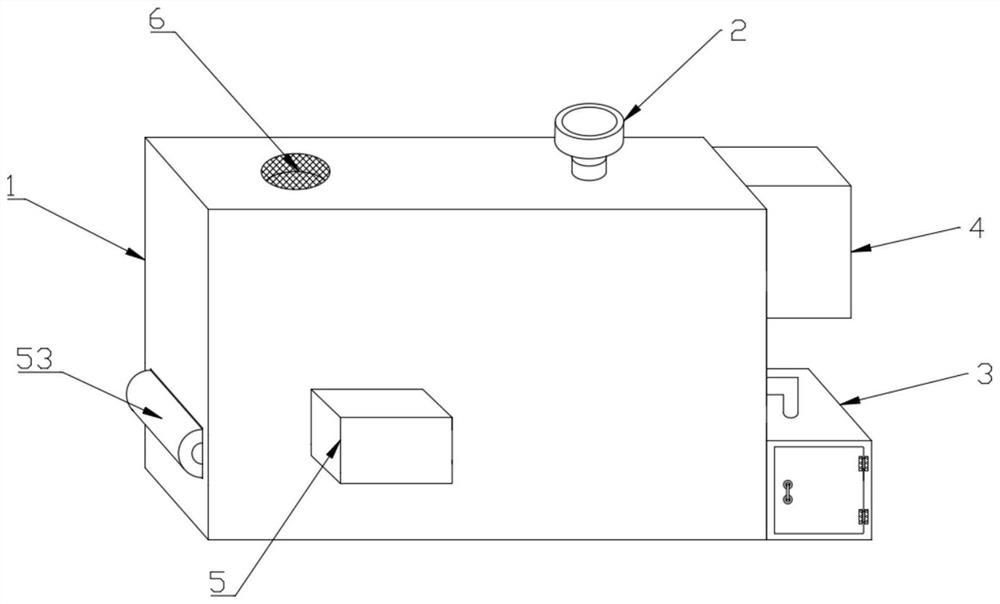

[0024] see Figure 1-3 , a conveying device for rice processing, comprising a body 1, a feeding funnel 2, a waste box 3, a first protective box 4 and a second protective box 5, the right side of the top surface of the body 1 is provided with a feeding port, and the The feeding funnel 2 is fixedly connected to the feed inlet, the left side of the body 1 is provided with a discharge port, the right side of the body 1 is provided with a waste outlet, and the bottom of the right side wall of the body 1 is fixedly connected with the Waste box 3, the top of the waste box 3 communicates with the waste outlet through a feed pipe, the inside of the body 1 is provided with a rice delivery chamber 11, the rice delivery chamber 11 is stepped, and the rice delivery chamber 11 The upper end communicates with the feed inlet, and the left end of the rice conveying chamber 11 communicates with the discharge outlet; the top of the outer wall of the right side plate of the body 1 is fixedly conn...

Embodiment 2

[0032] This embodiment is a further improvement made on the basis of Embodiment 1, specifically as follows:

[0033] see Figure 1-3 , the top surface of the body 1 is provided with a vent 13, and the lower port of the vent 13 communicates with the vertical chamber of the rice conveying chamber 11.

[0034] The upper port of the vent 13 is fixedly equipped with a ventilation net cover 6; Port, in the process of rice falling from the vertical cavity, by setting the fan 7, the empty rice husks, small broken leaves, broken grass, etc. entrained in the rice are effectively blown into the waste conveying channel 12, and then the rice is further processed. Impurity removal ensures the quality of rice.

[0035] The last few points should be explained: First, in the description of this application, it should be explained that, unless otherwise specified and limited, the terms "installation", "connection" and "connection" should be understood in a broad sense, which can be mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com