Cutter grinding device

A tool and sliding installation technology, applied in grinding drive devices, manufacturing tools, grinding workpiece supports, etc., can solve problems such as inability to use different grinding methods, inability to adjust the height of the tool, and the inability of the blade to face grinding, etc., to achieve a stable fixation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

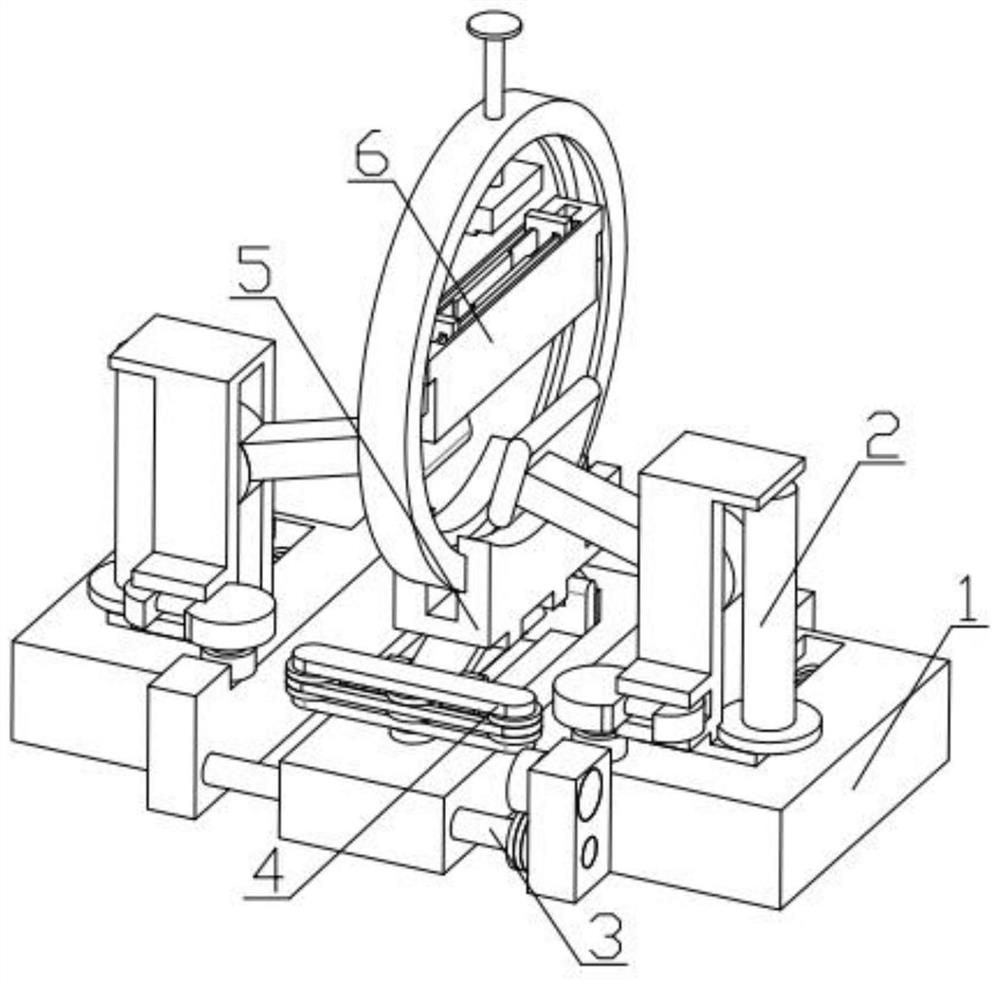

[0036] Combine below Figure 1-11Describe this embodiment, a tool grinding device, including a toggle and base 1, a grinding adjustment mechanism 2, a position adjustment mechanism 3, a one-way power mechanism 4, an angle adjustment mechanism 5 and a tool fixing mechanism 6, the grinding adjustment mechanism 2 Slidingly installed in the groove provided on the toggle and base 1, the two sides of the position adjustment mechanism 3 are respectively fixedly installed with the toggle and base 1, the one-way power mechanism 4 is fixedly installed on the position adjustment mechanism 3, and the angle adjustment mechanism 5 is fixedly installed on the position adjustment mechanism 3, and the tool fixing mechanism 6 is fixedly installed on the angle adjustment mechanism 5.

specific Embodiment approach 2

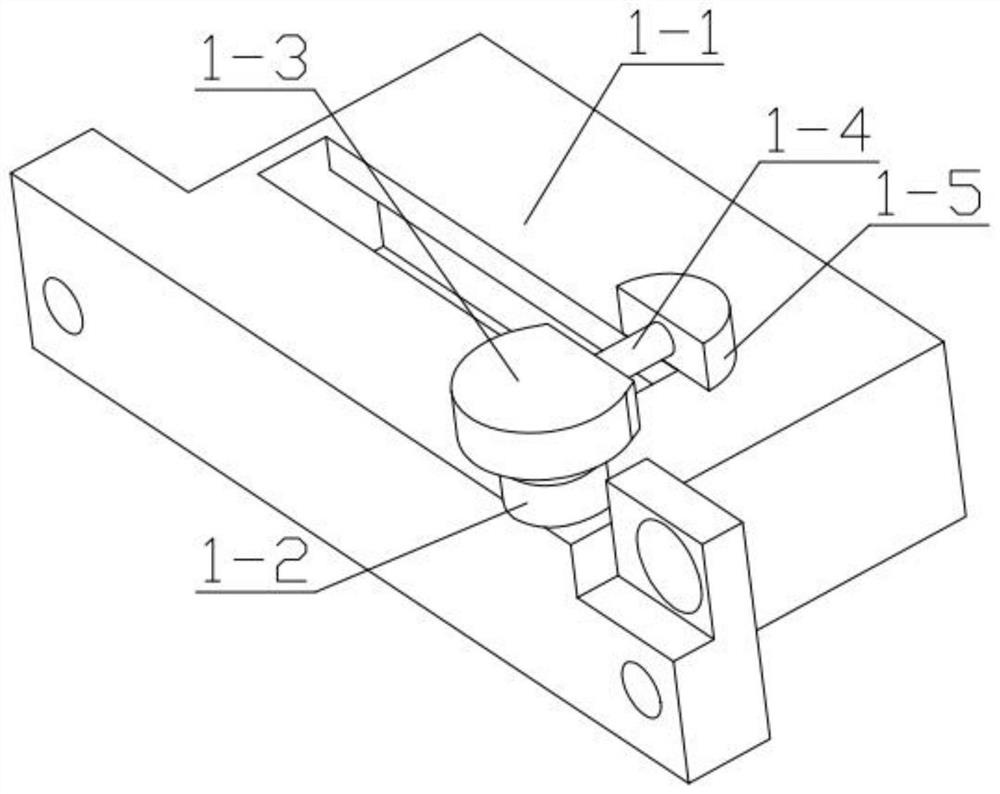

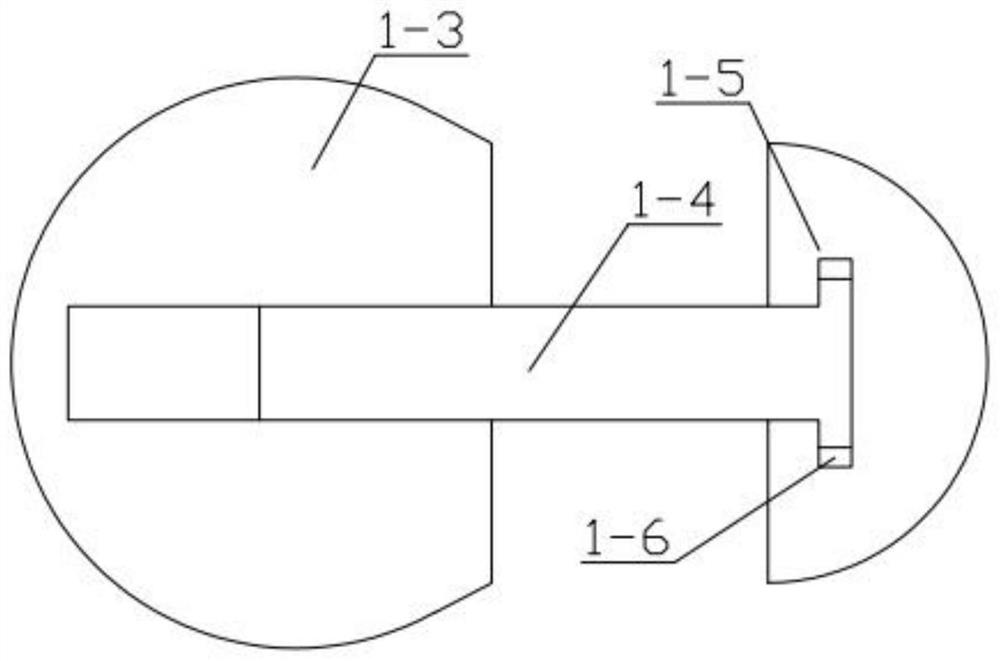

[0038] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the toggle and base 1 includes a base 1-1, a bottom gear 1-2, a cam connector 1-3, an adjustment threaded rod 1-4, a semicircle Pieces 1-5, rubber ring 1-6, the bottom gear 1-2 is rotatably installed in the groove provided on the base 1-1, the cam connector 1-3 is fixedly installed on the bottom gear 1-2, adjust the threaded rod 1 -4 is threadedly connected with the cam connector 1-3, the other end of the adjusting threaded rod 1-4 is rotatably mounted on the adjusting threaded rod 1-4, and the rubber ring 1-6 is fixedly mounted on the adjusting threaded rod 1-4.

specific Embodiment approach 3

[0040] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the grinding adjustment mechanism 2 includes a support spring 2-1, a stand 2-2, a manual turntable 2-3, a worm 2-4, a worm wheel 2- 5. The connecting rod 2-6, the grinding stone 2-7, the stand 2-2 is slidably installed in the groove provided on the base 1-1, and one end of the support spring 2-1 is fixedly installed on the stand 2-2, The other end of the support spring 2-1 is fixedly installed on the base 1-1, the manual turntable 2-3 is rotatably installed in the groove provided on the stand 2-2, the manual turntable 2-3 is fixedly connected with the worm screw 2-4, The other end of the worm 2-4 is rotatably installed in the groove provided on the stand 2-2, the worm 2-4 is meshed with the worm wheel 2-5, and the worm wheel 2-5 is rotatably installed in the recess provided on the stand 2-2. In the groove, the worm gear 2-5 is fixedly connected with the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com