Patents

Literature

31results about How to "Realize the function of grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

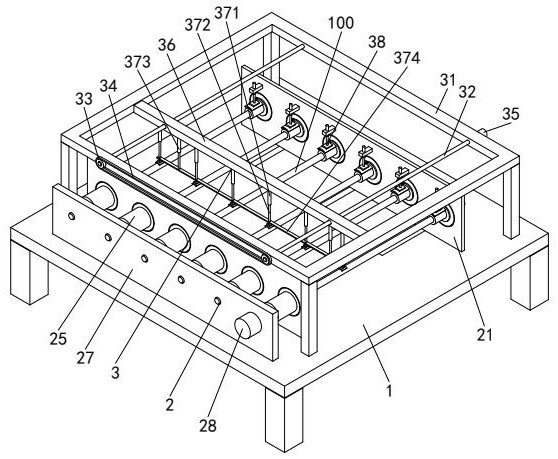

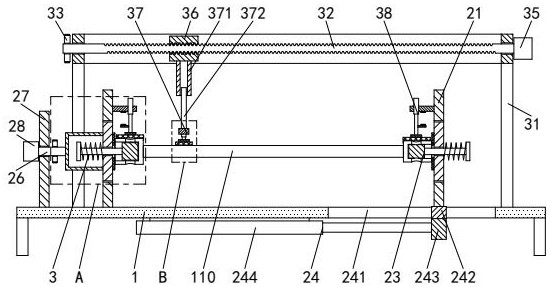

Numerical control equipment

InactiveCN102699769ASimple structureGood bearing effectFeeding apparatusLarge fixed membersEngineeringClosed loop

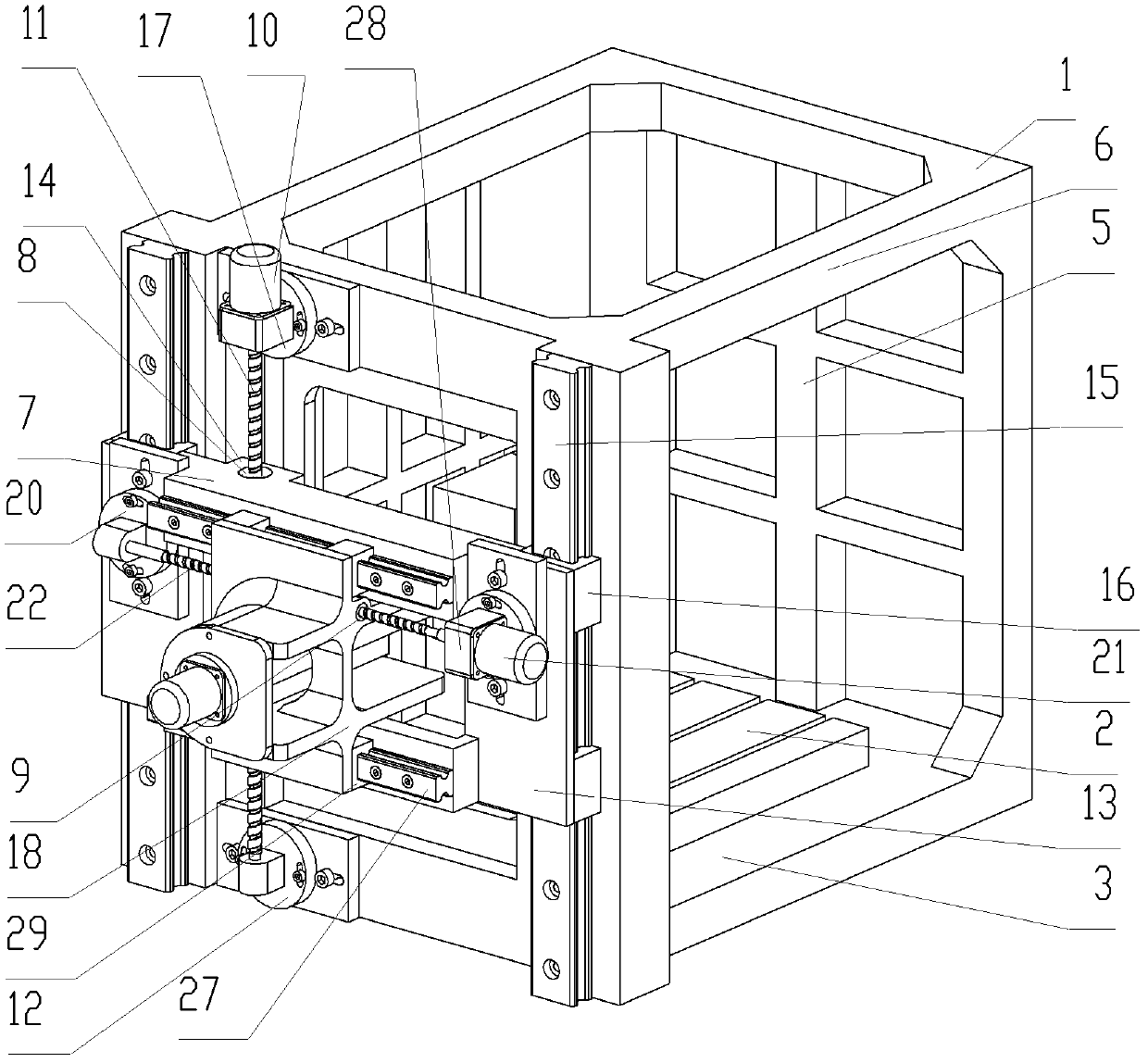

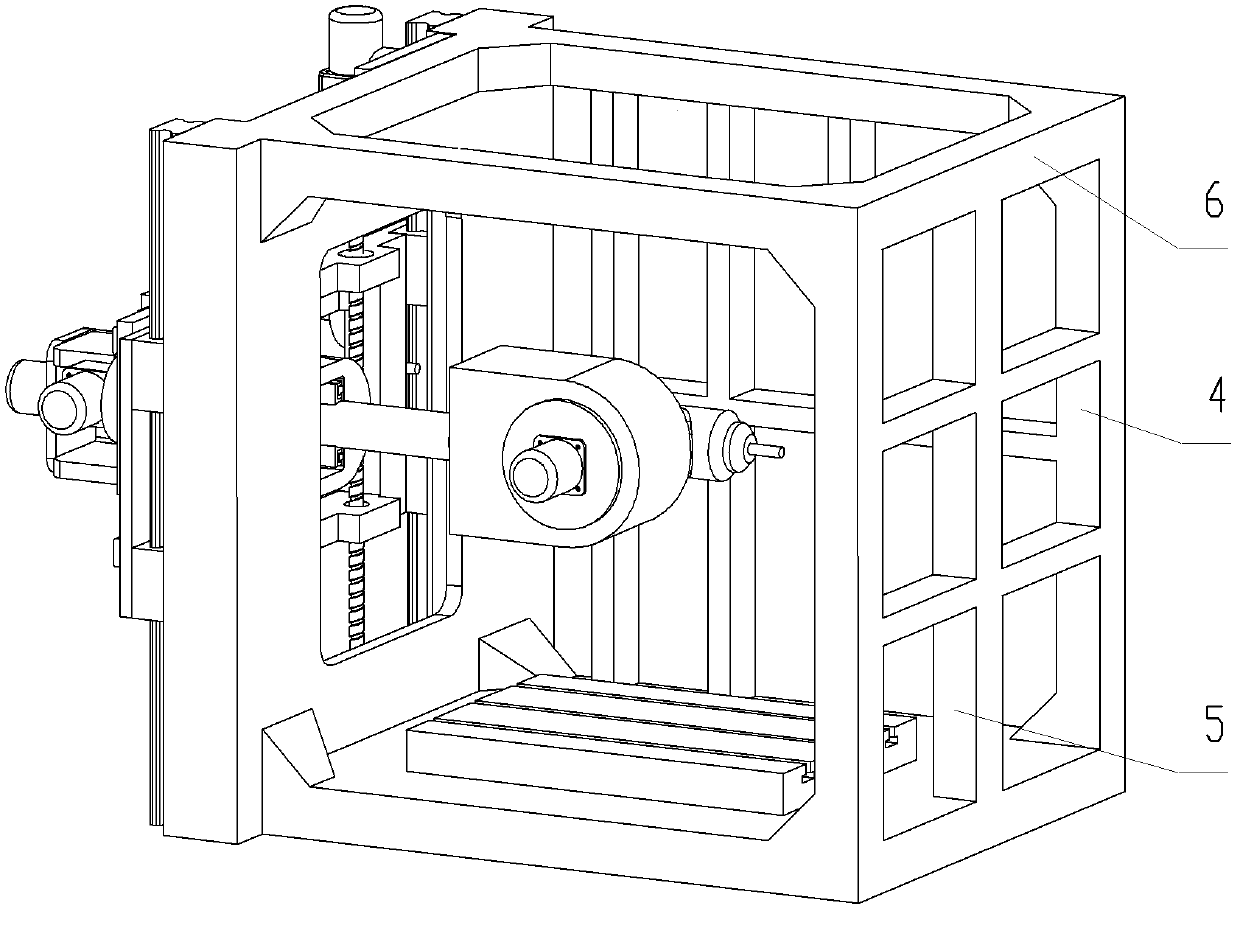

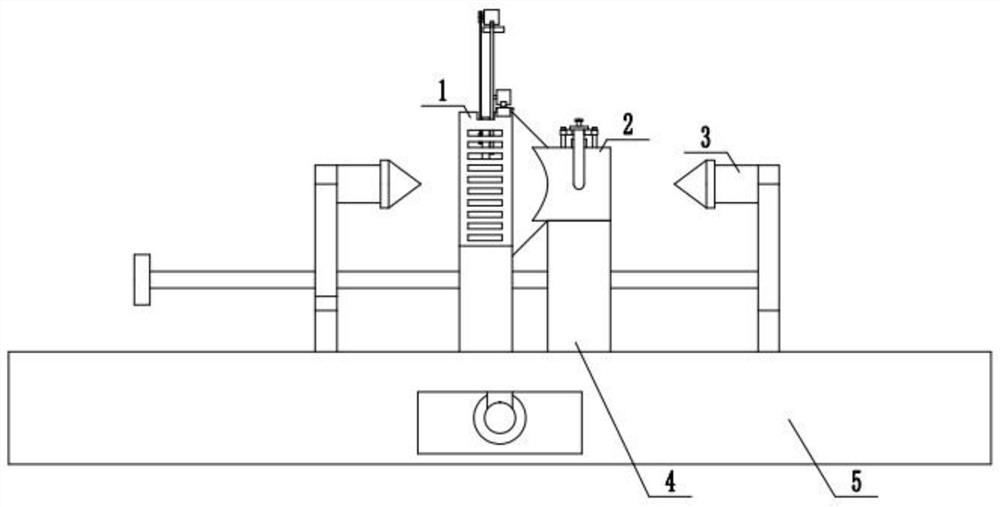

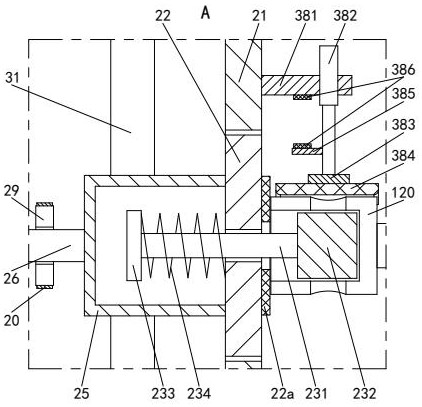

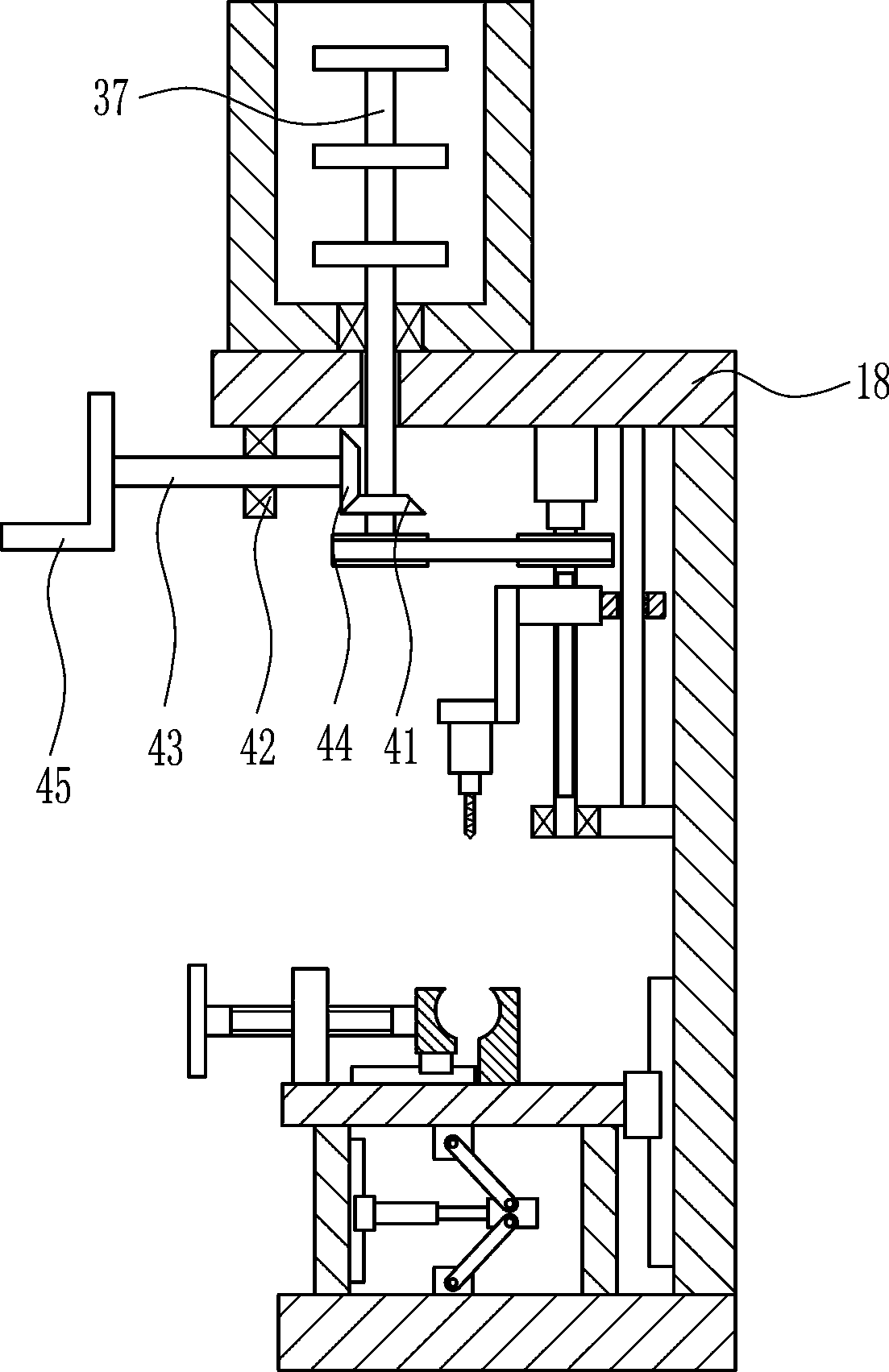

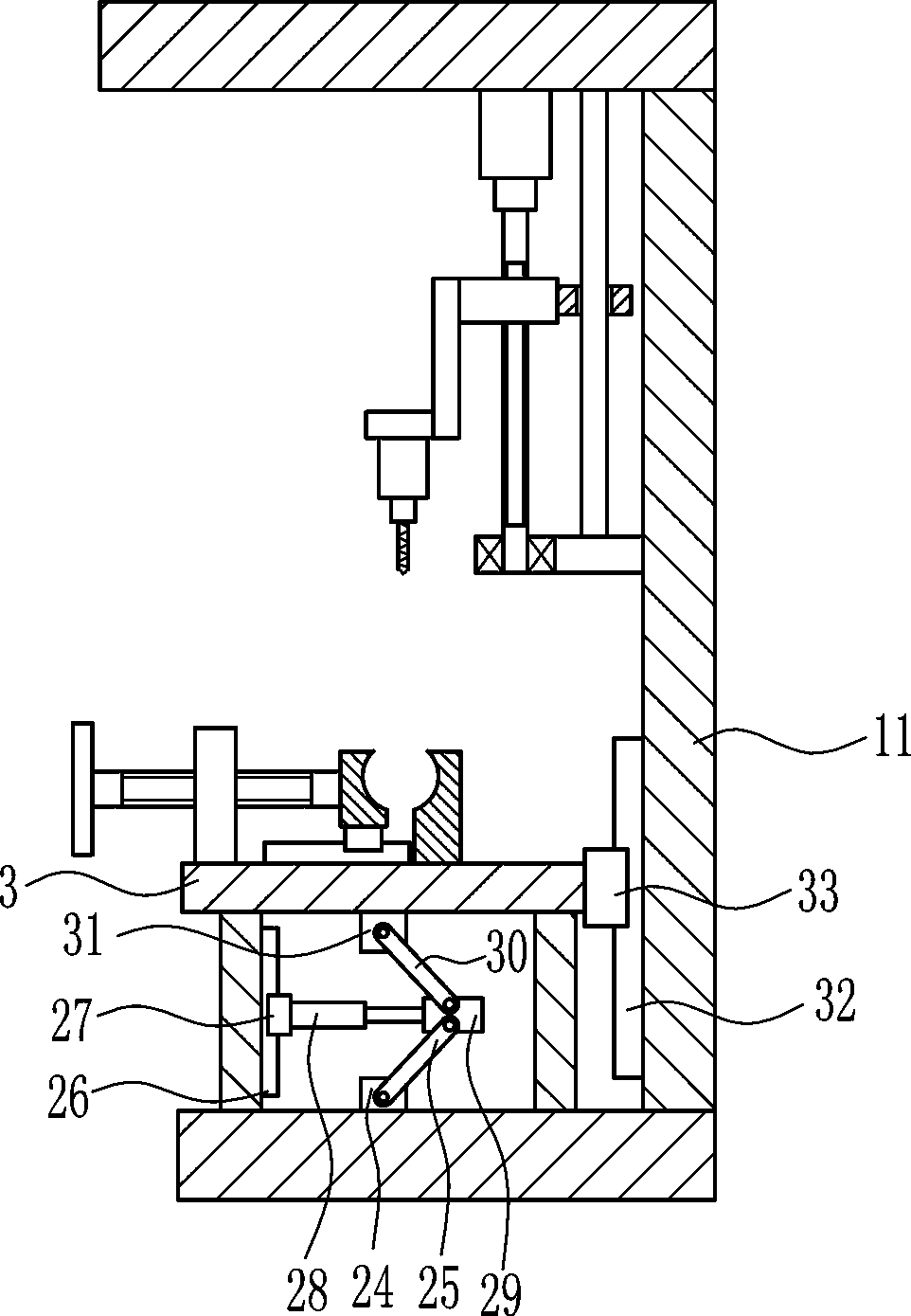

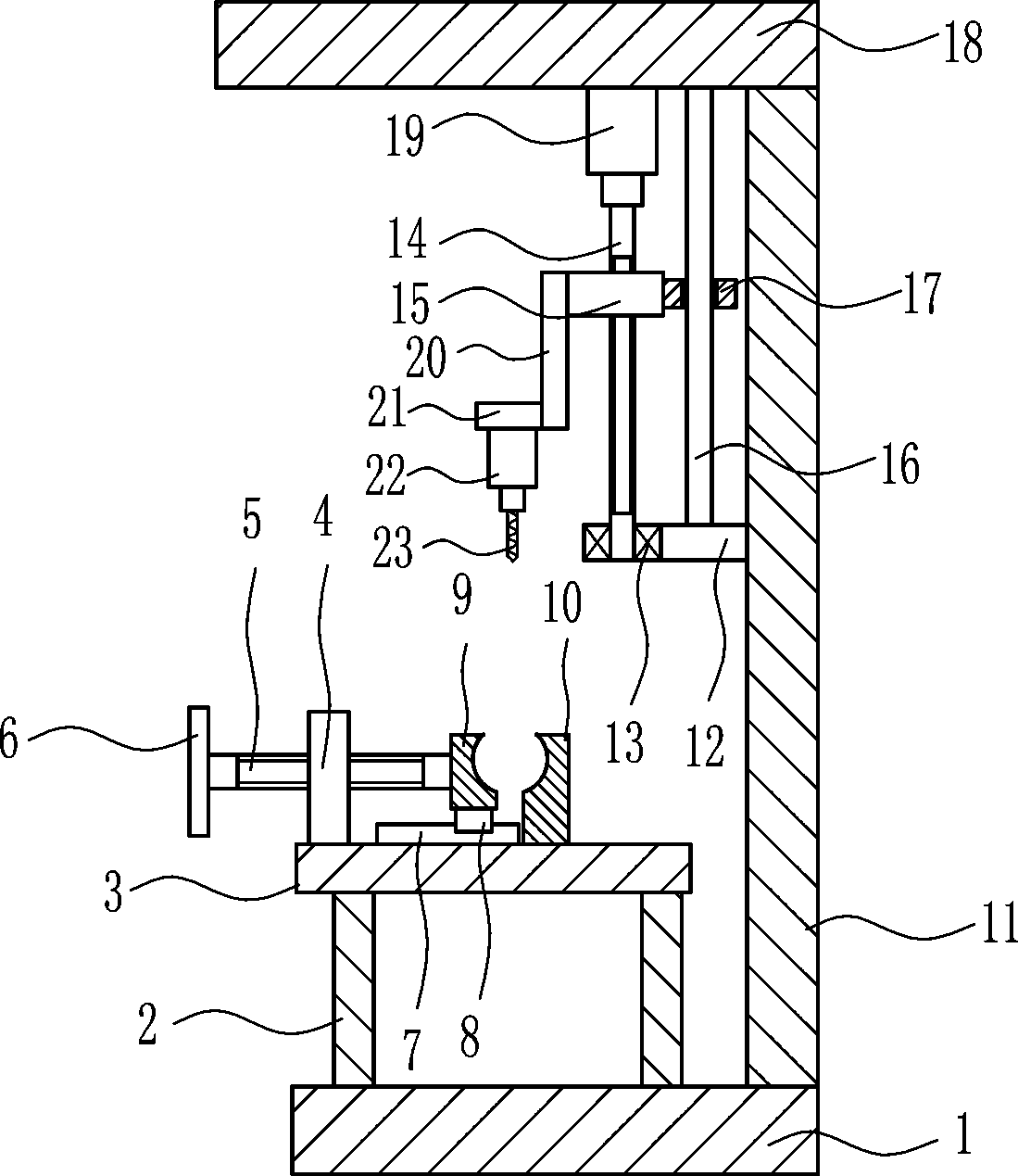

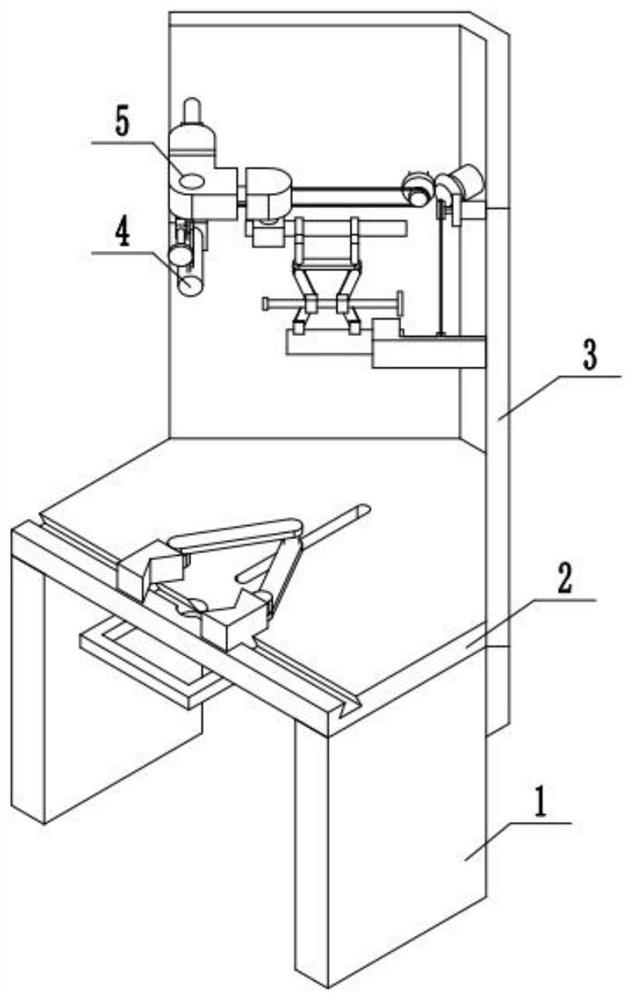

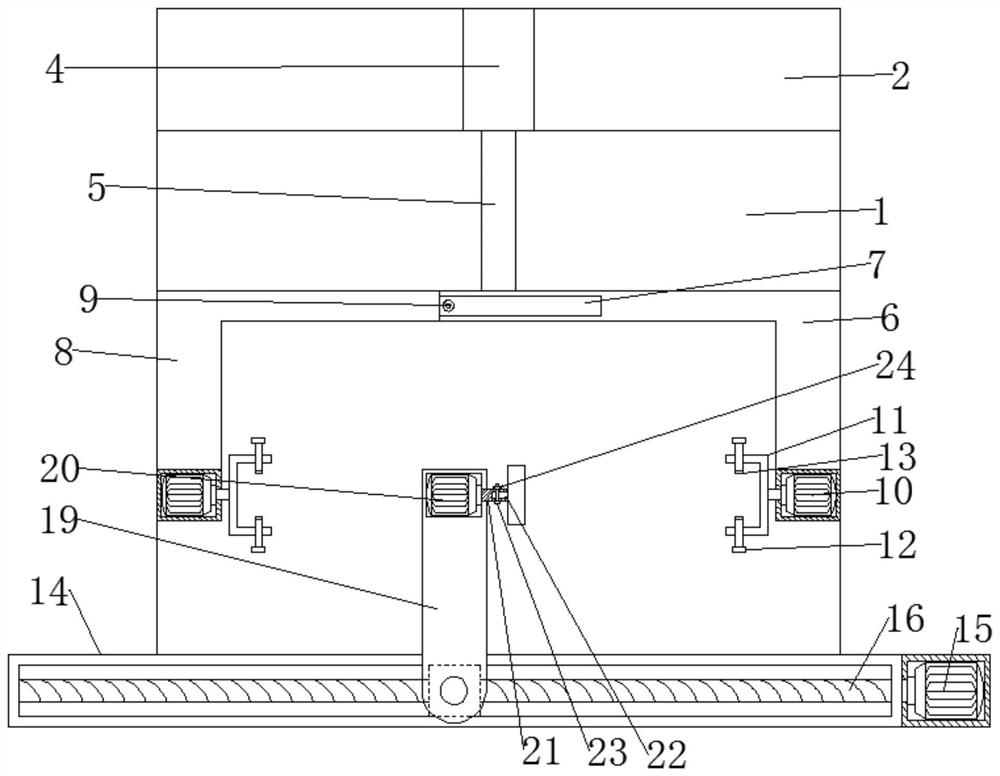

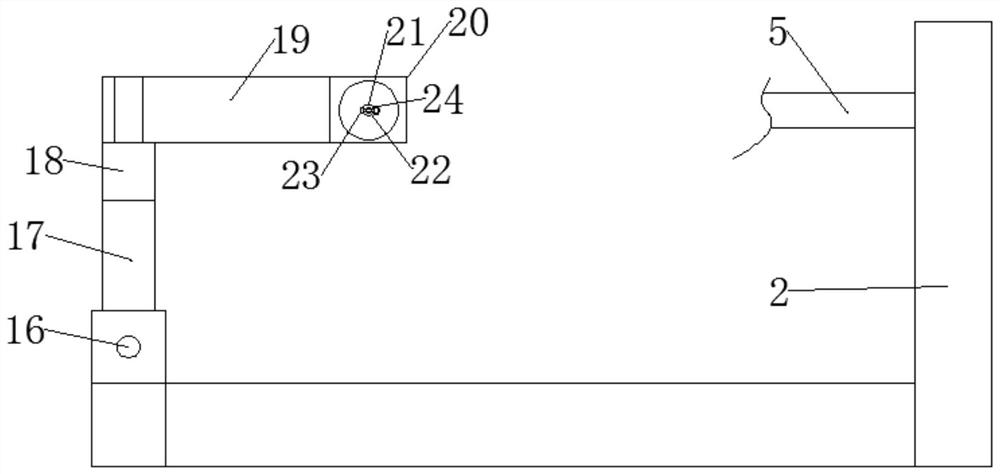

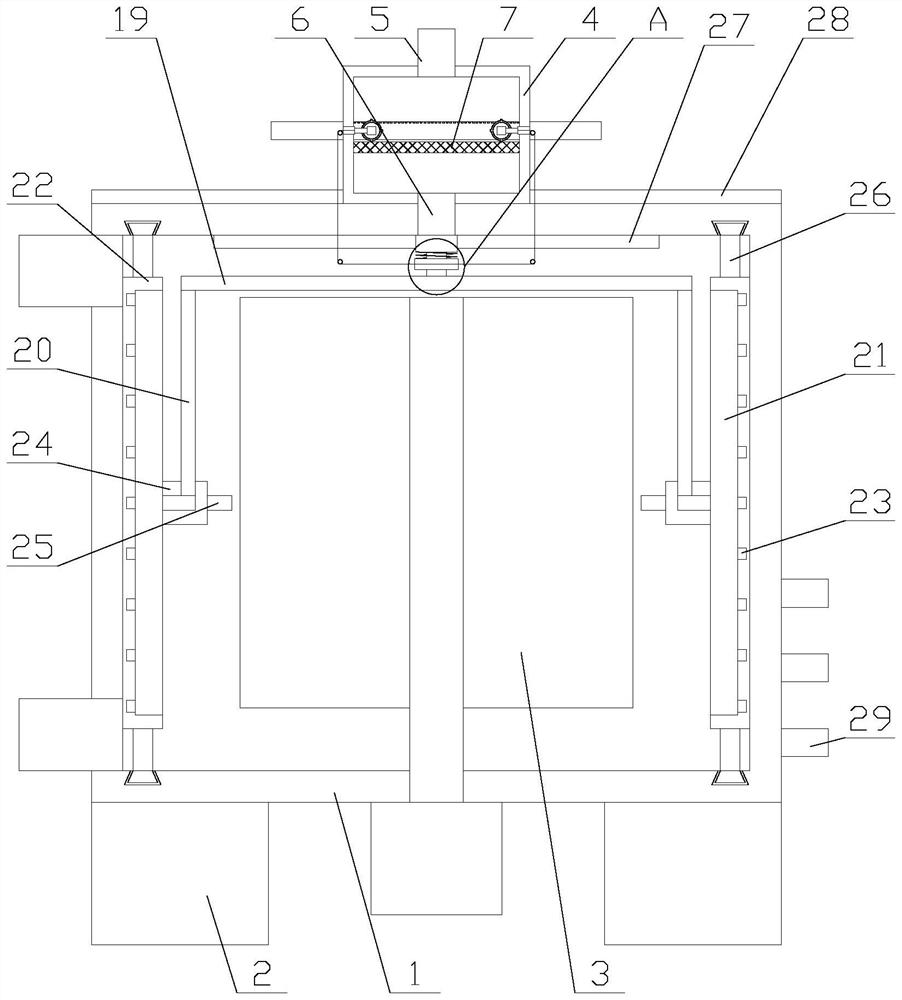

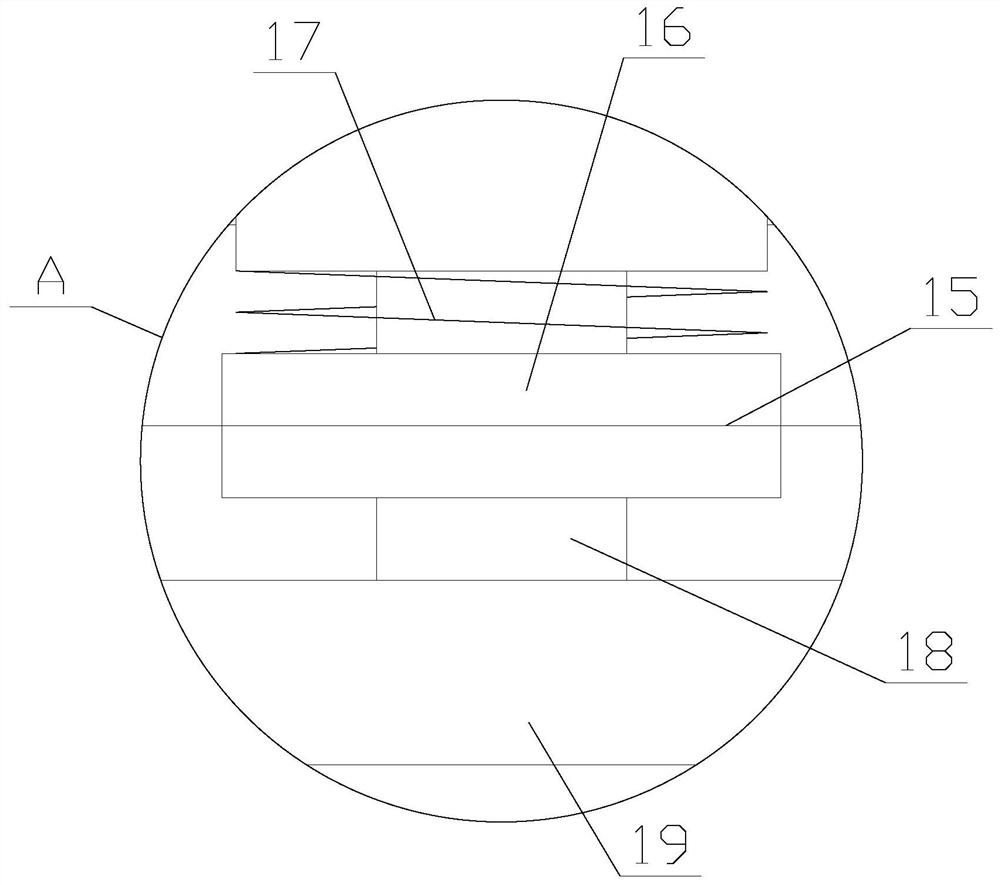

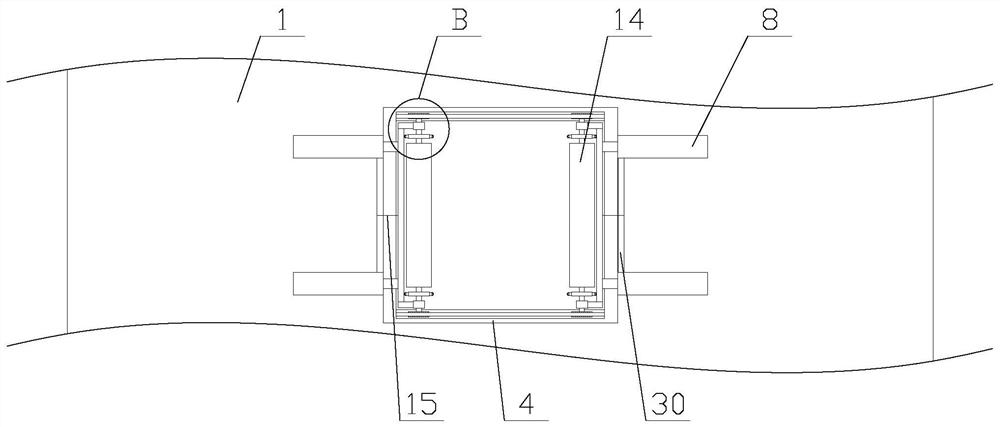

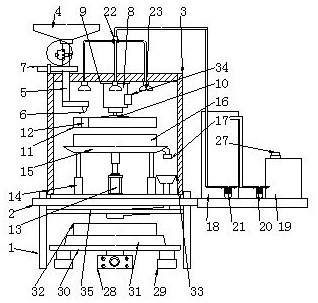

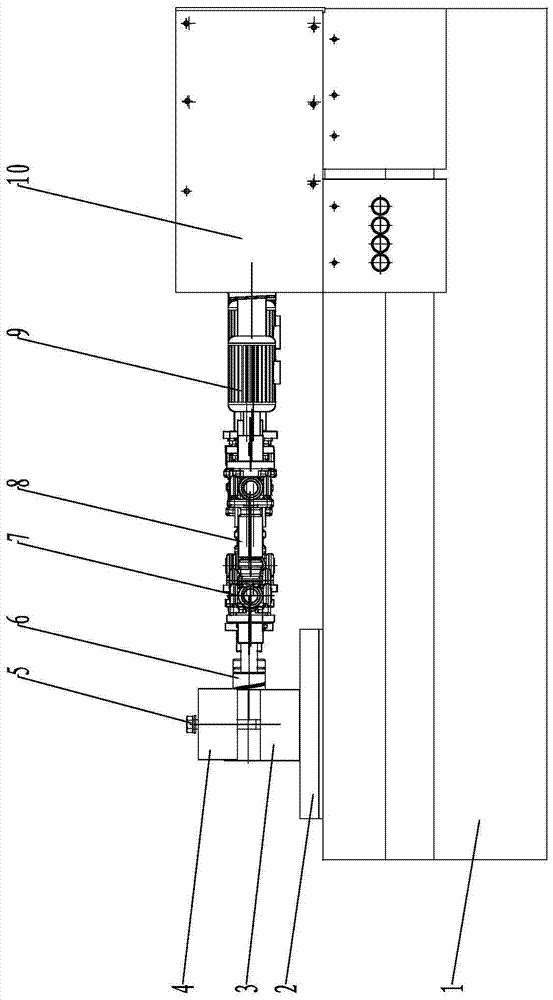

Numerical control equipment comprises a main body framework and a workpiece clamping device. The main body framework comprises a base, a first main supporting part and a second main supporting part, as well as a first connecting part and a second connecting part, wherein the first main supporting part and the second main supporting part are arranged on two opposite sides of the base. The first connecting part and the second connecting part are used for connecting two opposite sides of the first main supporting part and the second main supporting part together. The first main supporting part, the first connecting part, the second main supporting part and the second connecting part are connected end to end to form a closed loop structure, and a workpiece exit is arranged at the top of the closed loop structure. More than one of the left side, the right side and the rear side of the main body framework is provided with machining heads and machining head moving mechanisms enabling the machining heads to move along at least three axes. The left side, the right side and the rear side of the main body framework are respectively provided with machining heads, different machining heads can be selected as main machining heads on each lateral side, thus each lateral side of workpieces can be machined with three different power heads under the premises that power heads are not replaced and the workpieces are not clamped for the second time; the machining standard is consistent, the three power heads can work simultaneously, and the efficiency is high.

Owner:杨东佐

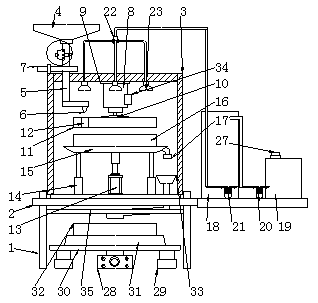

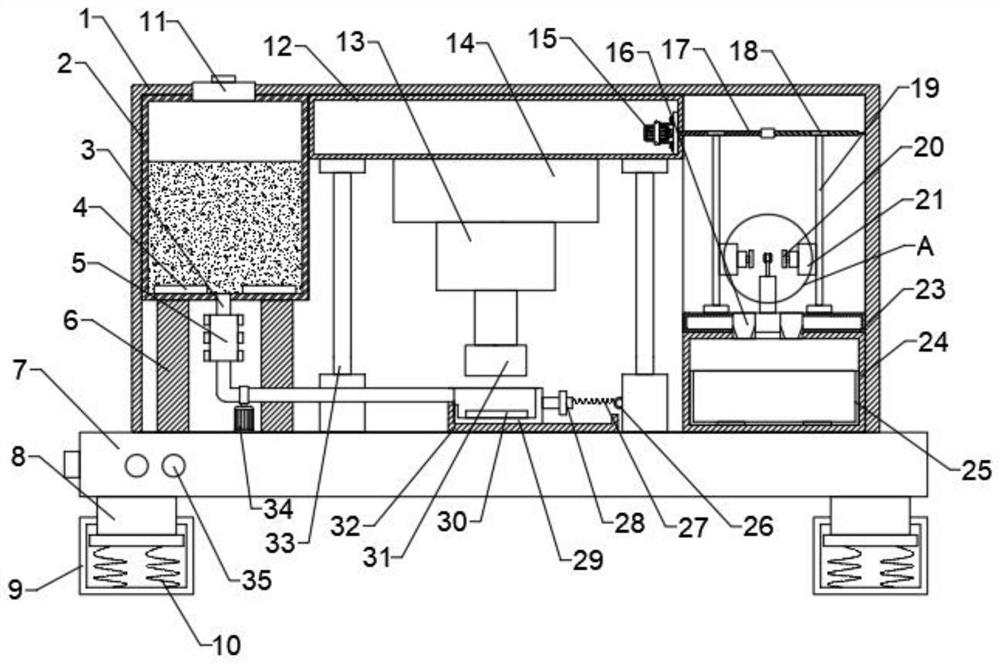

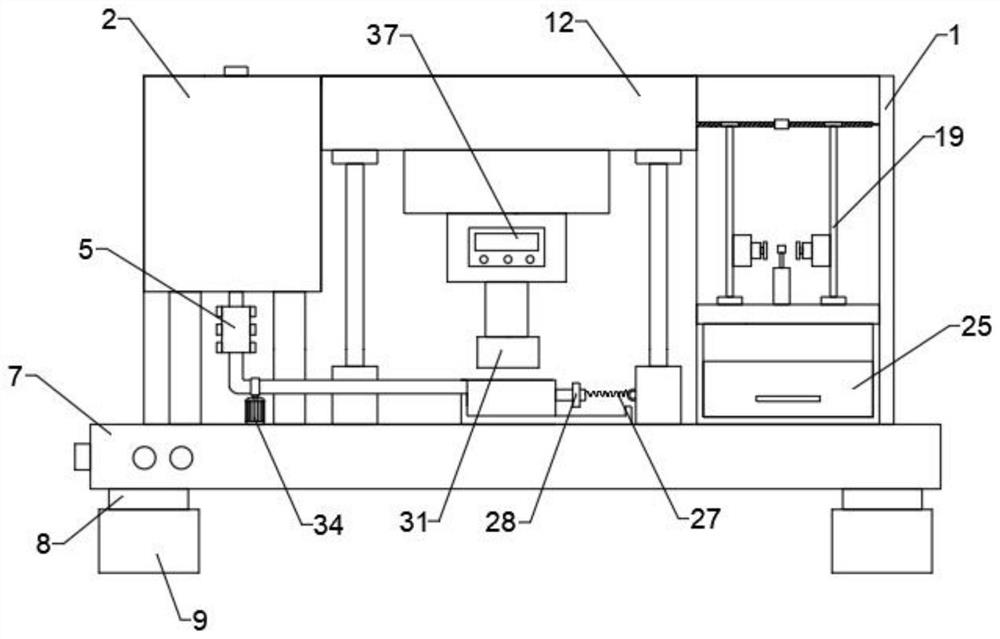

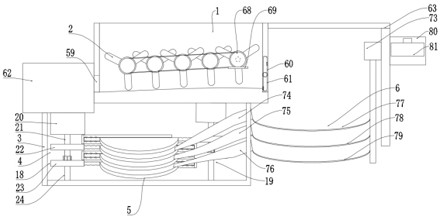

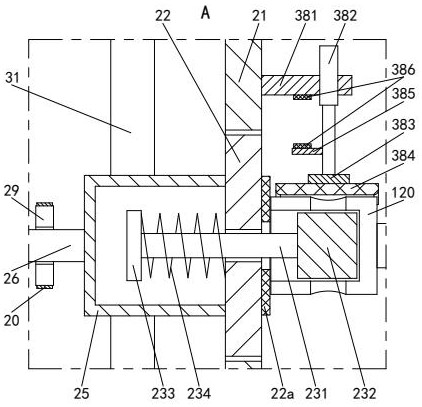

Pipe surface grinding processing device

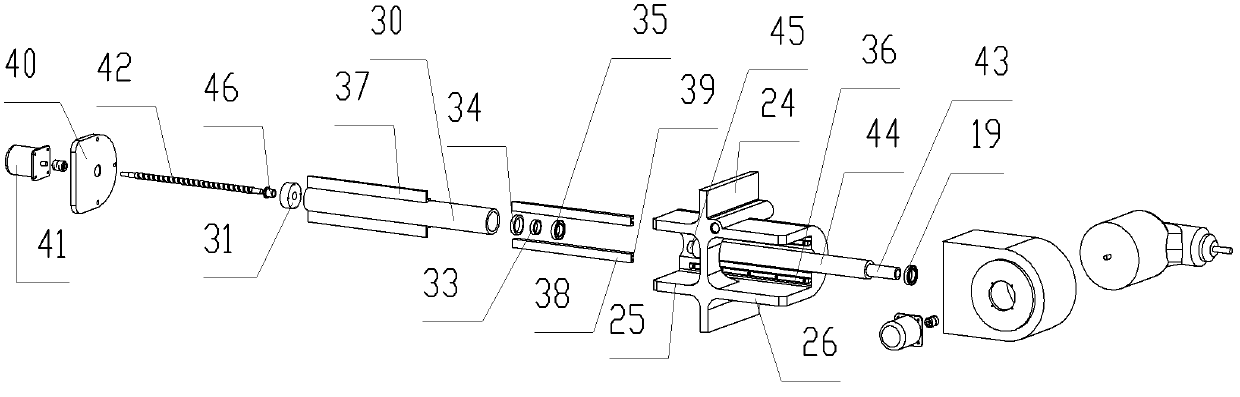

InactiveCN111975476ARealize rotary feedAchieving infeedRevolution surface grinding machinesGrinding work supportsEngineeringSurface grinding

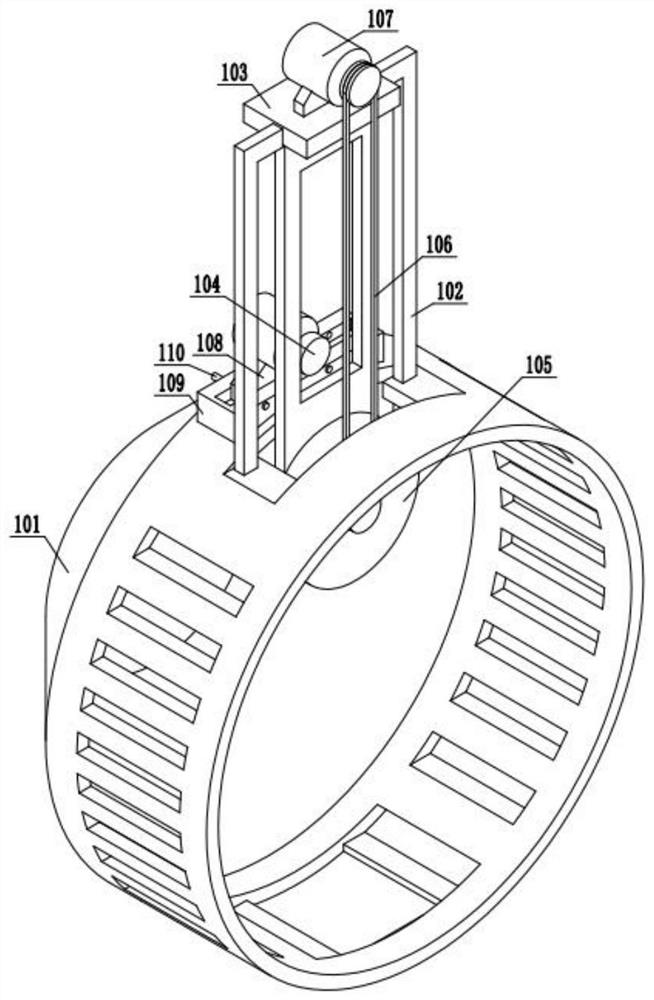

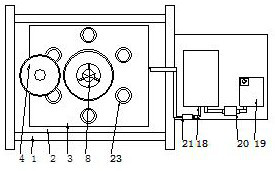

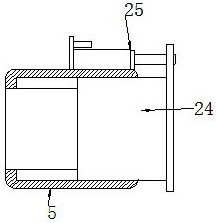

The invention relates to a pipe surface grinding device, in particular to a pipe surface grinding processing device. The device comprises a grinding structure, a supporting and grinding structure, a steel pipe fixing structure, a fixed support plate and a fixed base, wherein the grinding structure is fixedly installed on the supporting grinding structure, the fixing structure is installed on the fixed base in a sliding manner, the fixed support plate is fixedly installed on the fixed base, the supporting and grinding structure is fixedly installed on the fixed support plate, and the grinding structure is fixedly installed on the fixed base. A plurality of ventilation grooves are arranged on an outer casing of the device, and can effectively achieve the function of cooling. When too much heat is generated, the grooves formed in the outer casing can be conveniently connected with an external cooling device, and a grinding wheel of the device can rotate together with a steel pipe, so thatthe grinding efficiency is higher. The device is provided with two stages of grinding mechanisms, the steel pipe can be ground repeatedly, and grinding is more thorough.

Owner:哈尔滨金玉钰科技开发有限公司

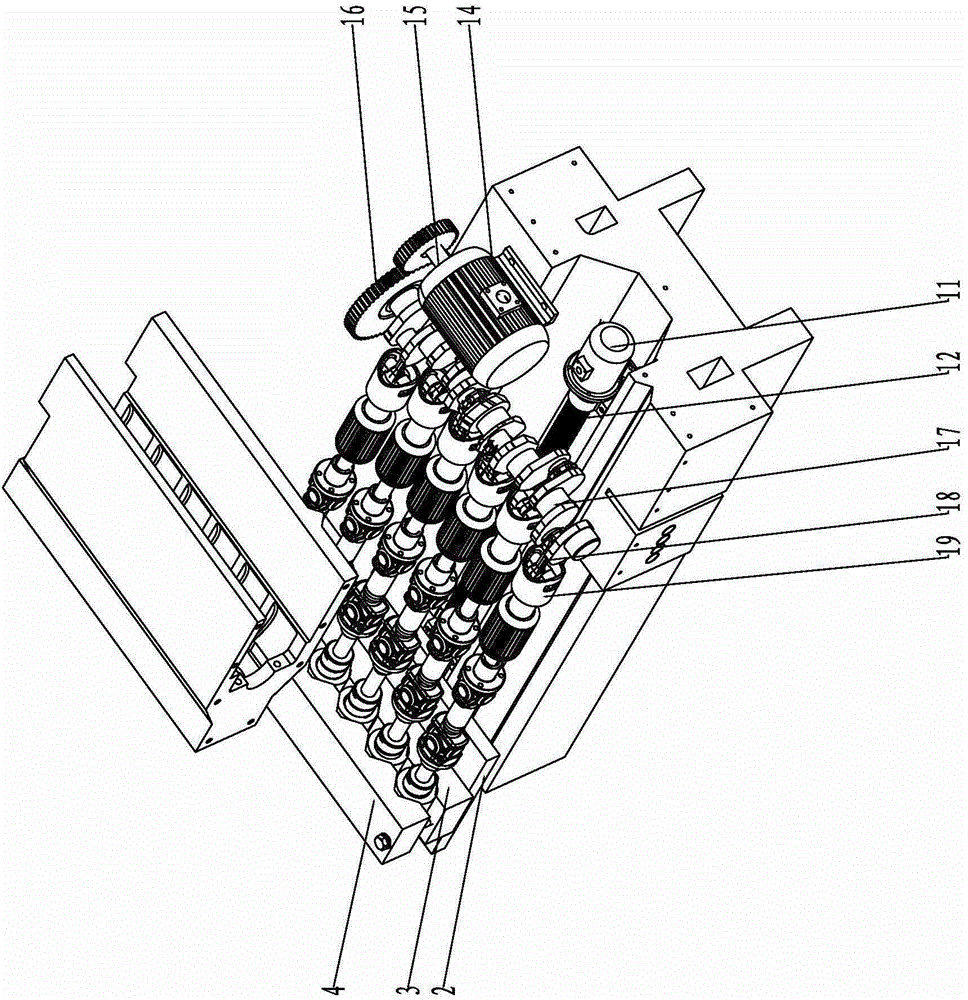

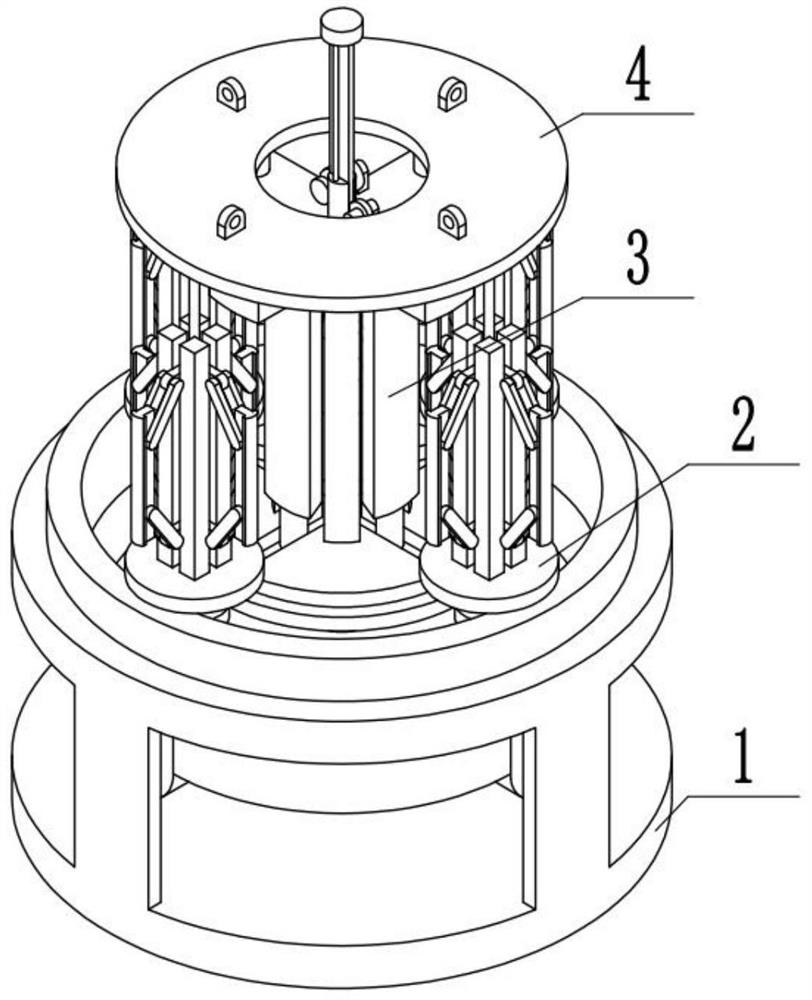

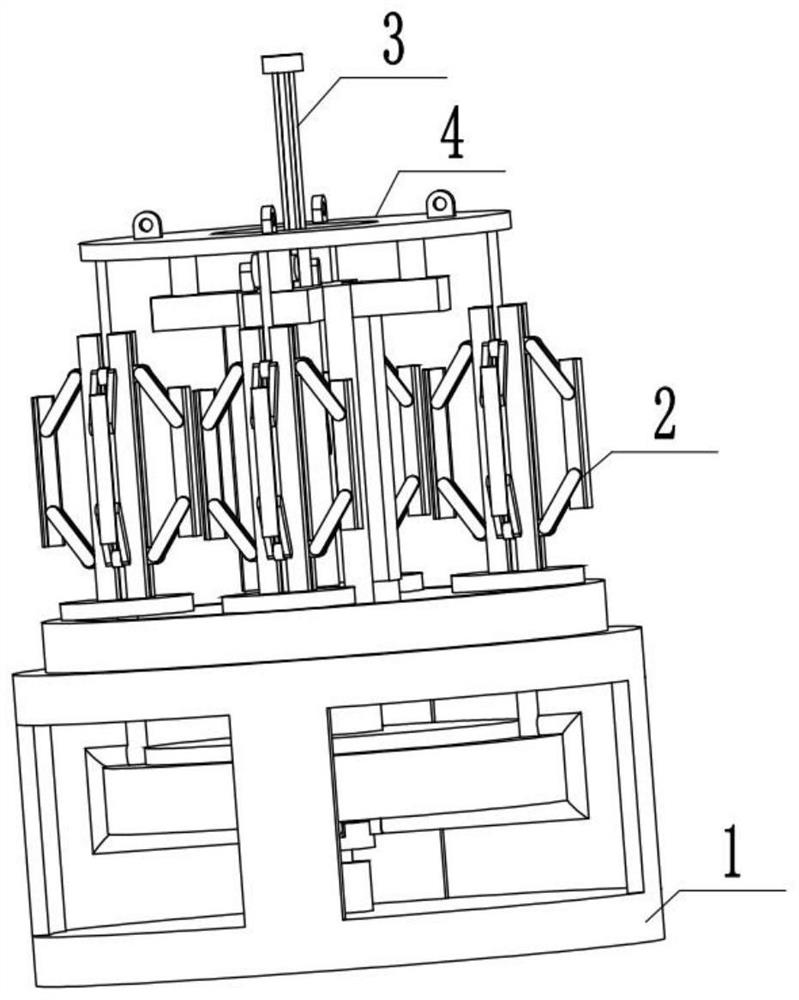

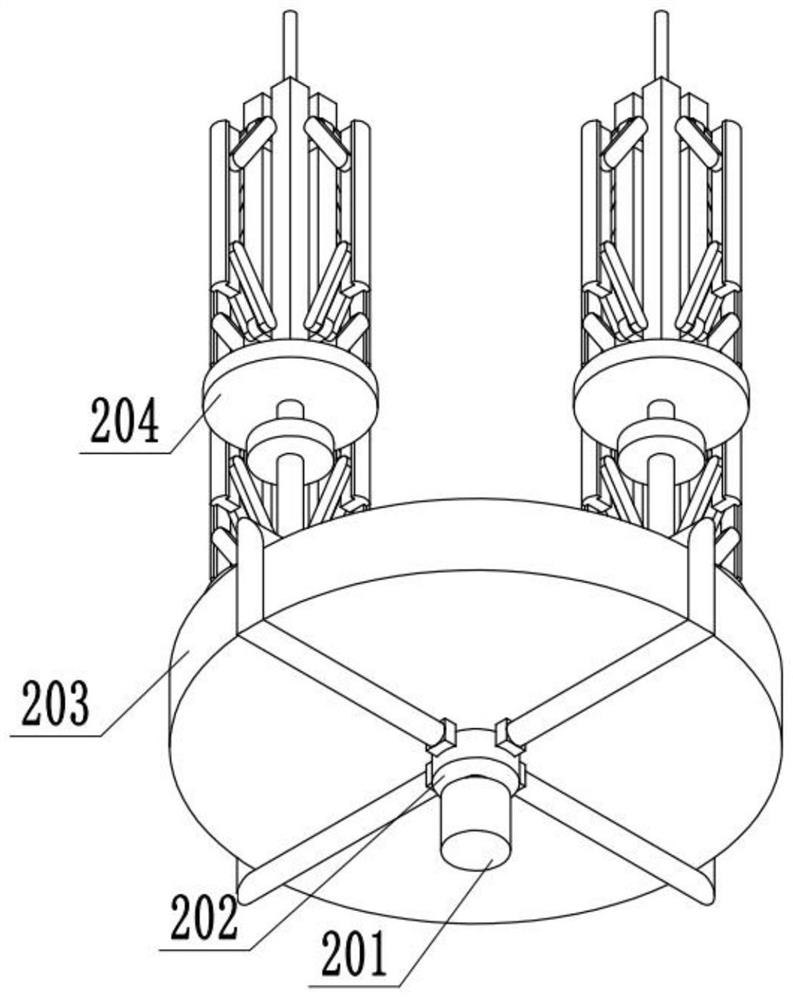

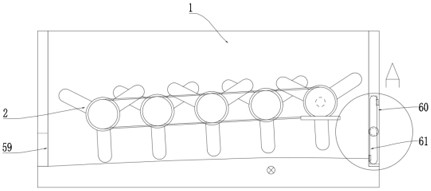

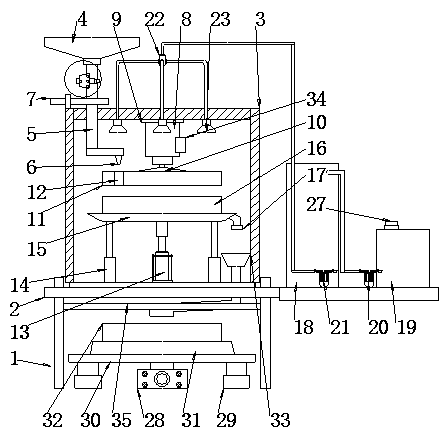

Automatic multiple-shaft grinding machine

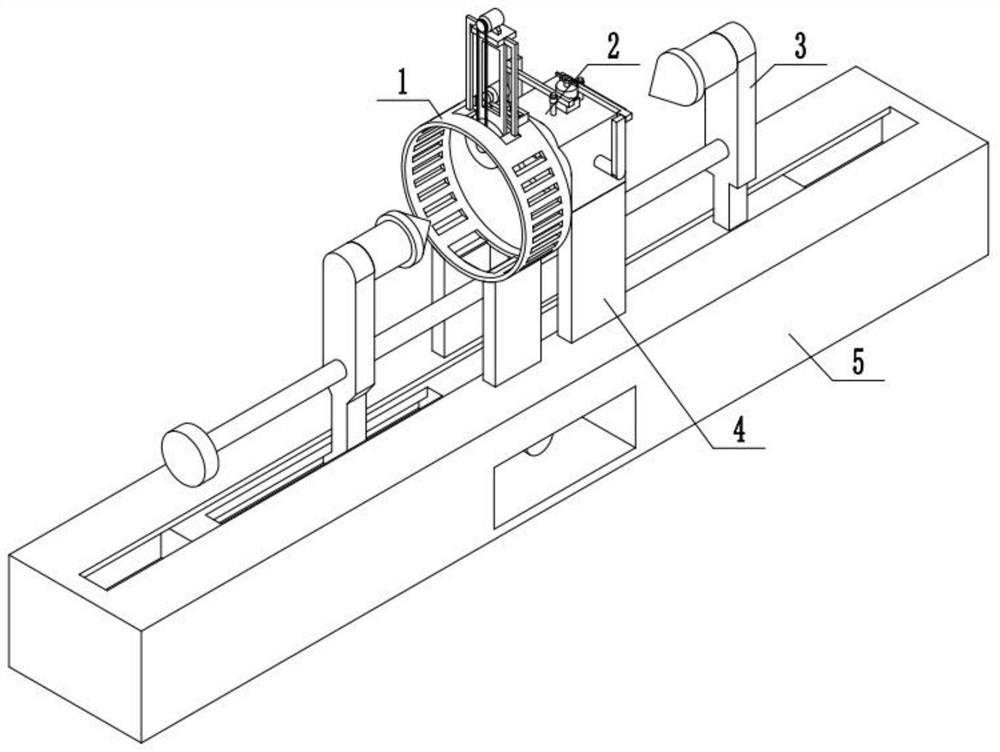

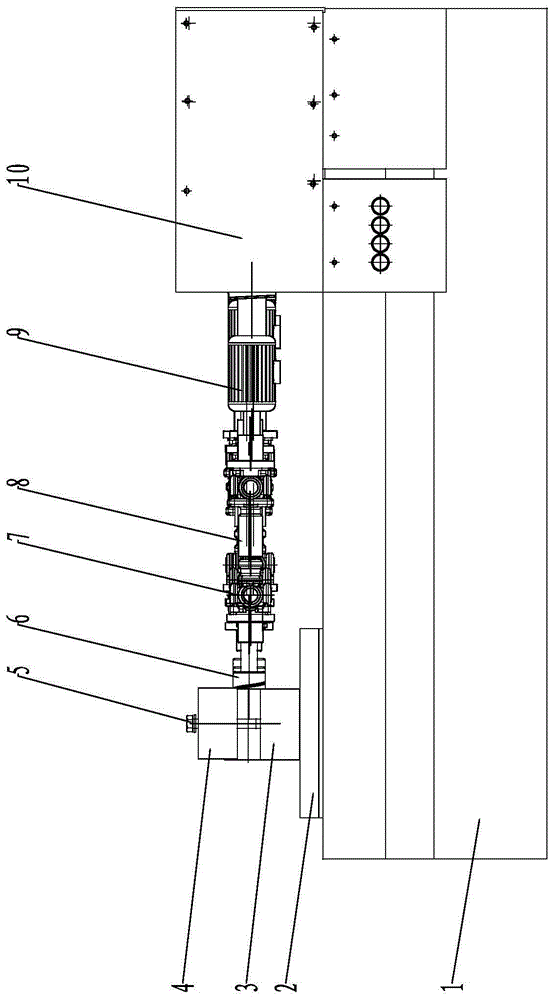

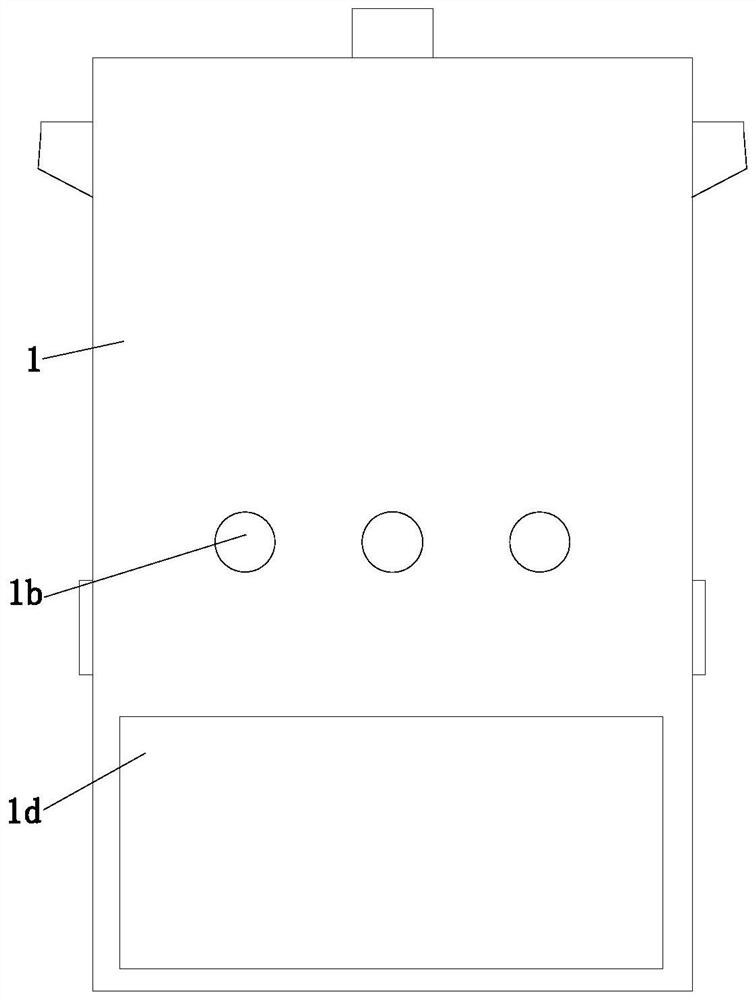

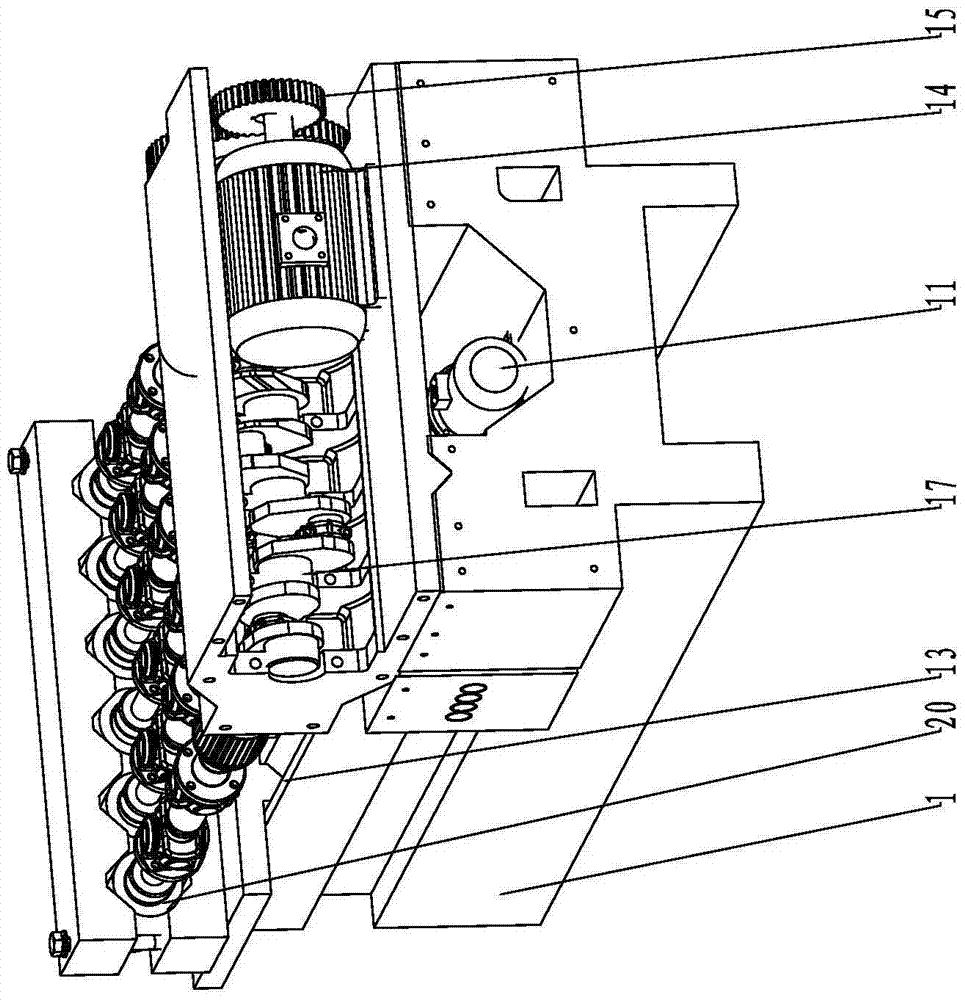

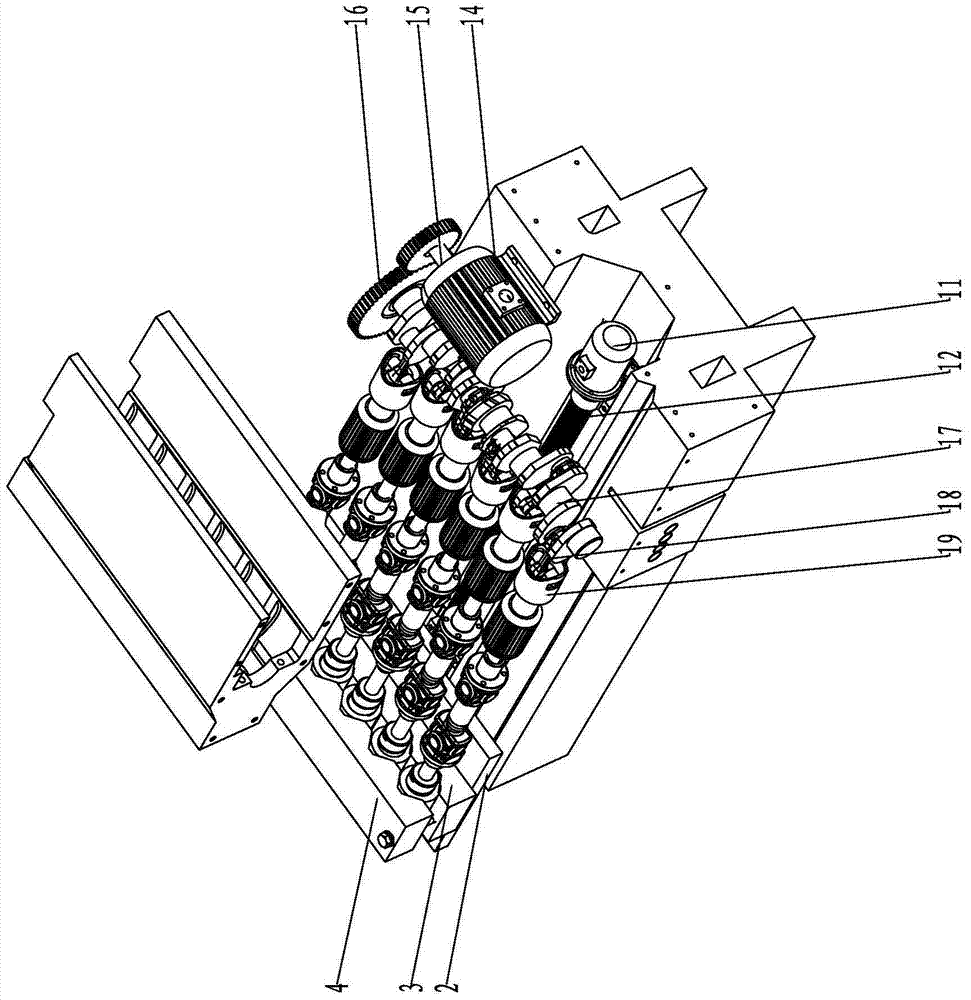

The invention relates to a grinding machine, in particular to an automatic multiple-shaft grinding machine and belongs to the technical field of grinding machines. The automatic multiple-shaft grinding machine comprises a grinding machine tool body, wherein a workpiece positioning tray is arranged at the left end of the grinding machine tool body. A workpiece clamping component is fixed to the workpiece positioning tray, multiple workpiece clamping cavities are formed in the workpiece clamping component, and one part can be clamped in each workpiece clamping cavity. The number of grinding heads is equal to the number of the workpiece clamping cavities, one workpiece clamping cavity is correspondingly arranged on the axis of each grinding head, and each grinding head conducts reciprocating grinding on the workpiece in the correspondingly formed workpiece clamping cavity. The automatic multiple-shaft grinding machine adopts the multiple-shaft grinding heads and can simultaneously conduct automatic grinding on the outer circles and inner holes of multiple parts, machining efficiency is improved, a crankshaft connecting rod mechanism is adopted, and a multiple-shaft radial and axial automatic grinding function is achieved.

Owner:鹰普航空科技有限公司

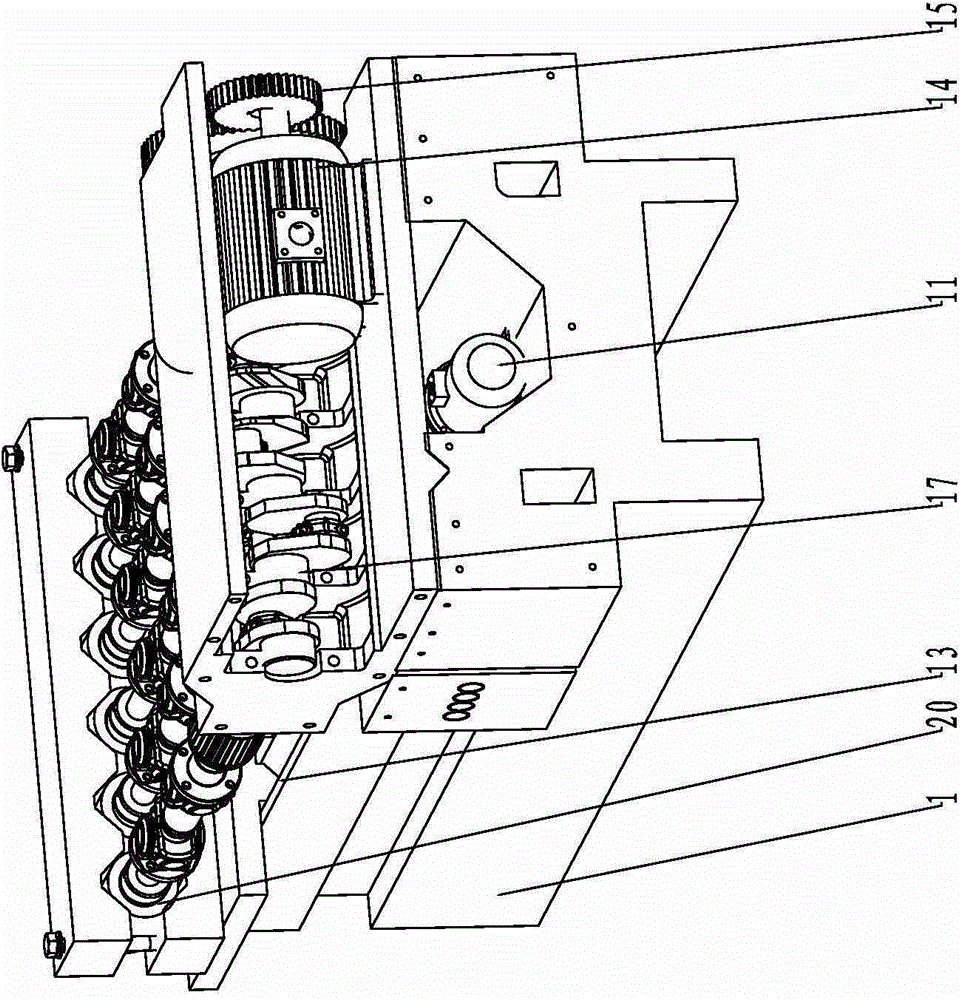

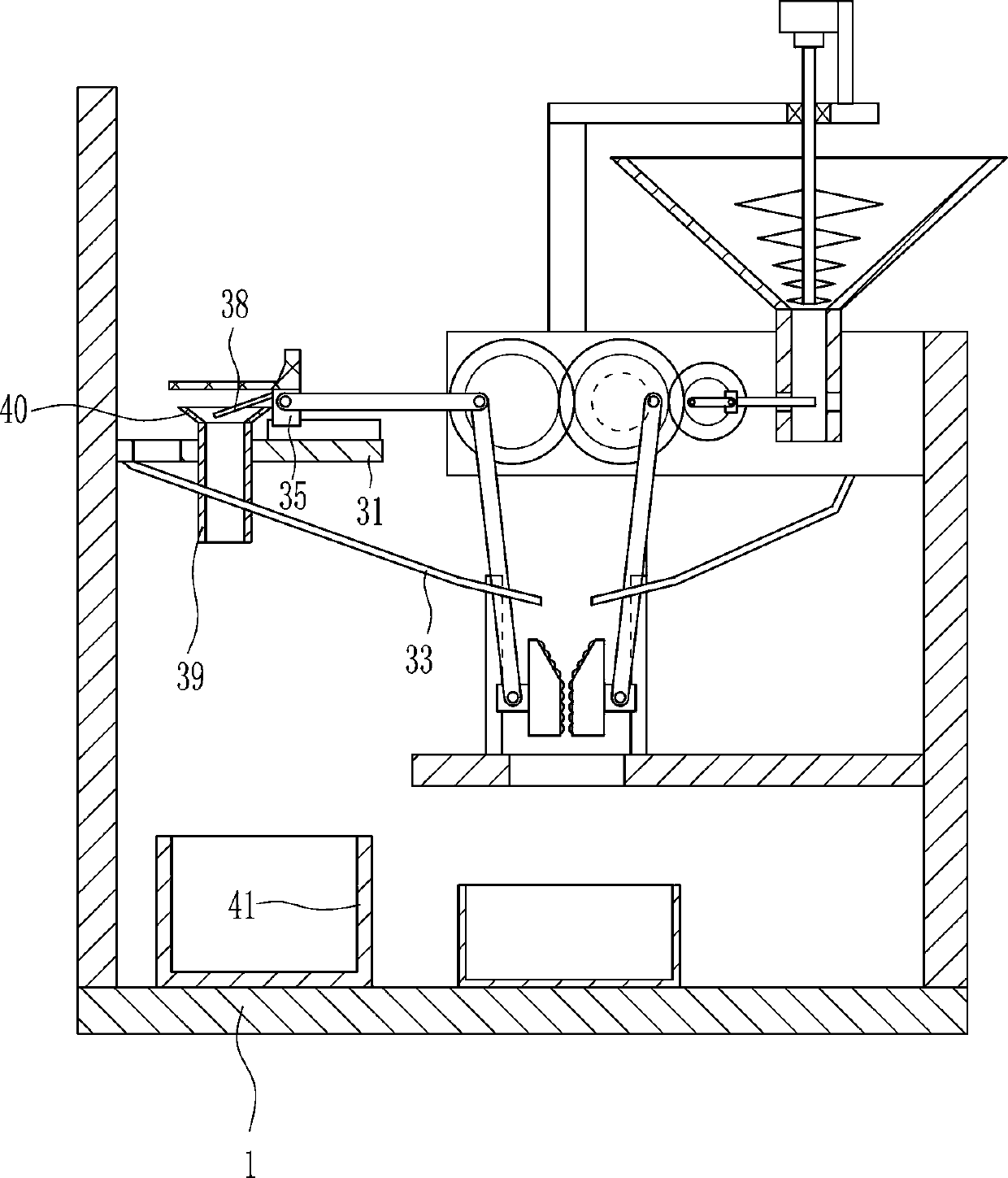

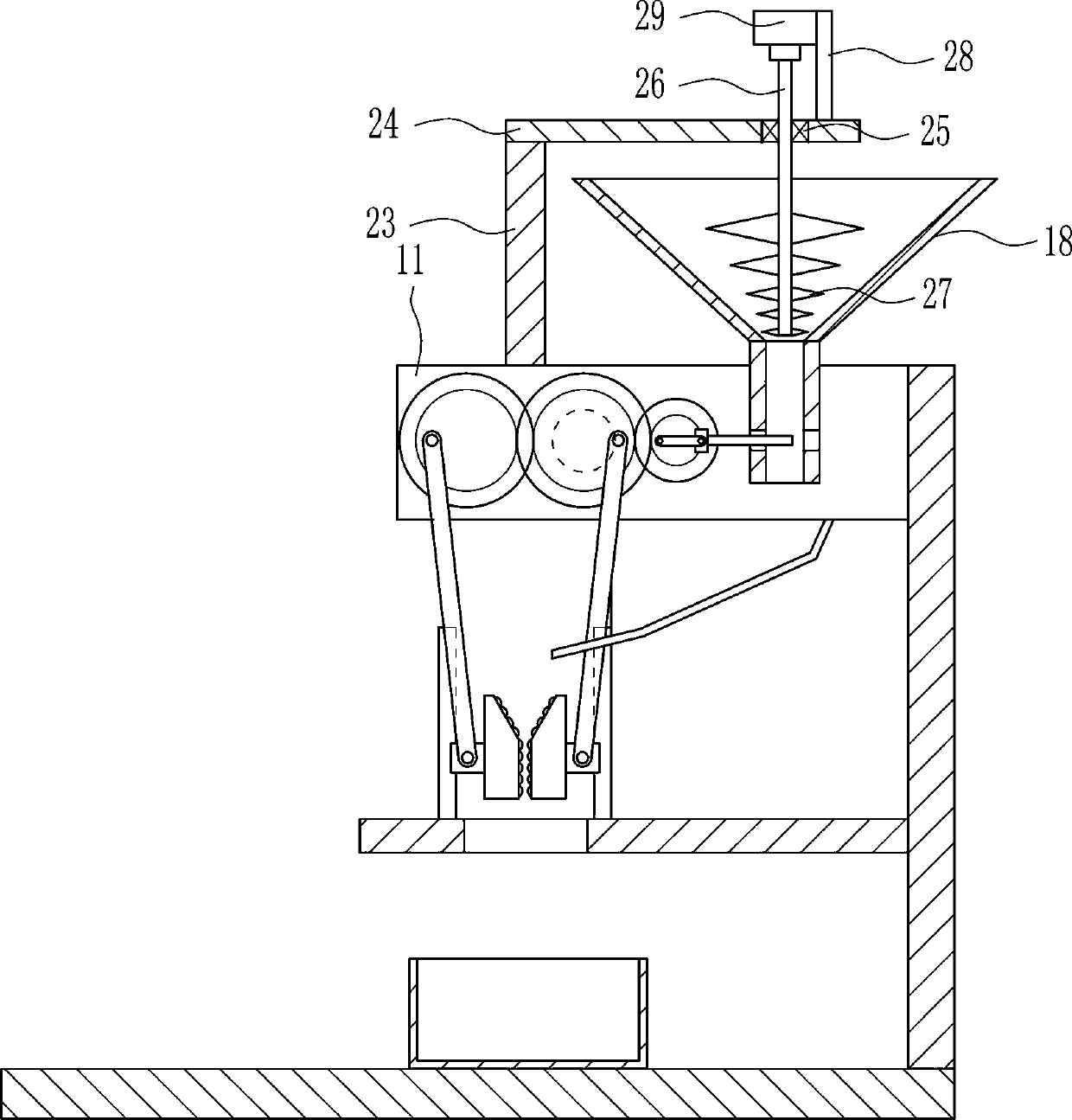

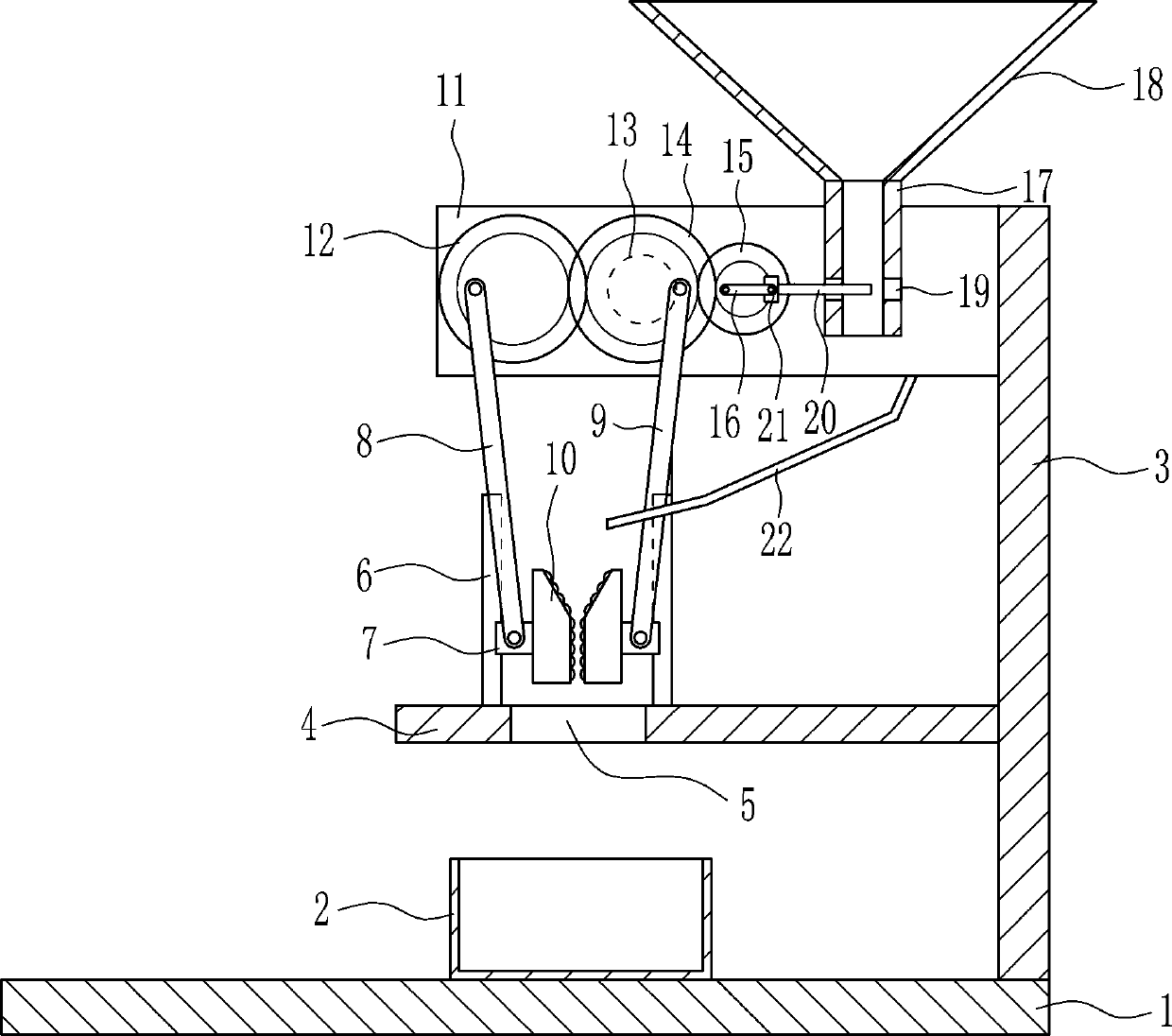

Grinding and processing equipment for graphene material

The invention discloses grinding and processing equipment for a graphene material. The grinding and processing equipment comprises base frames, a base plate and a shell, wherein the base plate is fixed on the base frames, and the shell is placed on the base plate; a feeding unit is arranged on the outer wall of the shell, and a grinding unit is arranged in the shell; a material receiving unit is arranged between the base frames, and a cleaning unit is arranged on the base frames; the feeding unit comprises a feeding mechanism and a flow control mechanism; the feeding mechanism comprises a collection hood, a feeding pipeline and a feeding mouth; the feeding pipeline is placed above the shell through a stabilizing frame, the collection hood is fixed at the port of the feeding pipeline, the feeding mouth is connected to the lower end of the feeding pipeline, an opening of the feeding mouth faces downwards; and the grinding unit comprises an upper grinding mechanism and a lower grinding mechanism. The grinding and processing equipment has the beneficial effect that the true grinding equipment with a cleaning function is realized based on a material extrusion function.

Owner:TAIZHOU LAI & KE INTELLIGENT TECH CO LTD

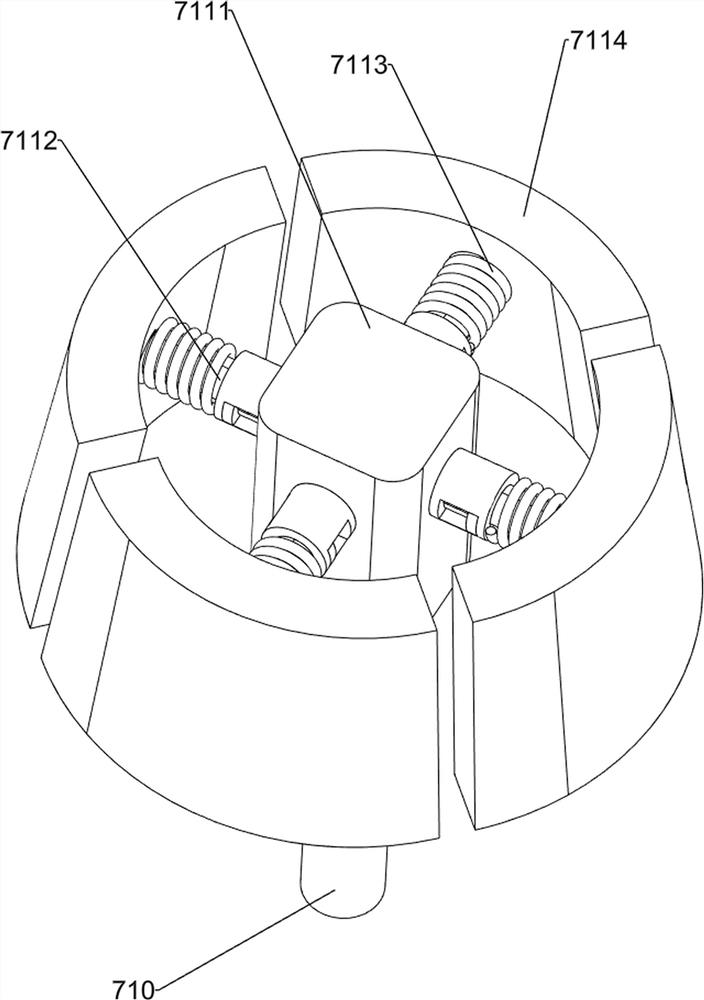

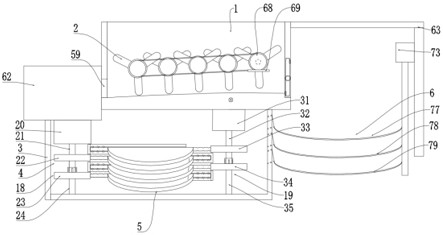

Pipe excircle grinding device for industrial production

ActiveCN112959148AEasy to fixLimit lateral displacementRevolution surface grinding machinesGrinding work supportsEngineeringPhysics

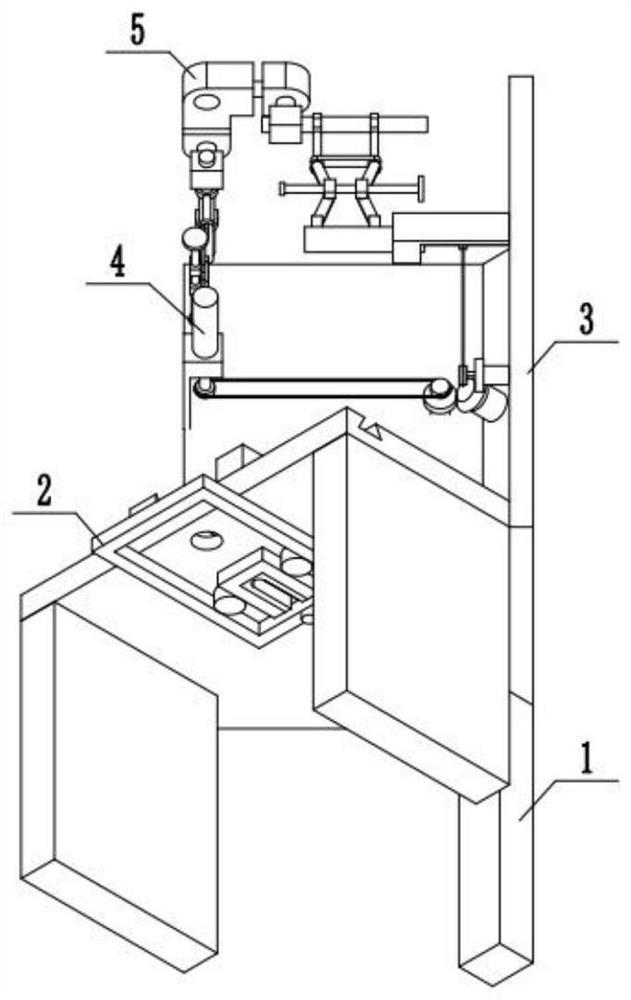

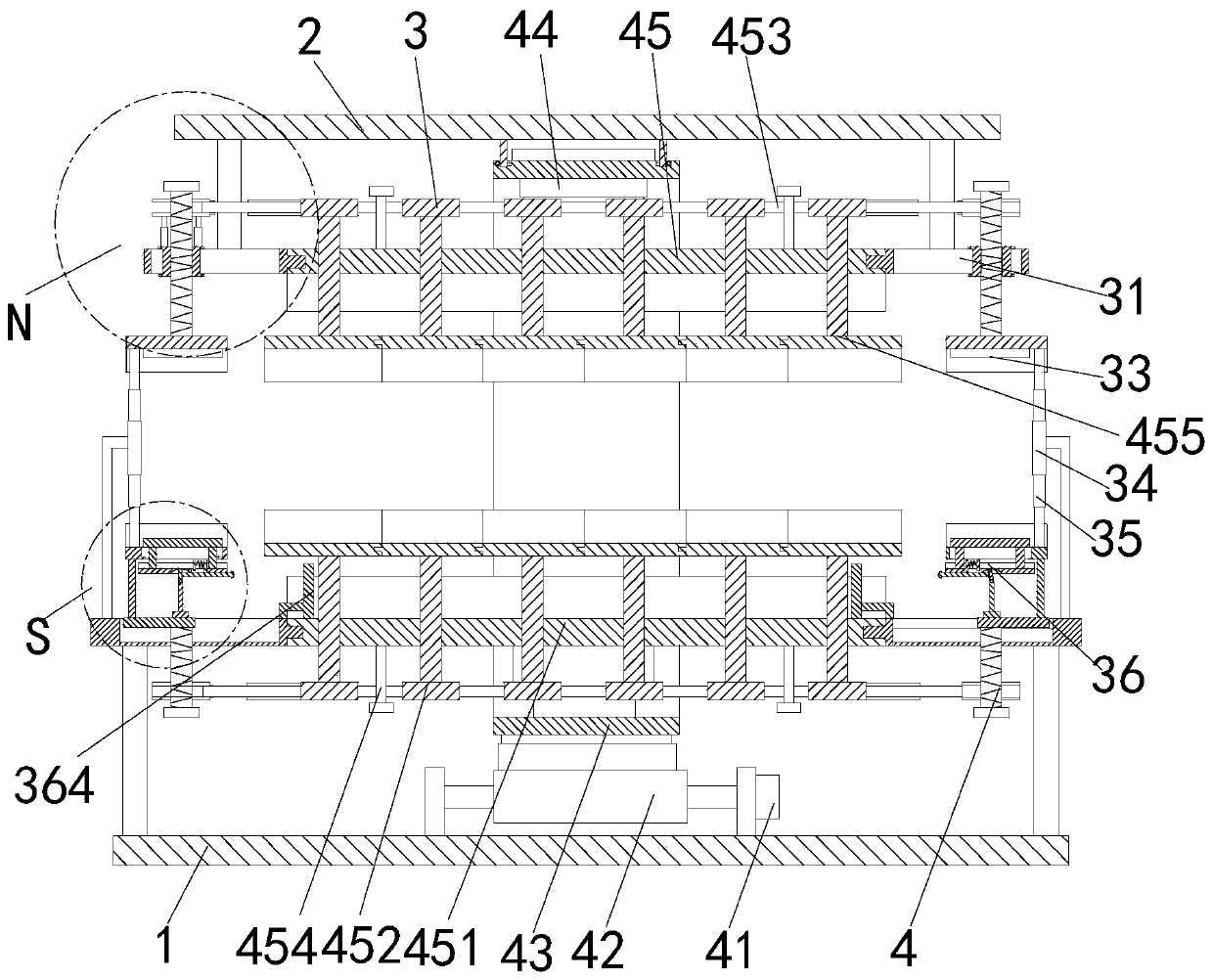

The invention relates to an excircle grinding device, in particular to a pipe excircle grinding device for industrial production. The pipe excircle grinding device comprises a fixed bottom frame, pipe fixing devices, a pipe grinding device and upper cover plates, wherein the pipe fixing devices are fixedly arranged on the fixed bottom frame, the plurality of pipe fixing devices are arranged, the pipe fixing devices are arranged on the pipe grinding device, and the upper cover plates are arranged on the pipe fixing devices. Multiple supporting and limiting devices are arranged inside the device, so that movement is stabler, and pipe rotation and revolution are adopted in the device, so that grinding is more uniform, when the device is used for grinding, a pipe makes overall contact with a grinding plate, and the situation that the grinding plate works at a single position, and a grinding groove is generated, so that the grinding plate is damaged is prevented.

Owner:大连近江汽车零部件有限公司

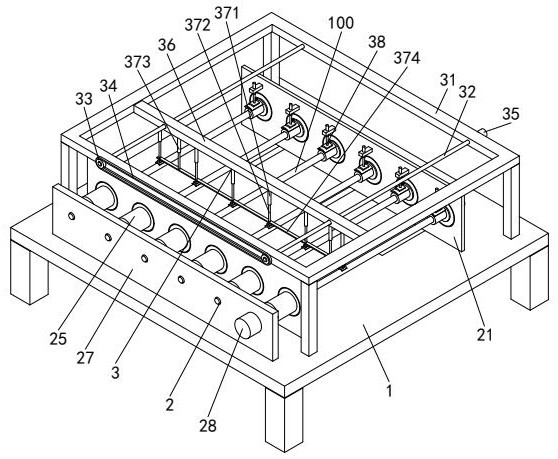

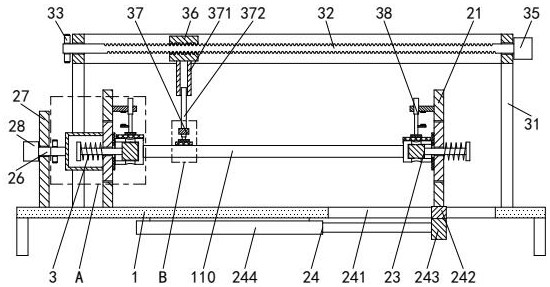

Semi-formed wooden barrel bottom surface grinding device

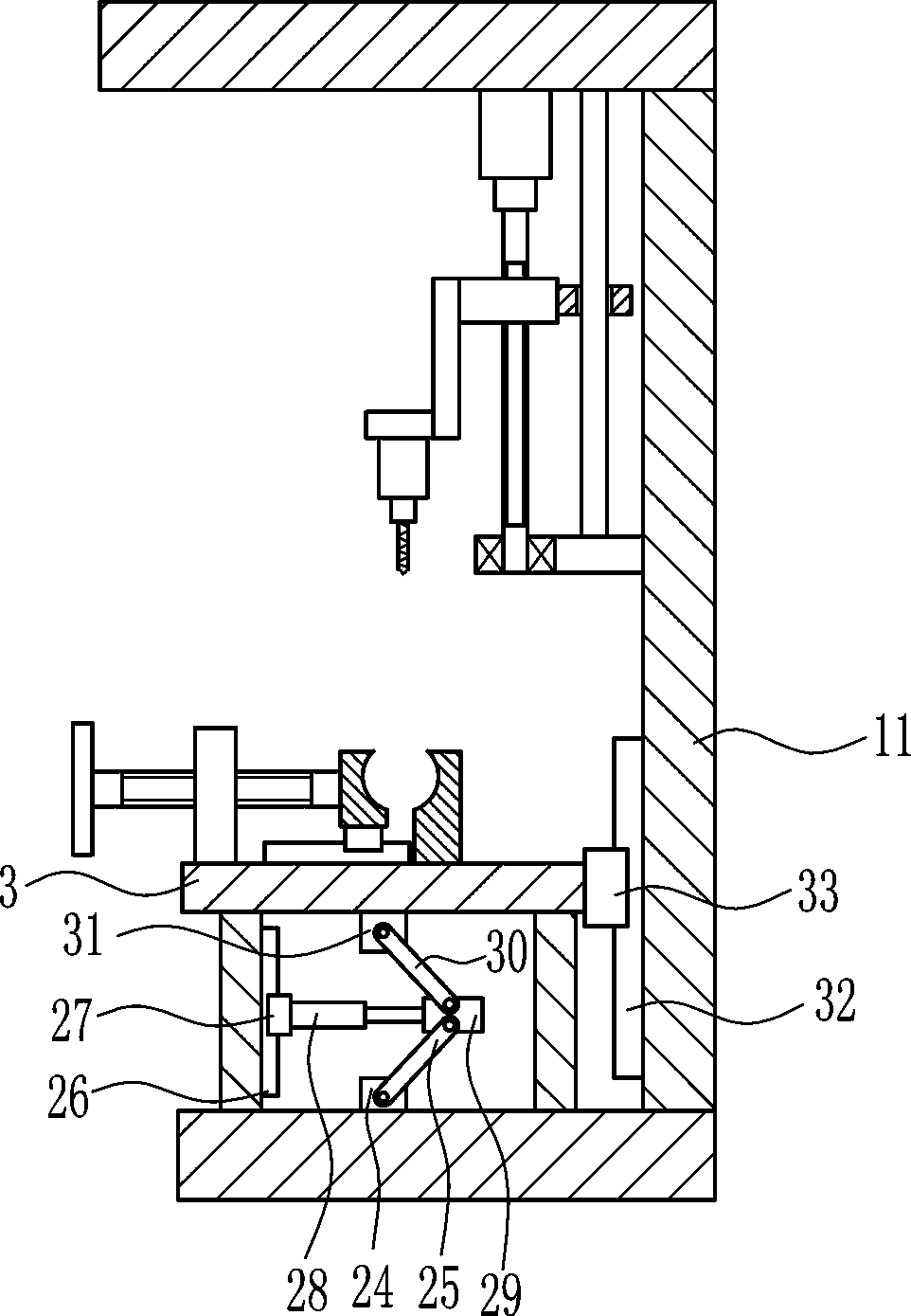

PendingCN112123067ARealize the function of grindingAvoid random movementGrinding carriagesGrinding drivesElectric machineEngineering

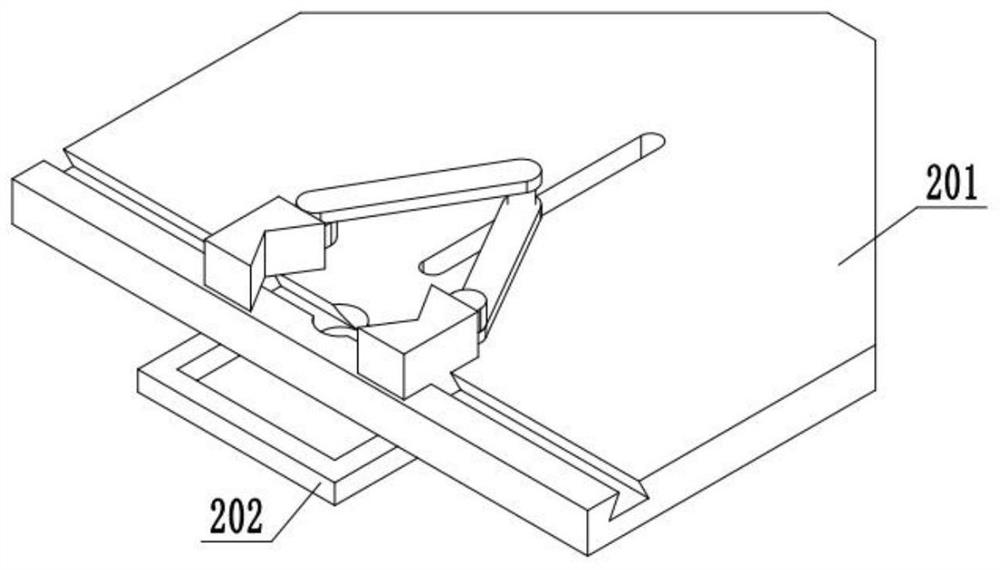

The invention relates to a grinding device, in particular to a semi-formed wooden barrel bottom surface grinding device. The semi-formed wooden barrel bottom surface grinding device is high in automation strength, manually lifting of a wooden barrel for a long time is not needed, the precision is high, and the situation that the workers are injured by being cut is avoided. The semi-formed wooden barrel bottom surface grinding device comprises a base, a power motor, an operation table and a grinding mechanism, wherein a workbench is arranged at the top of the base; the power motor is mounted onone side of the top of the workbench; the operation table is arranged at the top of the workbench, and the power motor and the operation table are located on the same horizontal line; and the grinding mechanism is arranged at the top of the workbench. By arranging the grinding mechanism, the function of grinding a wooden barrel can be achieved; and by arranging a clamping steering mechanism whichis used for clamping the wooden barrel, the wooden barrel is prevented from moving at will in a grinding process, the wooden barrel does not need to be manually lifted, and the effect of reducing thelabor intensity is achieved.

Owner:曹紫梅

Hardware wrench forming finish machining device

ActiveCN113386023ARealize the clamping functionEffective sandingGrinding carriagesGrinding machinesPolishingEngineering

The invention relates to the technical field of hardware wrench finish machining, in particular to a hardware wrench forming finish machining device which comprises a workbench, a clamping mechanism and a polishing mechanism. The workbench is provided with the clamping mechanism and the polishing mechanism. According to the hardware wrench forming finish machining device, matching blocks are mounted in a detachable mode so that the matching blocks of different specifications can be conveniently and rapidly replaced, the function of clamping tire wrenches of different specifications is achieved, and the practicability of the device is improved; and through the characteristics of an elastic telescopic rod, the function that a first grinding block and a second grinding block are attached to the outer surface of a wrench connecting rod and the end outer surface of a wrench all the time is achieved, and the problem that the grinding effect is poor due to the uneven surface of the tire wrench is solved.

Owner:江苏优霸五金工具有限公司

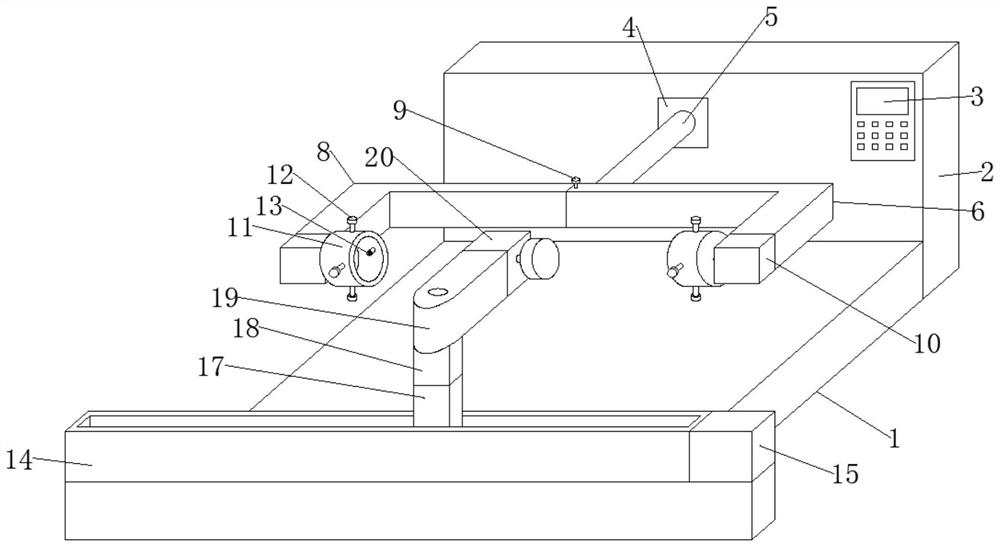

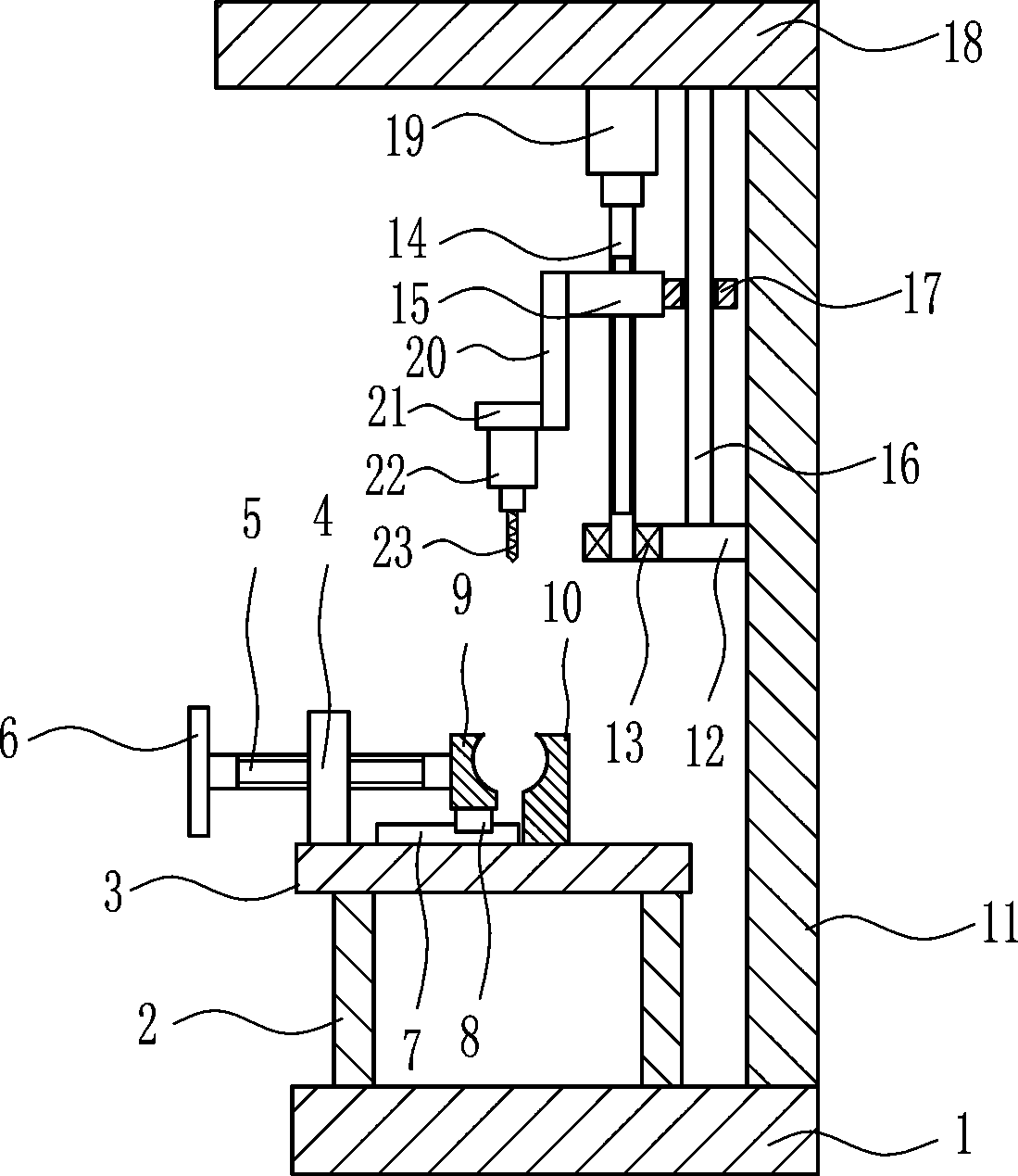

Punching equipment of teaching abacus bead

ActiveCN108297189ARealize the function of punchingRealize lifting functionEdge grinding machinesPolishing machinesPunchingEngineering

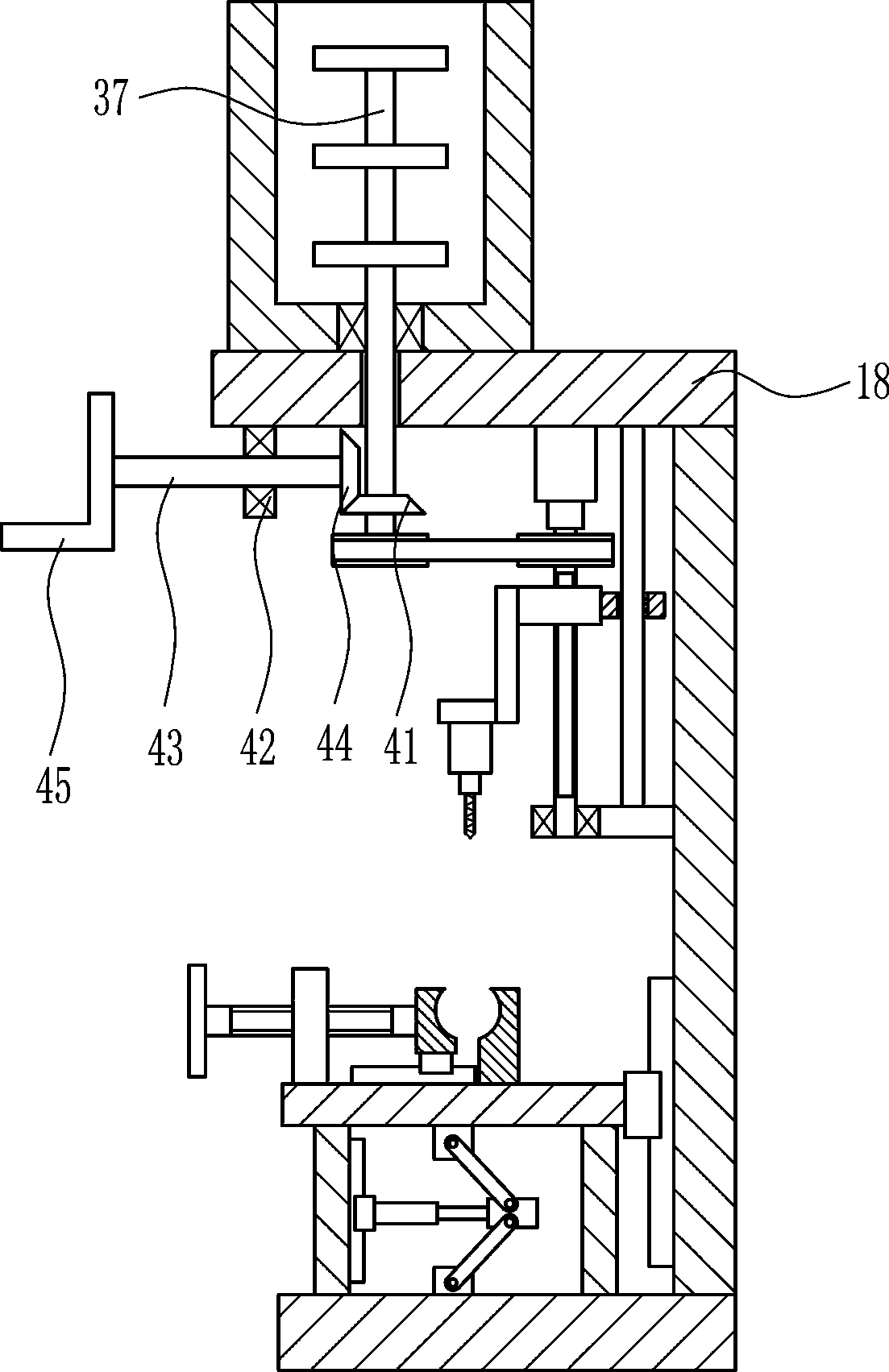

The invention relates to punching equipment, in particular to punching equipment of a teaching abacus bead. The invention aims to provide the punching equipment of the teaching abacus bead which is convenient to use and easy to operate. In order to solve the technical problem, the invention provides the punching equipment of the teaching abacus bead. The equipment comprises a base, first supports,a support plate, a first nut, a first screw rod, a first rotary plate, a first sliding rail, a first sliding block, a first clamp, a second clamp and the like, wherein two first supports are fixedlyconnected to the base, the supporting plate is arranged on the two first supports, and the first nut is fixedly connected to the left side of the upper portion of the base, the first screw rod is matched in the first nut, and the first rotary plate is fixedly connected to the left end of the first screw rod. According to the equipment, the function of punching the abacus bead is achieved, not onlythe function of lifting the supporting plate is achieved, but also the function of grinding the abacus bead with punched hole is achieved.

Owner:辛秋萍

Bar and pipe polishing and grinding device for machining

InactiveCN112658827ARealize the function of longitudinal clampingClamp firmlyRevolution surface grinding machinesGrinding drivesPolishingEngineering

The invention relates to a polishing and grinding device, in particular to a bar and pipe polishing and grinding device for machining. The bar and pipe polishing and grinding device comprises a fixed supporting base, a bar and pipe fixing device, a V-shaped baffle, a grinding driving device and a grinding device. The fixed supporting base is fixedly mounted below the bar and pipe fixing device, the V-shaped baffle is fixedly mounted on the bar and pipe fixing device, the grinding driving device is mounted on the V-shaped baffle, and the grinding device is mounted on the grinding driving device. According to the bar and pipe polishing and grinding device, bars and pipes can be automatically clamped, four-way force is used for clamping, clamping is more stable, the grinding and polishing range can be adjusted according to the use condition, the applicability is higher, and the bar and pipe polishing and grinding device can automatically grind bars and pipes, and grinding is more uniform.

Owner:哈尔滨市阿城区胜达建筑材料厂

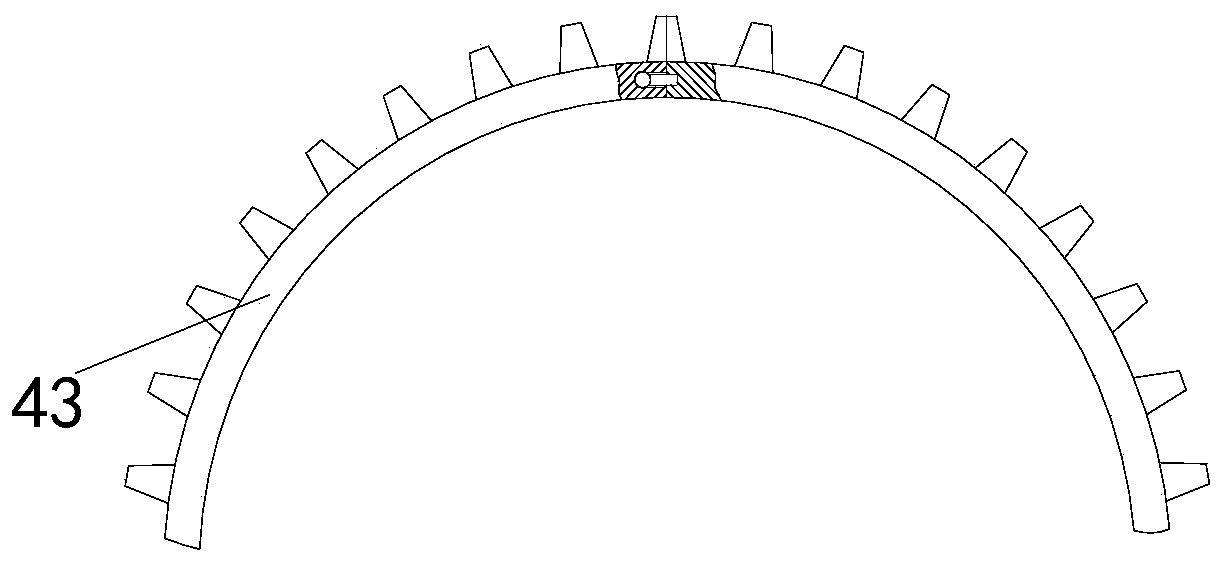

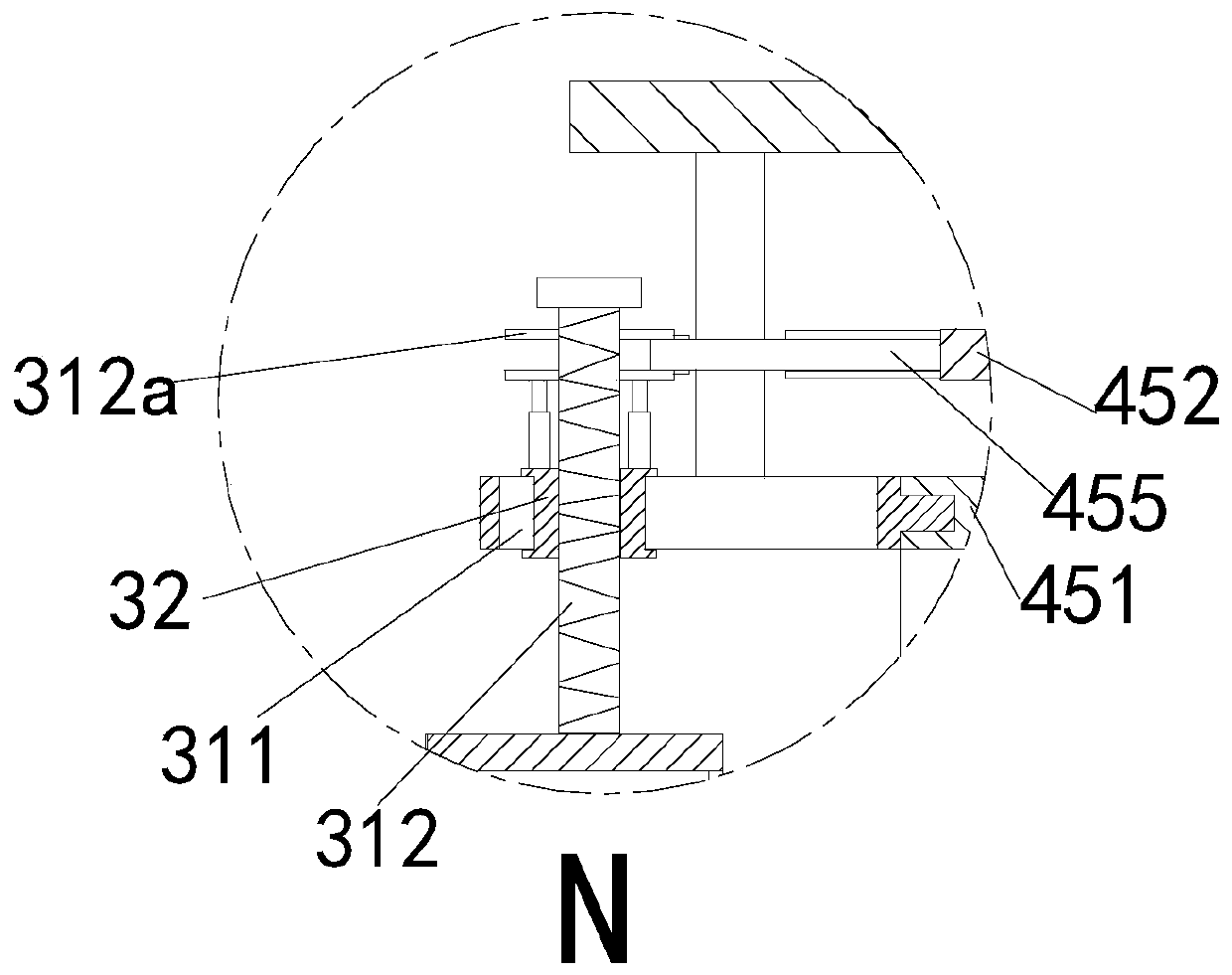

Crystal rod outer diameter grinding equipment for semiconductor devices

ActiveCN110561264AReduce stepsImprove grinding precisionLapping machinesWork carriersPower semiconductor deviceButt joint

The invention relates to crystal rod outer diameter grinding equipment for semiconductor devices. The equipment comprises a worktable, a mounting frame, a support mechanism and a grinding mechanism; the support mechanism is mounted at the upper end of the worktable; the mounting frame is arranged at the upper end of the support mechanism; the grinding mechanism is mounted at the lower end of the mounting frame, and comprises a driving motor, a driving gear, a driven gear, a connecting plate and a grinding support chain; the support mechanism comprises a butt joint branch chain, a slide block,a pressing plate, a fixed plate, an extension plate, a support branch chain and an electric slide block; and the grinding support chain comprises a working plate, an adjusting rod, a transverse plate,an adjusting bolt and a grinding plate. Through cooperation of the support mechanism and the grinding mechanism during working, the equipment achieves the purpose of alternately clamping the left andright ends of crystal rods, so that the overall grinding work of the crystal rods is once finished, the operation steps are reduced, the grinding precision is improved, the clamping of the crystal rods by a manual mode is not needed, and the centering precision is improved.

Owner:奥准企业发展上海有限公司

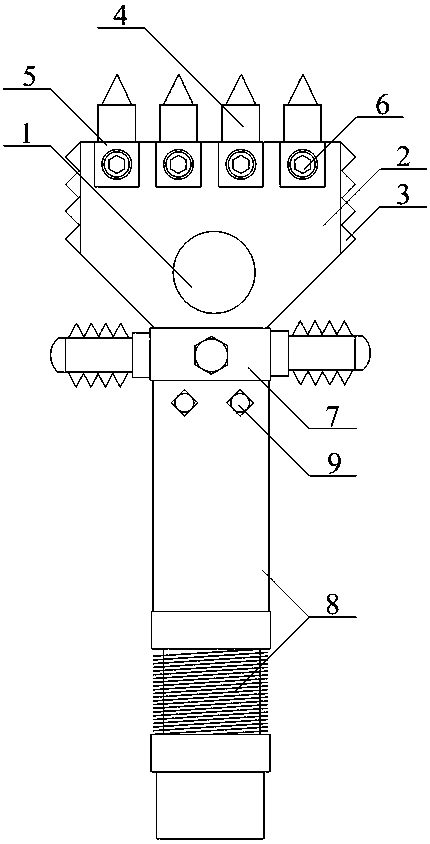

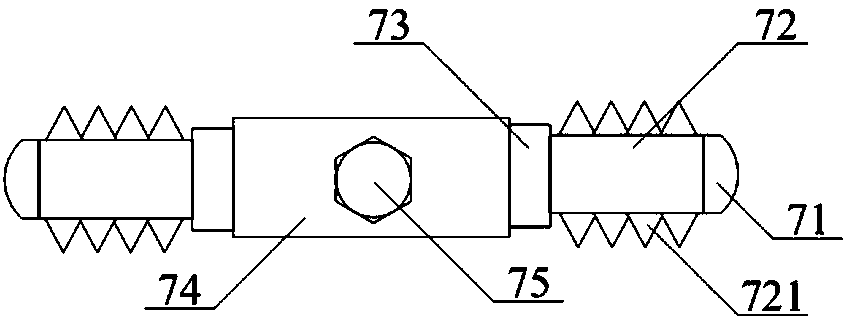

Multifunctional diamond drill bit for ores and working principle of multifunctional diamond drill bit

InactiveCN107859488AImprove work efficiencyGuarantee mining efficiencyDrill bitsConstructionsEngineeringDrill bit

The present invention provides a multifunctional mining diamond drill bit and its working principle, which includes a chip removal hole, a main drill bit, diamond auxiliary drill teeth, a detachable small drill bit, slots, hex socket socket bolts, mine wall correction tooth structure, The extension rod structure and fastening bolts, the chip removal hole is set in the middle position of the inner lower side of the main drill bit; four or more diamond auxiliary drill teeth are set as a group and are longitudinally inlaid on the left and right sides of the main drill bit. The setting of the adjusting screw rod, the first-level fastening nut, the adjusting sleeve, the second-level fastening nut and the drill bit fixing pipe of the present invention can be adjusted according to the needs, so that the work efficiency can be improved and the mining efficiency can be guaranteed; the small diamond drill bit body , the setting of the drill seat, the socket block and the socket slot can be easily disassembled, replaced or cleaned and reused, so as to make the operation more convenient.

Owner:HENAN GUANGDU SUPERHARD MATERIAL CO LTD

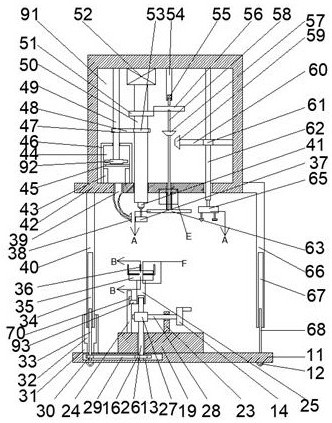

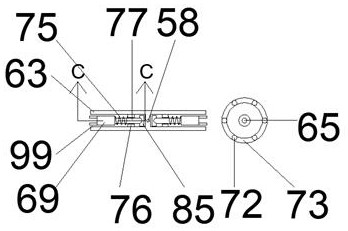

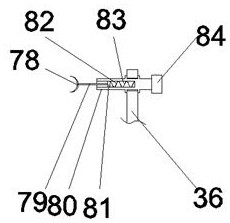

Generator valve seat ring machining device

PendingCN111872797AShorten the timeImprove work efficiencyShaping toolsGrinding drivesMotor vehicle partElectric generator

The invention discloses a generator valve seat ring machining device, and belongs to the field of car parts. The device comprises a box body and a base, a storage chamber is installed at the top end in the box body, a heating block is installed at the bottom end in the storage chamber, a feeding port is formed in the middle of the upper end of the storage chamber, a storage pipe is installed in the middle of the bottom end in the storage chamber, and a water pump is installed at the lower end of the storage pipe; and first supporting columns are arranged at the left side and the right side ofthe lower end of the storage chamber, a workbench is mounted at the lower end of the box body, the lower ends of the two first supporting columns are fixedly connected with the left portion of the upper end of the workbench, a fixing chamber is installed in the middle of the top end in the box body, fixing columns are installed at the left side and the right side of the lower end of the fixing chamber, the lower ends of the two fixing columns are fixedly connected with the middle of the upper end of the workbench, and a fixing block is mounted at the lower end of the fixing chamber. Accordingto the device, a seat ring is taken out by pulling a handle, and after the seat ring is taken out, a second spring restores elasticity and returns to the original position, so that the seat ring is convenient to take, the time is saved, and the operation efficiency is improved.

Owner:太仓昌鑫船舶机械有限公司

Gem grinding device capable of automatically changing tool and collecting dust

InactiveCN112548784ARealize the function of grindingReduce manual operationsGrinding drivesGrinding machinesHydraulic cylinderRotational axis

The invention discloses a gem grinding device capable of automatically changing tool and collecting dust. The gem grinding device comprises a supporting wall, a closed supporting cavity is formed in the supporting wall, a motor is fixedly connected to the inner wall of the upper side of the supporting cavity, a main machine shaft is in power connection with the lower end of the motor with the center of the motor as the datum line, and a left movable wheel is fixedly connected to the periphery of the main machine shaft; and the lower end of the main machine shaft is fixedly connected with a fastening cylinder, a grinding wheel is installed at the lower end of the fastening cylinder in a threaded mode, and a rotatable rotating shaft is arranged on the lower side of the supporting wall and close to the right side of the motor. Grinding and dust absorption treatment only need to be conducted under the action of the motor, under the action of a hydraulic cylinder, the needed tool can be replaced, so that manual operation is reduced, an operation table can be lifted up and down through a manual handle, and therefore the complete gem grinding function is achieved.

Owner:南京晋亿达智能技术有限公司

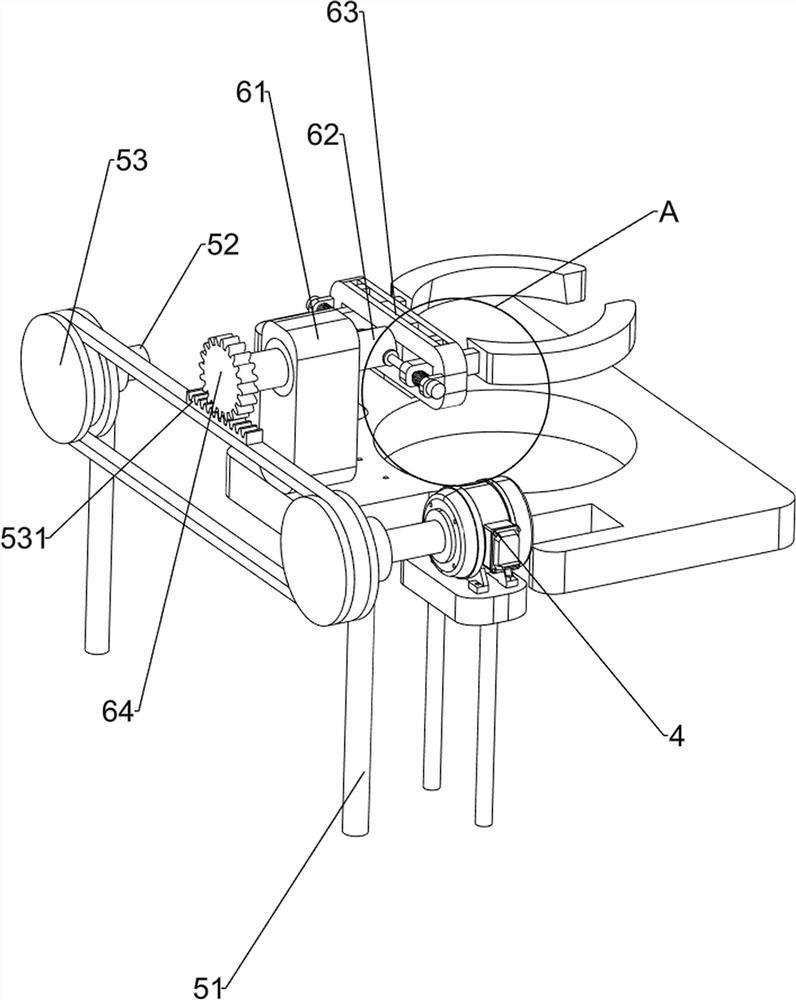

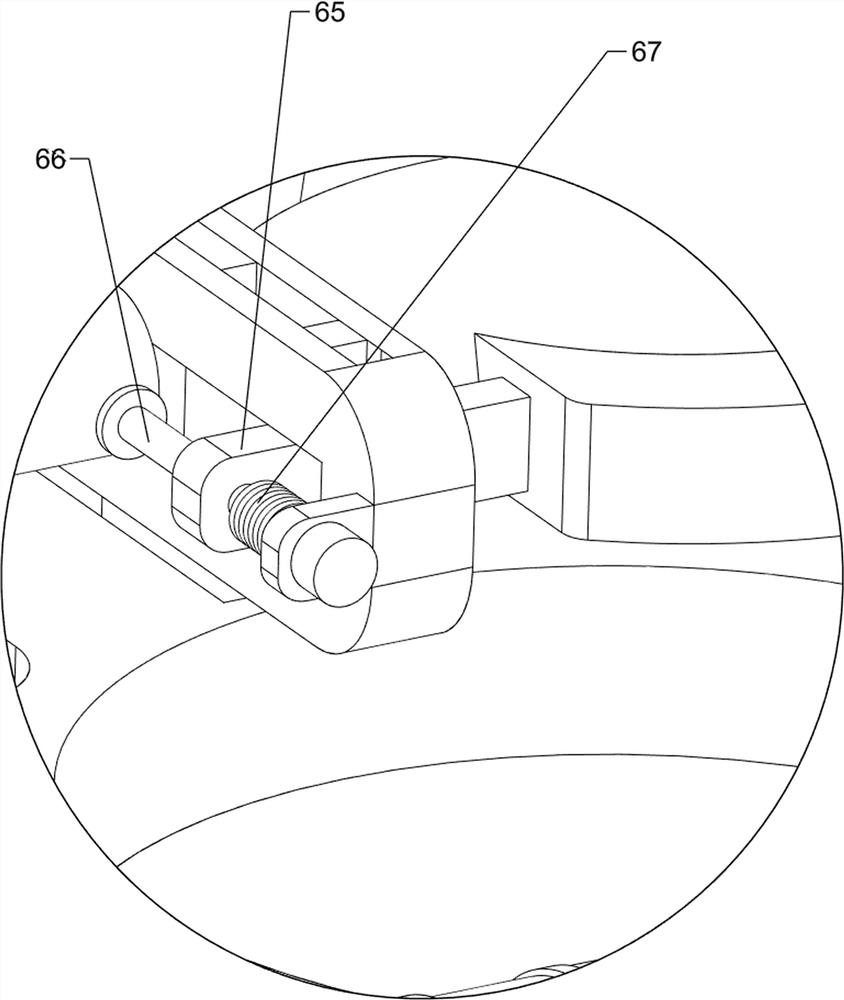

Cutter grinding device

InactiveCN112059748AFixed effect is stableEffective positioningGrinding drivesOther manufacturing equipments/toolsGrindingEngineering

The invention relates to the field of machining and manufacturing, in particular to a cutter grinding device. The cutter grinding device comprises shifting gears and bases, grinding adjusting mechanisms, a position adjusting mechanism, a one-way power mechanism, an angle adjusting mechanism and a cutter fixing mechanism. The grinding adjusting mechanisms are mounted in grooves in the shifting gears and bases in a sliding manner. The shifting gears and bases are fixedly mounted on the two sides of the position adjusting mechanism correspondingly, the one-way power mechanism is fixedly mounted on the position adjusting mechanism, the angle adjusting mechanism is fixedly mounted on the position adjusting mechanism, and the cutter fixing mechanism is fixedly mounted on the angle adjusting mechanism. The device has the function of adjusting the grinding angle and the grinding direction, different grinding manners are adopted for different kinds of cutters, the functions that the grinding effect is optimal and the cutter height is specifically adjusted are achieved, the device adapts to cutters with different widths, the function of adjusting the single-time grinding distance is achieved, and the device adapts to cutters with different lengths.

Owner:哈尔滨市阿城区胜达建筑材料厂

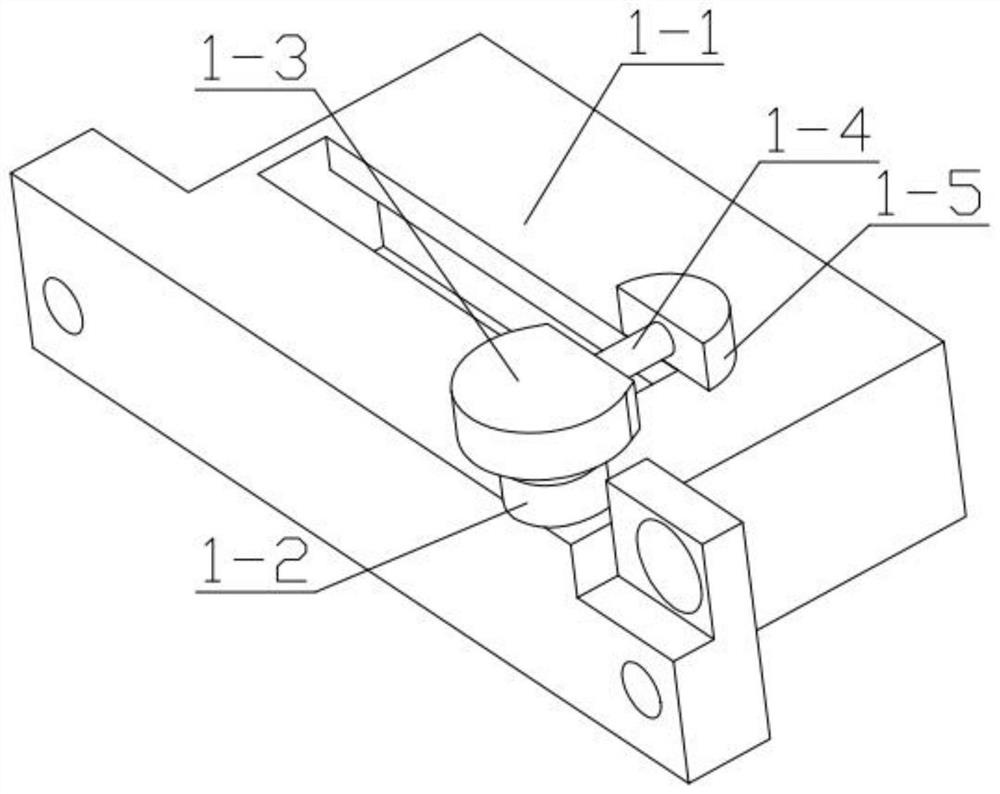

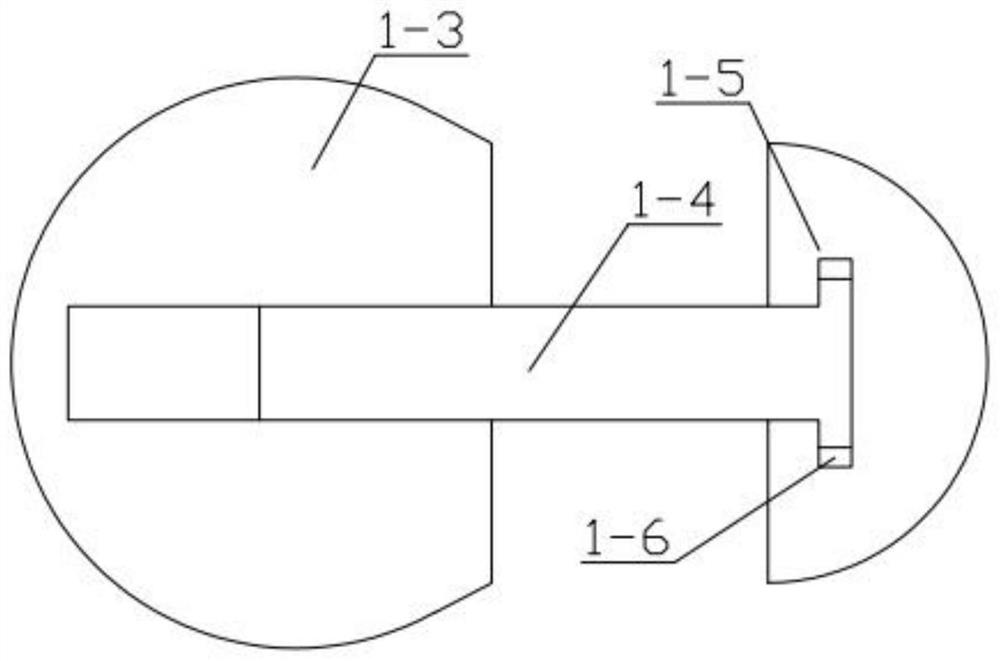

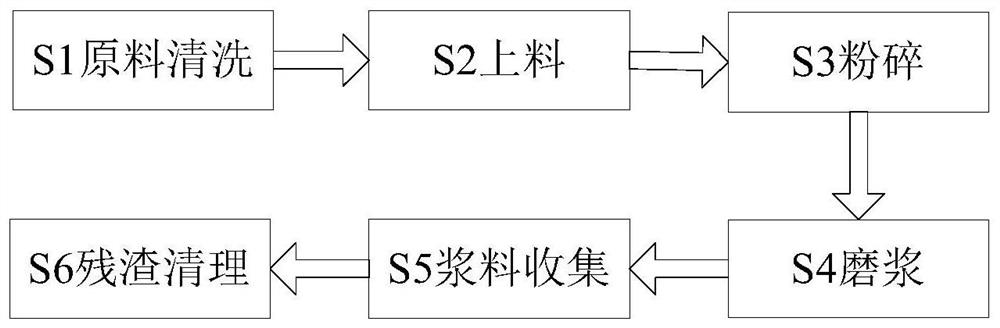

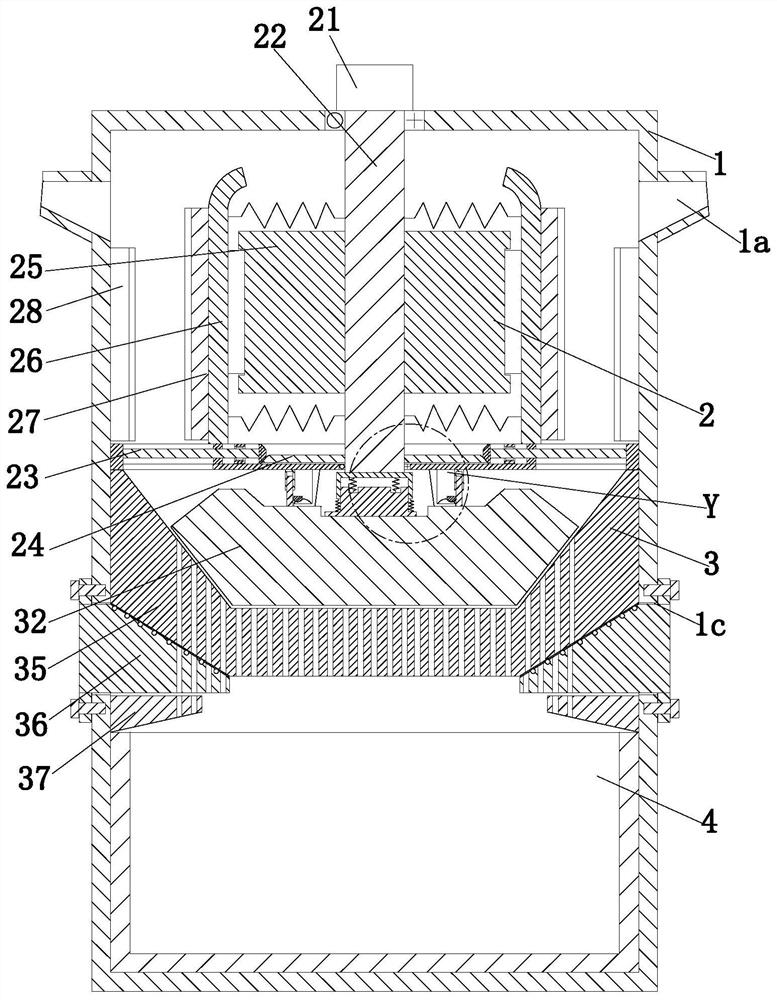

A plant essential oil preparation raw material crushing and grinding process

The invention relates to a crushing and refining processing technology for preparing raw materials of plant essential oils, which uses an automatic crushing and refining equipment, the crushing and refining equipment includes a working box, a crushing device, a refining device and a collection box, and the crushing device includes a drive motor , driving rod, unloading mechanism, driving bevel gear, driving cam, moving knife holder, moving blade and fixed blade, the specific technological process when using the above-mentioned automatic crushing and refining equipment to process raw materials includes: raw material cleaning, feeding, crushing , Refining, slurry collection and residue cleaning. The present invention adopts the method of pulverizing first and then refining to grind the oil slurry from the raw material, and sends the crushed raw material into the refining device by intermittent feeding during the pulverizing process, which can make the raw material in the refining device Keep the dispersed state to ensure the sufficiency of grinding, and the space between the grinding disc and the material holding seat can be enlarged by dismantling the top block in the refining device, so as to clean up the residue.

Owner:大理巍檬生物科技有限公司

Hickory nut grinding and drying device for preparing hickory nut powder and using method thereof

InactiveCN112317088ARealize the function of shreddingRealize the function of grindingFood preservationGrain treatmentsWalnut NutMechanical engineering

The invention discloses a hickory nut grinding and drying device for preparing hickory nut powder and a using method thereof. The hickory nut grinding and drying device comprises a base, a mounting table is fixedly mounted at the top of the base, a grinding box is fixedly mounted at the top of the mounting table, a grinding assembly is arranged in the grinding box, and a mincing box is fixedly mounted on the outer wall of the top of the grinding box; and a discharging pipe is fixedly connected to the bottom of the mincing box, the bottom of the discharging pipe penetrates through the inner wall of the top of the grinding box and extends into the grinding box, and a discharging hopper is fixedly mounted at the top of the mincing box. According to the hickory nut grinding and drying device,hickory nut kernels are crushed in advance, so that the hickory nut kernels are ground more sufficiently; a screen is arranged, so that some particles which are not sufficiently ground can be filteredout, and the drinking taste is improved; and the hickory nut powder is stirred and dried to be prevented from being agglomerated, so that the hickory nut powder is dried more uniformly, the storage and transportation time of the hickory nut powder is prolonged, and the quality of the hickory nut powder is improved.

Owner:湖南鑫泉食品科技有限责任公司

Self-flowing swivel for concrete sand and gravel recovery and separation

ActiveCN114522763BAchieve self-shrinkageSave sanding timeSolid waste managementGrain treatmentsConcrete recyclingGrinding

The invention discloses a self-passing rotary member for recycling and separating concrete sand and gravel, comprising a concrete separation box, a self-passing rotary separation and recovery device, a sand and gravel grinding box, a grinding drive assembly, a counter-type two-way pressure grinding device and a screen assembly , the self-passing type rotary separation and recovery device is movably arranged in the concrete separation box; the sand and gravel grinding box is connected to the bottom wall of the concrete separation box, and the counter-type two-way pressure grinding device is movably arranged in the sand and gravel grinding box, and the The grinding drive assembly is arranged in the sand and gravel grinding box, and the grinding drive assembly is engaged with the counter-type two-way pressure grinding device; one end of the screen assembly is connected to the concrete separation box, and the other end of the screen assembly is connected to the sand and gravel. The grinding box is connected through. The invention belongs to the technical field of concrete recycling equipment, and specifically refers to a self-flow gyratory piece for recycling and separating concrete sand and gravel;

Owner:山西辰润交通科技有限公司

Surface grinding equipment for machined part

PendingCN114762945APlay the role of anti-slip protectionAdjustable lengthGrinding drivesGrinding machinesRubber materialMachine parts

The surface grinding equipment comprises a base, a working box is fixedly installed on the rear side of the base, a control panel is fixedly installed on the outer side of the working box, an air cylinder is fixedly installed in the working box, a pneumatic rod is arranged on the outer side of the air cylinder, a first clamping plate is fixedly installed on the front side of the pneumatic rod, and a second clamping plate is fixedly installed on the rear side of the first clamping plate. An extension plate is arranged on the inner side of the first clamping plate, and a second clamping plate is fixedly installed on the left side of the extension plate. According to the surface grinding equipment for the machined part, the machined part is installed in the fixing ring, all second bolts are rotated, the machined part is clamped, the machined part is protected in an anti-skid mode through the arrangement of an anti-skid pad rubber material, a first motor is started, the first motor drives the fixing ring to rotate, and therefore the machined part is driven to rotate, and if the machined part is a long-axis-shaped object, the machined part is clamped through the second bolts. And the first bolt is unscrewed, the extension plate is pulled open, the length of the device can be conveniently adjusted according to the length of the machined part, and the adaptability of the device is higher.

Owner:苏州佳伟电子有限公司

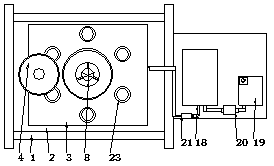

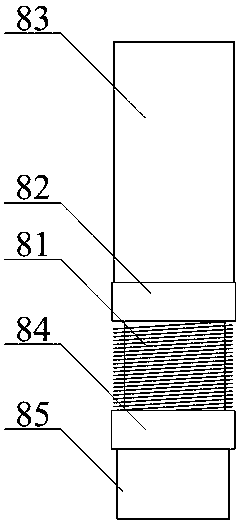

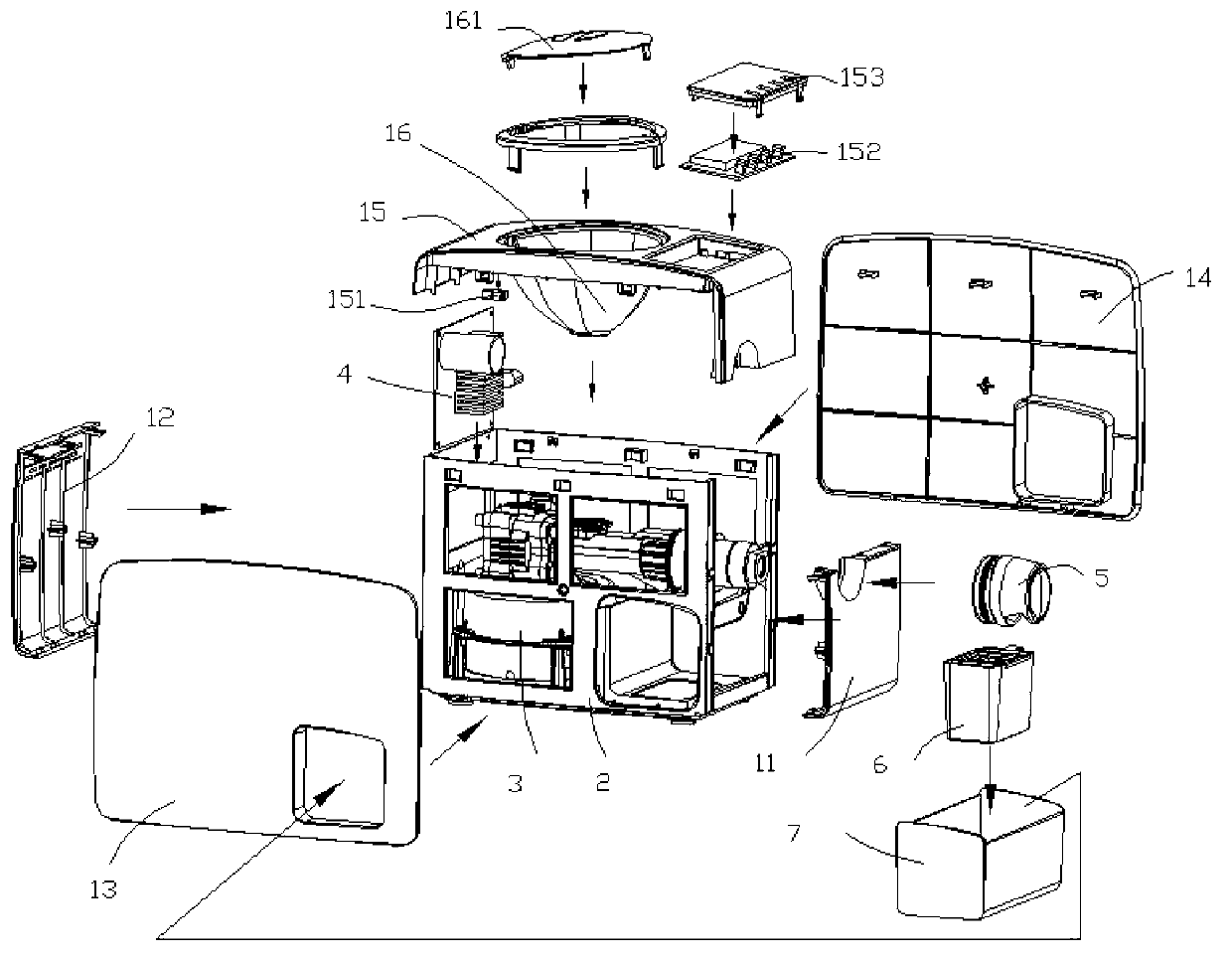

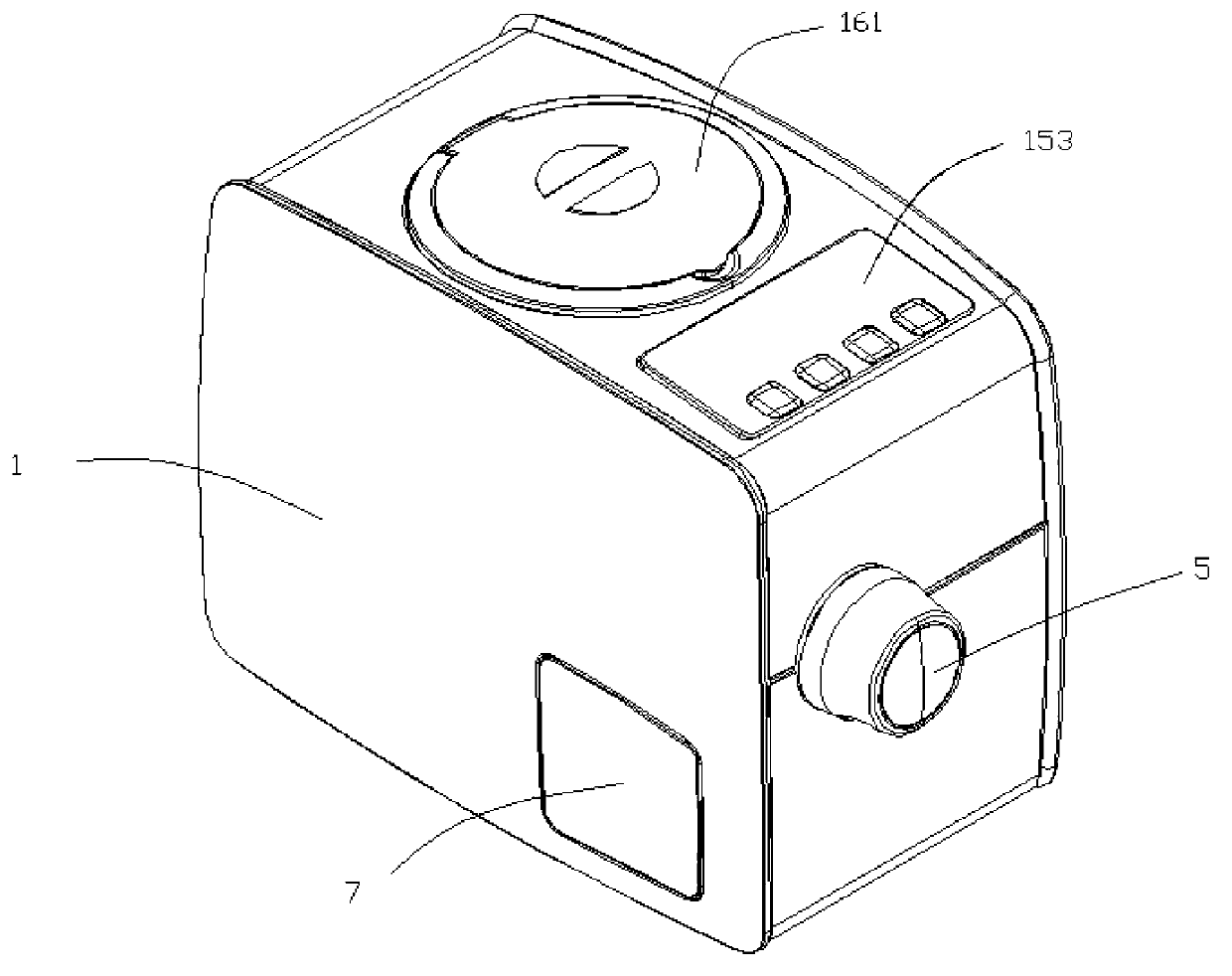

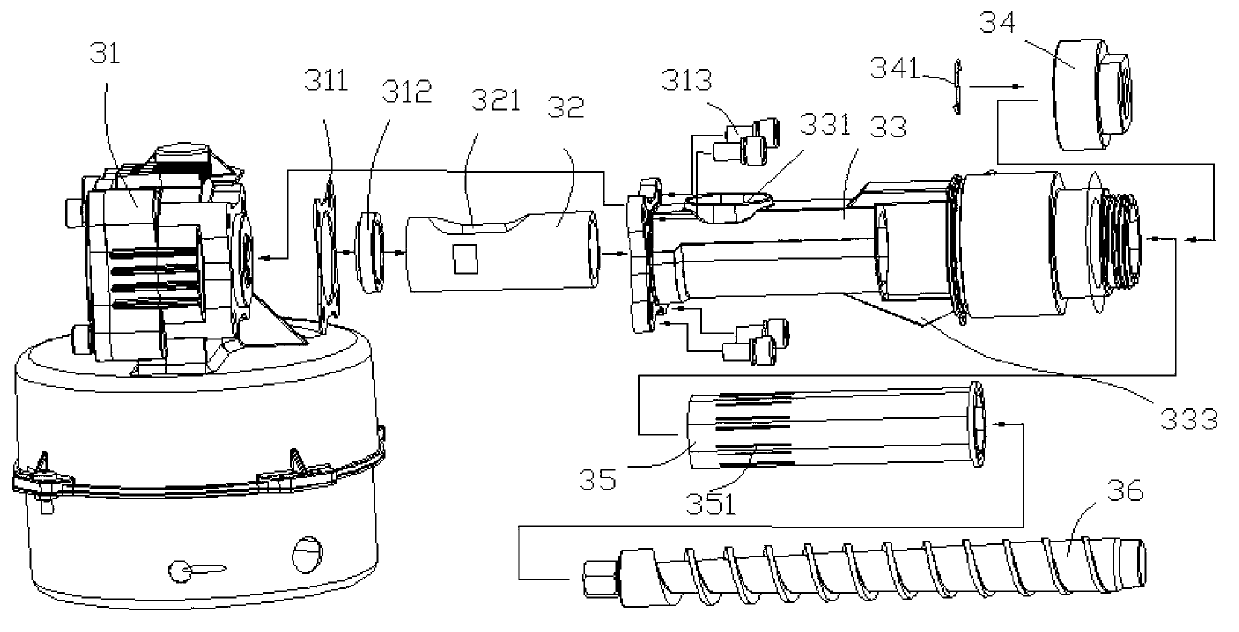

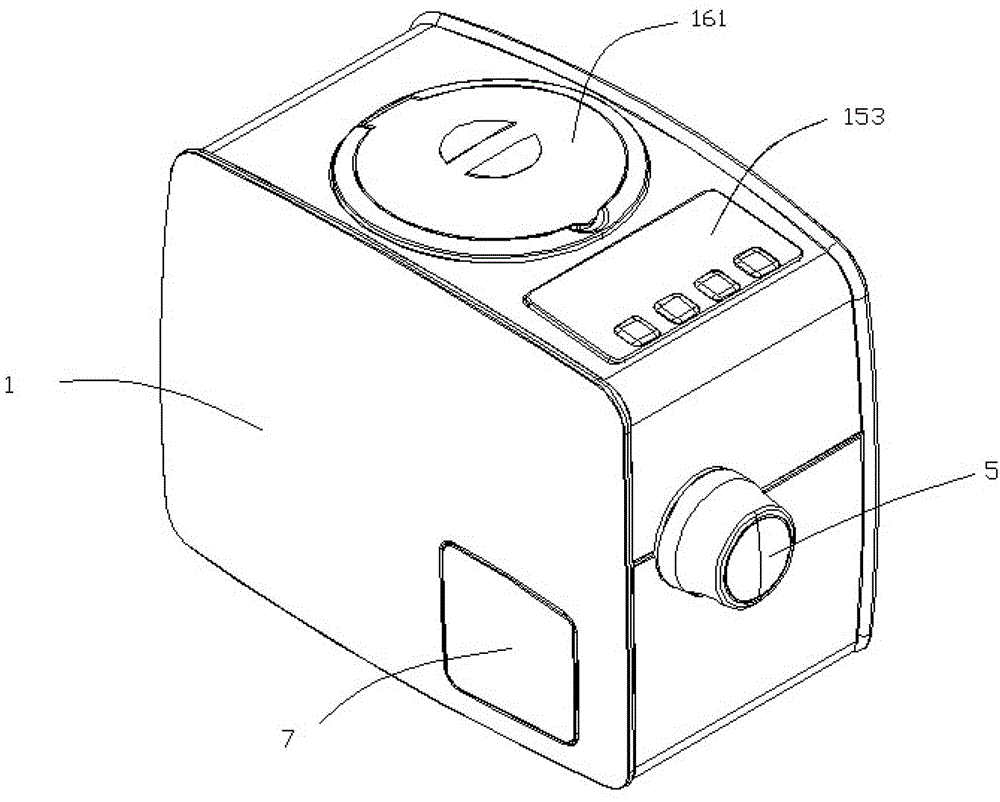

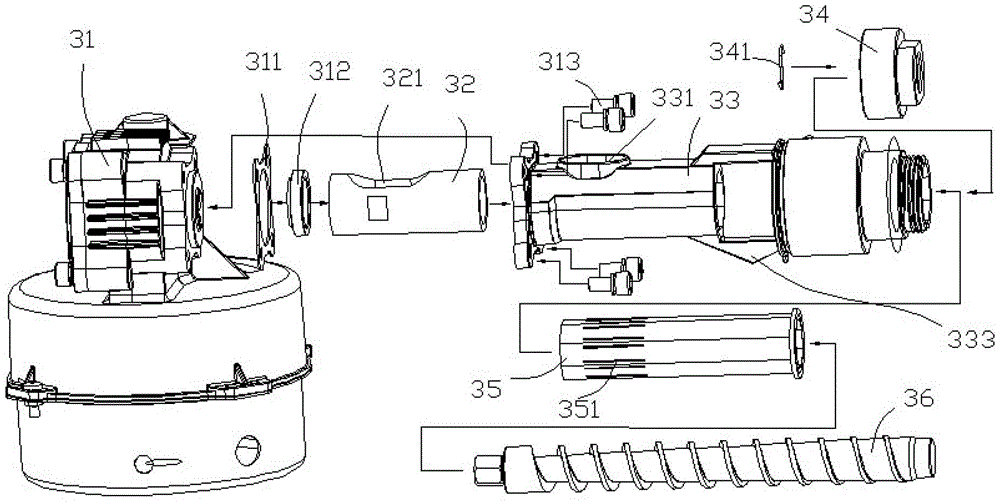

Oil-pressing and flour-milling machine

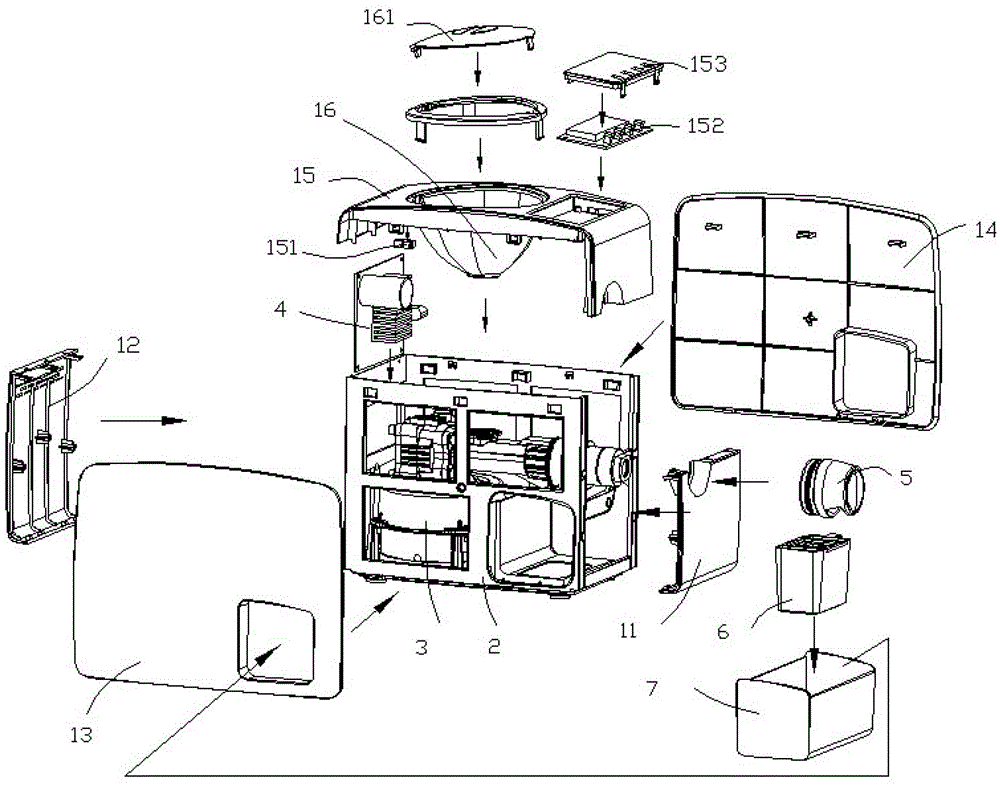

InactiveCN102990963ARealize oil extraction functionRealize the function of grindingPressesEngineeringMechanical engineering

The invention relates to an oil-pressing machine, and discloses an oil-pressing and flour-milling machine. The oil-pressing and flour-milling machine comprises an outer shell, an inner framework arranged in the outer shell, an oil-pressing machine body arranged in the inner framework, a motor and a program control board, wherein the program control board is used for controlling the motor to run, and the oil-pressing machine body comprises a pressing cavity, an oil-pressing shaft arranged in the pressing cavity, and an oil outlet tube sleeved on the oil-pressing shaft; one end of the pressing cavity is fixedly connected to the motor, and the other end of the pressing cavity is fixedly connected with an oil-pressing nut or a flour-milling nut; and a heat-isolating pad is arranged between the motor and the pressing cavity. According to the technical scheme disclosed by the invention, different functions can be realized by replacing the nut, an oil-pressing function is realized by replacing the nut to be the oil-pressing nut, and a flour-milling function is realized by replacing the nut to be the flour-milling nut.

Owner:YODA IND & TRADING

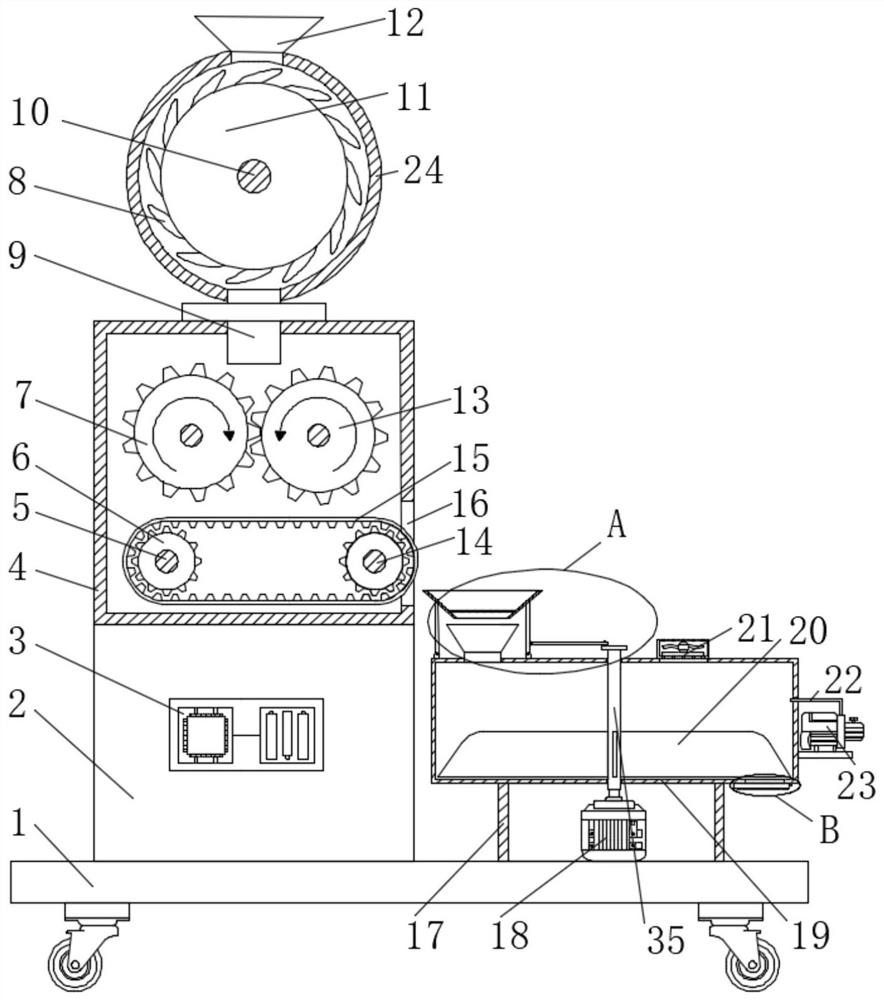

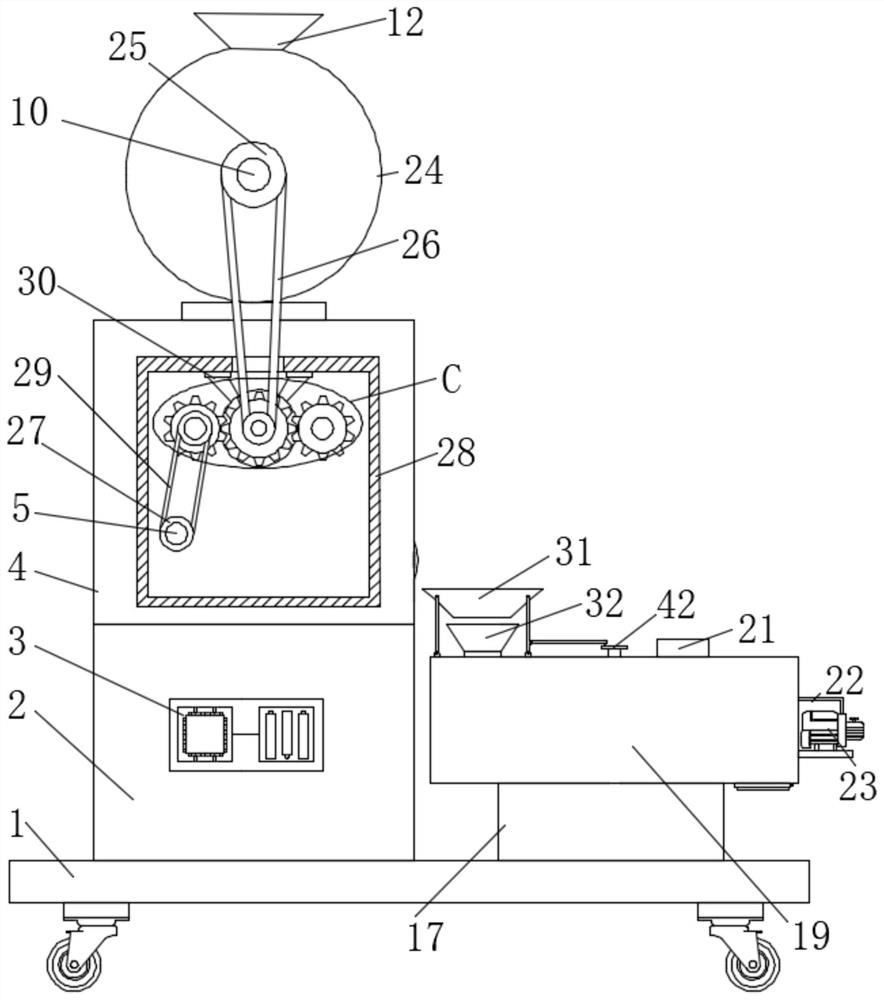

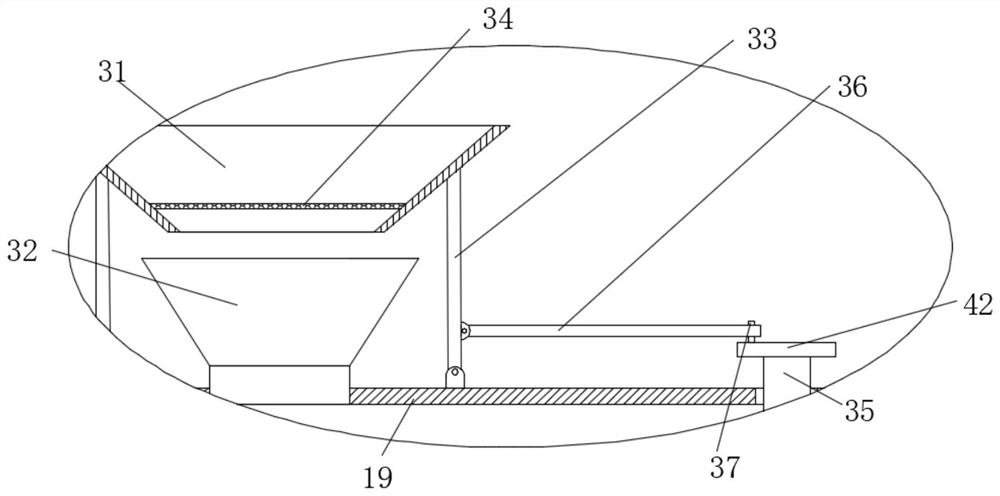

Graphene material grinding machining facility

The invention discloses a graphene material grinding machining facility. The graphene material grinding machining facility comprises base frames, a base plate and a shell. The base plate is fixed to the base frames, and the shell is installed on the base plate. A feeding unit is arranged on the outer wall of the shell, and a grinding unit is arranged inside the shell. A material collecting unit isarranged between the base frames, and a cleaning unit is arranged on the base frames. The feeding unit comprises a feeding mechanism and a flow control mechanism. The feeding mechanism comprises a collecting cover, a feeding pipeline and a feed nozzle. The feeding pipeline is installed above the shell through a stabilizing frame. The collecting cover is fixed to an end opening of the feeding pipeline. The feed nozzle is connected to the lower end of the feeding pipeline, and an opening of the feed nozzle is downward. The grinding unit comprises an upper grinding mechanism and a lower grindingmechanism. The graphene material grinding machining facility has the beneficial effects that according to the scheme, the real grinding facility which has the cleaning function is achieved on the basis that materials are extruded.

Owner:LINAN LEILUO PLASTIC FACTORY

Stirring equipment for feed production

InactiveCN112023801AAffect the uniformity of mixingAvoid wastingTransportation and packagingMixer accessoriesGear wheelNutrition

The invention relates to stirring equipment for feed production, which comprises a main body, a stirring device and two support blocks, and further comprises a grinding mechanism and a cleaning mechanism, the grinding mechanism comprises a fixed box, a filter screen, a feeding pipe, a discharging pipe and two grinding assemblies, and each grinding assembly comprises a bracket, a grinding roller, two rotating units and two cylinders; wherein the rotating unit comprises a first bearing, a rotating shaft, a rotating disc and a gear, the cleaning mechanism comprises a second bearing, a connectingshaft, a connecting disc, a torsion spring, a rotating rod, two cleaning assemblies and two pull wires, and each cleaning assembly comprises a material pump, a connecting box, a scraping plate, a connecting pipe and a connecting rod. The stirring equipment for feed production is capable of achieving grinding function through the ginding mechanism. The mixing uniformity of the feed is prevented from being influenced by caking of the powdery nutritional agent, so that the reliability of the equipment is improved, the function of cleaning the inner wall of the main body is realized through the cleaning mechanism, the feed is prevented from being adhered to the inner wall of the main body to influence the stirring and mixing quality, and the waste of the feed is also avoided.

Owner:王滨

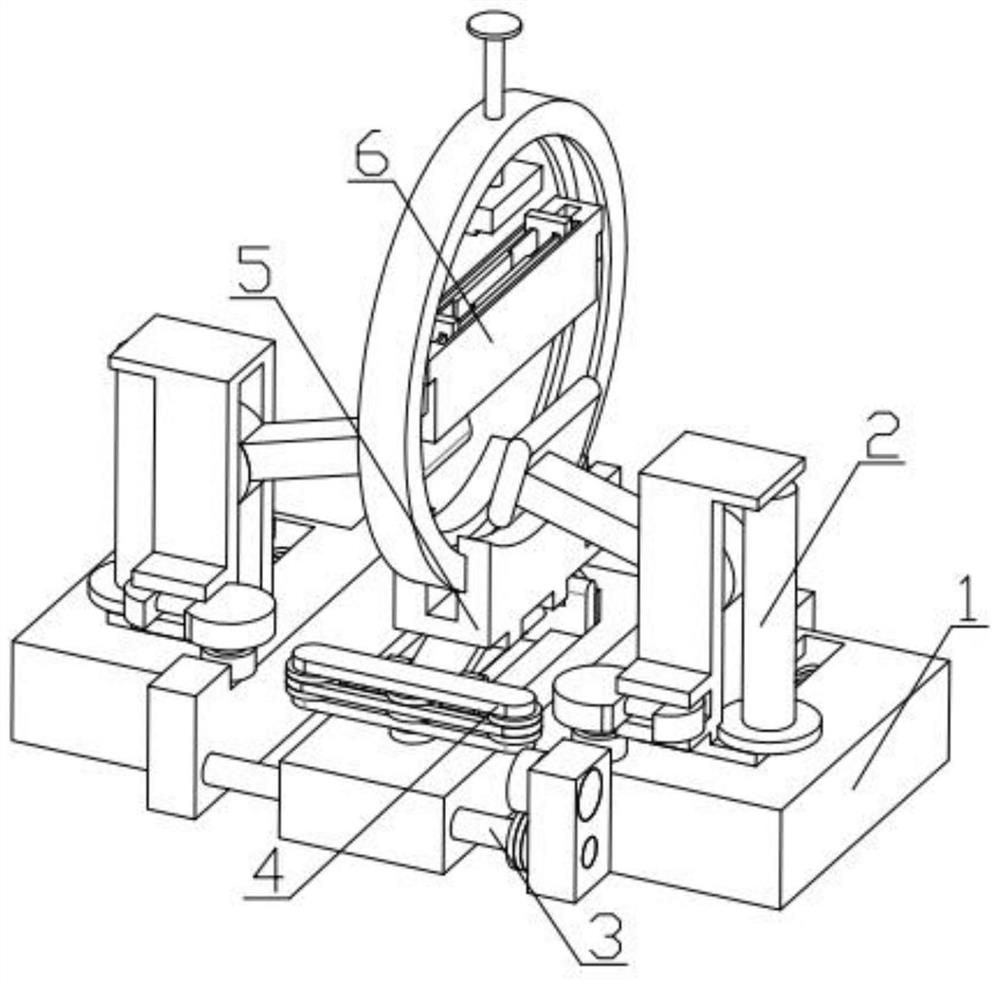

Vertical lathe grinding device

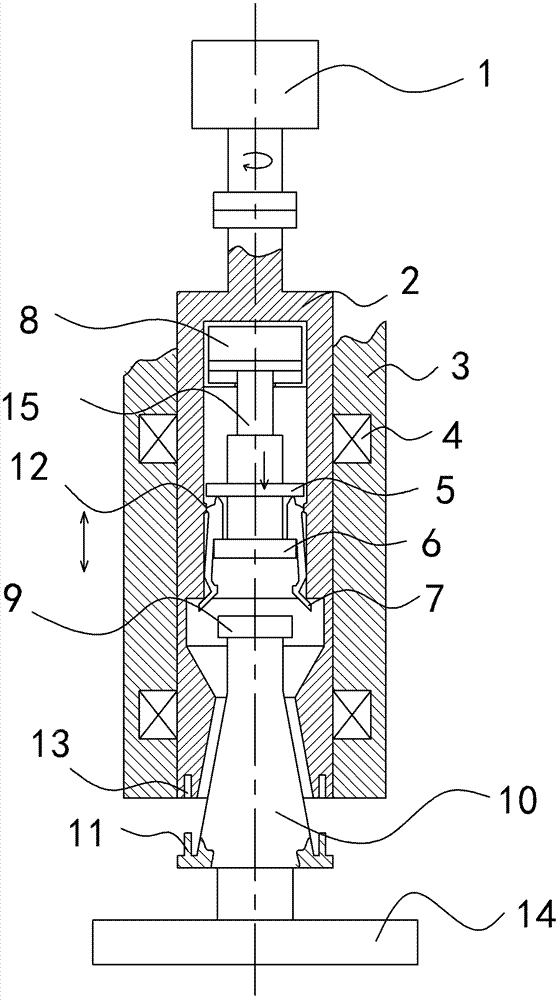

ActiveCN102248469BRealize the function of turningRealize the function of grindingGrinding machinesEngineeringGrinding wheel

The invention discloses a vertical lathe grinding device. A grinding function is developed on the basis of the original vertical lathe turning machining, so that the aim that the device has a plurality of functions is fulfilled. The device is characterized in that: a sliding post vertically arranged on a vertical lathe has a hollow structure; a rotating shaft is vertically arranged in a cavity ofthe hollow structure of the sliding post; the rotating shaft and the sliding post are rotationally supported through a bearing; a servo motor is arranged at the upper end of the rotating shaft, and is in transmission connection with the rotating shaft; the rotating shaft also has a hollow structure; a linear driving mechanism and a grasping device are arranged in a cavity of the hollow structure of the rotating shaft; a cutter frame is arranged at the bottom of the cavity of the hollow structure of the rotating shaft; and a grinding wheel is arranged at the lowest end of the cutter frame.

Owner:YOUJI MACHINE IND CHINA COMPANY

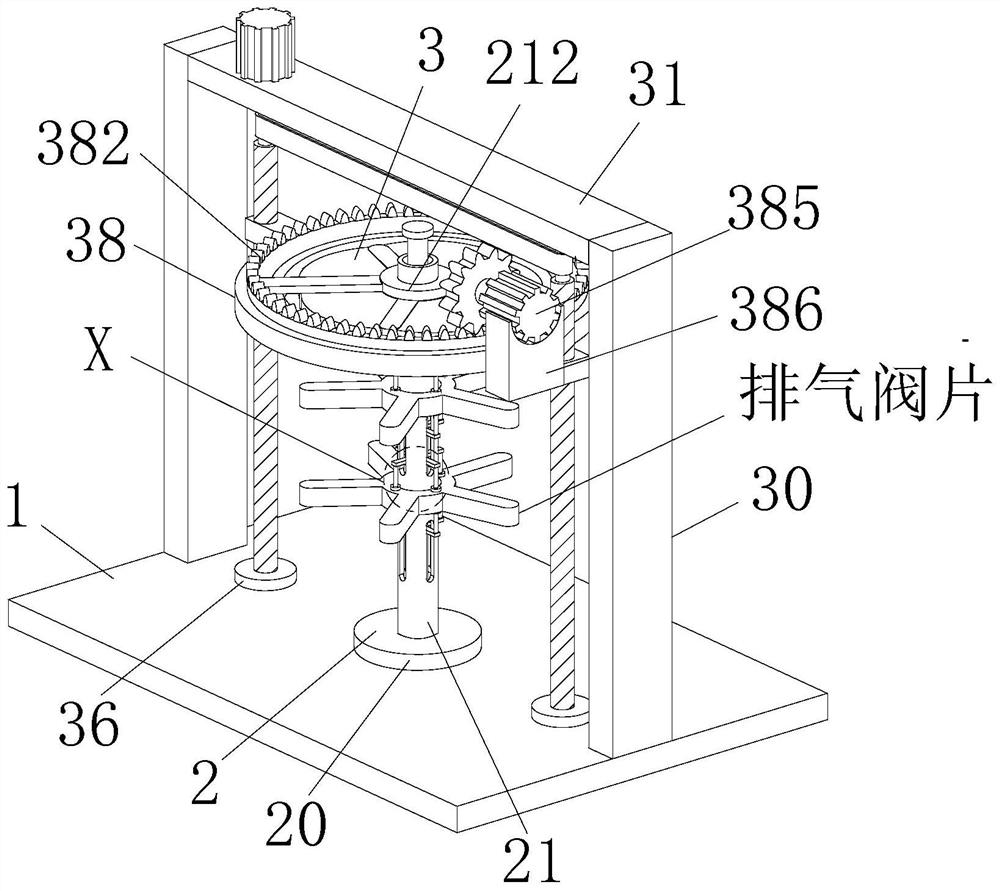

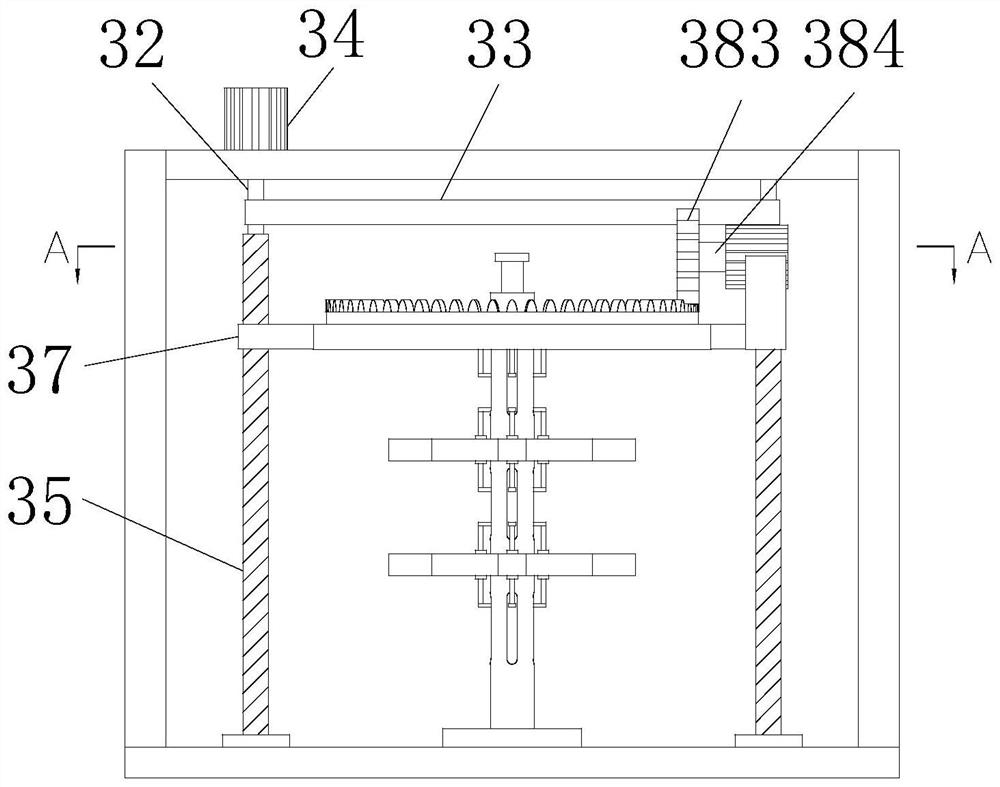

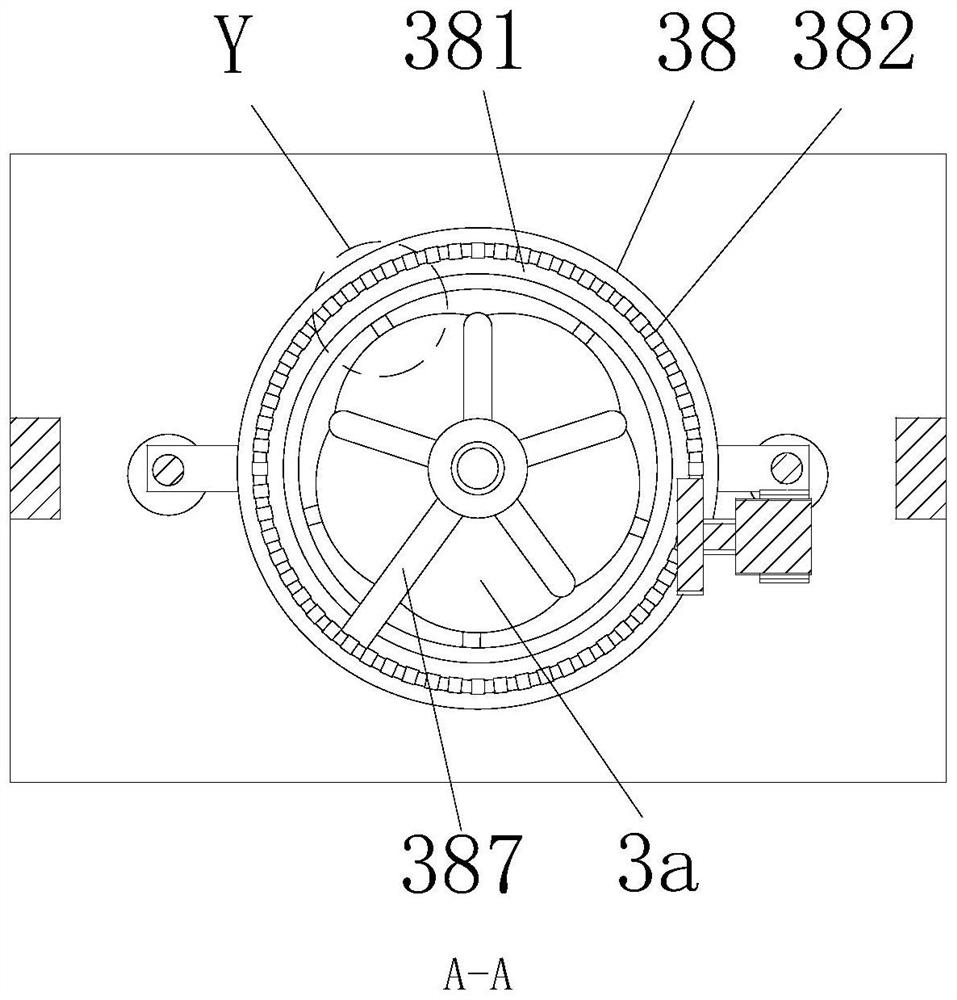

Forming finish machining system for exhaust valve plate assembly of air compressor

InactiveCN113001356AIncreased finishing rateEasy disassembly and assembly of the clamping unitGrinding drivesGrinding machinesPhysicsElectric machinery

The invention relates to a forming finish machining system for an exhaust valve plate assembly of an air compressor. The forming finish machining system comprises a base, a fixing mechanism and a grinding mechanism. The lower end of the base is connected with the existing ground, the fixing mechanism is installed at the upper end of the base, and the grinding mechanism is arranged at the upper end of the fixing mechanism. According to the forming finish machining system, through mutual cooperation of a first motor, a rotating rod and a circular ring sleeve, the circular ring sleeve drives a transverse rod to do synchronous linear opposite movement, the transverse rod drives a cylindrical rod and an extrusion block to do synchronous linear opposite movement, and therefore the function of clamping and fixing the air compressor exhaust valve plate assembly can be achieved, and the problem that the machining effect is poor due to the fact that the exhaust valve plate assembly of the air compressor deviates in the machining process is avoided.

Owner:盐城志焕网络科技有限公司

A kind of graphene material grinding processing equipment

The invention discloses a graphene material grinding and processing equipment, which comprises a bottom frame, a bottom plate and a shell, the bottom plate is fixed on the bottom frame, and the shell is placed on the bottom plate; the outer wall of the shell is provided with a feeding unit, and the inside of the shell is A grinding unit is provided; a material collection unit is provided between the bottom frames, and a cleaning unit is provided on the bottom frame; the feeding unit is composed of a feeding mechanism and a flow control mechanism; the feeding mechanism , which includes: a collection cover, a feed pipe and a feed nozzle; the feed pipe is placed above the shell through a stabilizer, the collection cover is fixed at the port of the feed pipe, the feed nozzle is connected to the lower end of the feed pipe, and The opening of the feeding nozzle is downward; the grinding unit is composed of an upper grinding mechanism and a lower grinding structure. The beneficial effect of the present invention is that the gist of the present case is to provide a real grinding device with cleaning and on the basis of extruding materials.

Owner:TAIZHOU LAI & KE INTELLIGENT TECH CO LTD

A teaching abacus bead punching device

ActiveCN108297189BRealize the function of punchingRealize lifting functionEdge grinding machinesStationary drilling machinesPunchingStructural engineering

The invention relates to punching equipment, in particular to punching equipment of a teaching abacus bead. The invention aims to provide the punching equipment of the teaching abacus bead which is convenient to use and easy to operate. In order to solve the technical problem, the invention provides the punching equipment of the teaching abacus bead. The equipment comprises a base, first supports,a support plate, a first nut, a first screw rod, a first rotary plate, a first sliding rail, a first sliding block, a first clamp, a second clamp and the like, wherein two first supports are fixedlyconnected to the base, the supporting plate is arranged on the two first supports, and the first nut is fixedly connected to the left side of the upper portion of the base, the first screw rod is matched in the first nut, and the first rotary plate is fixedly connected to the left end of the first screw rod. According to the equipment, the function of punching the abacus bead is achieved, not onlythe function of lifting the supporting plate is achieved, but also the function of grinding the abacus bead with punched hole is achieved.

Owner:辛秋萍

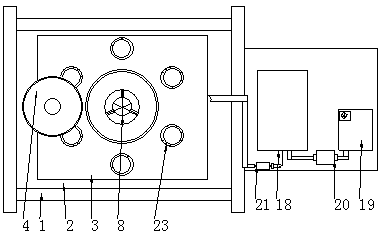

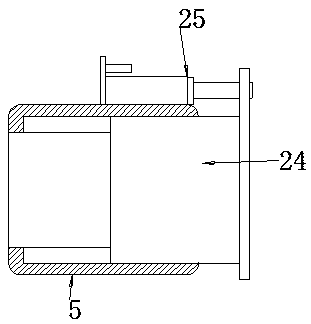

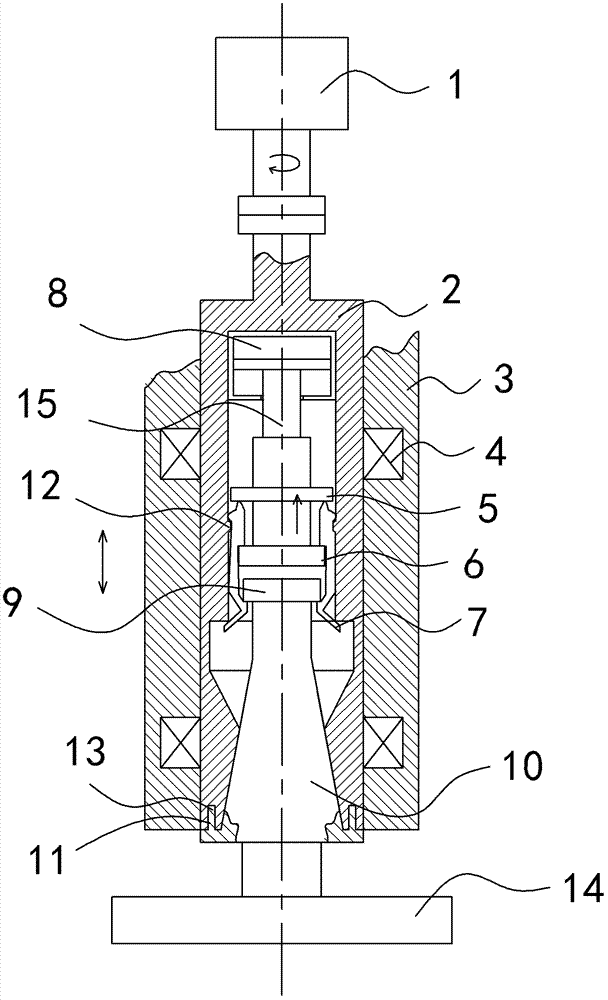

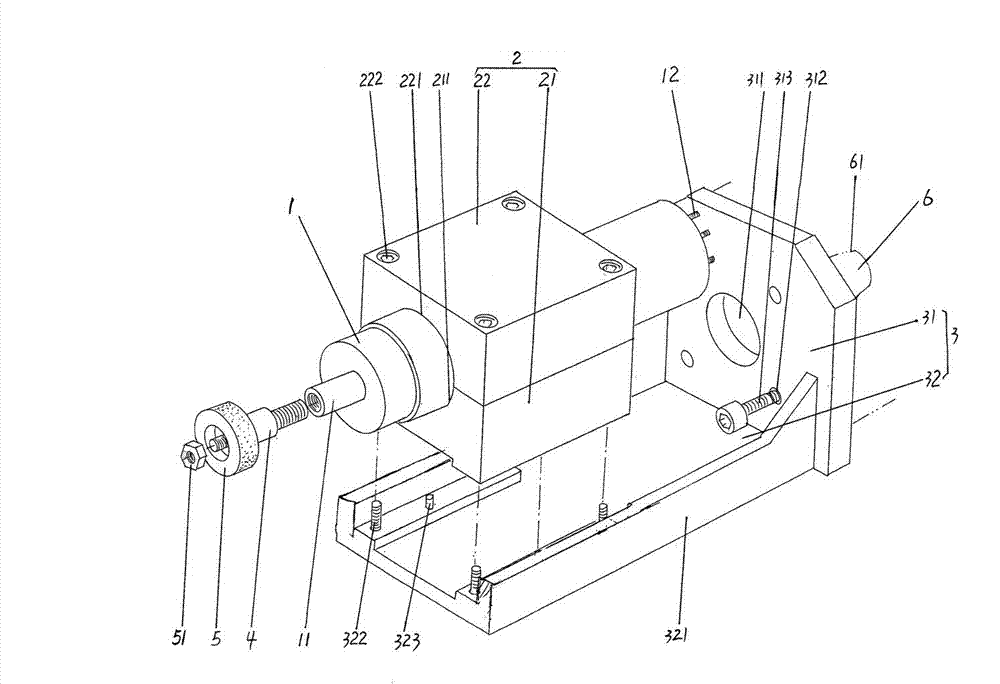

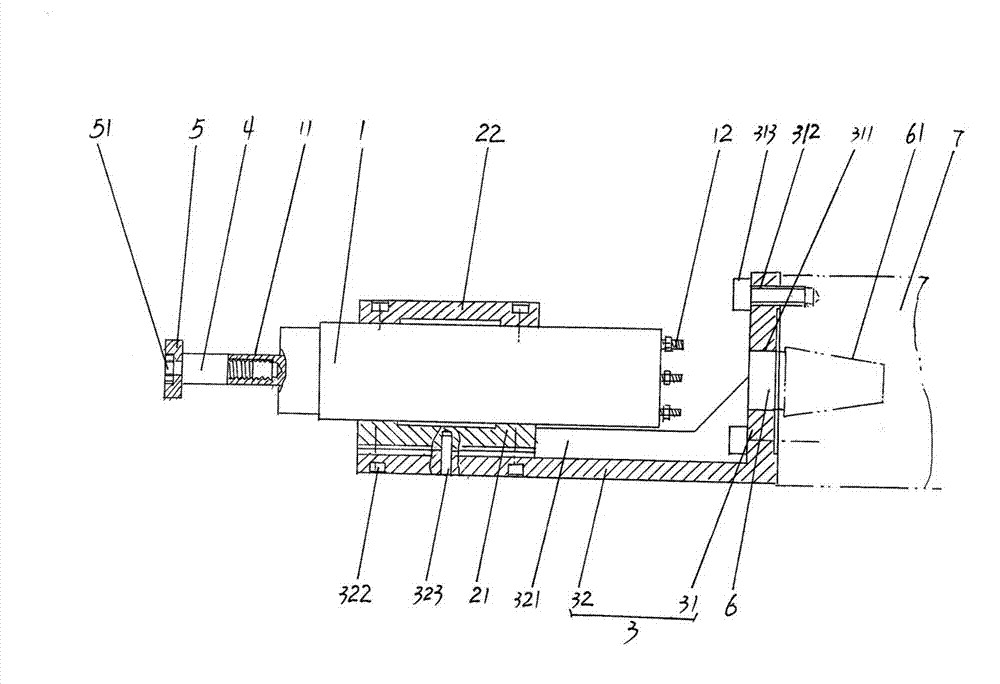

High-speed grinding head device suitable for numerical control boring and milling machine

InactiveCN103111938AGuaranteed grinding qualityRealize the function of grindingGrinding machine componentsElectric machineryHigh-speed grinding

A high-speed grinding head device suitable for numerical control boring and milling machines belongs to the technical field of grinding tools. The high-speed grinding head device comprises an electric spindle, a fixing mechanism, a support, a grinding wheel connecting rod and a grinding wheel. The support comprises an assembling part matched with a machine tool spindle and a support part matched with the fixing mechanism. The assembling part is located at one end of the support part and perpendicular to the same. The fixing mechanism is mounted on the support part. A through hole penetrating from left to right is reserved on the fixing mechanism. The electric spindle is mounted in the through hole and perpendicular to the assembling part. A positioning hole is reserved on the assembling part, the center of the positioning hole are on the same axis of the center of the electric spindle, an output end of the electric spindle is connected to one end of the grinding wheel connecting rod, and the other end of the grinding wheel connecting rod is fixed with the grinding wheel. Grinding of local special-shaped surfaces by medium and large numerical control boring and milling machines with spindle motor power larger than 30KW, and grinding quality is guaranteed.

Owner:苏州力强机械制造有限公司

Multi-axis automatic grinding machine

The invention relates to a grinding machine, in particular to an automatic multiple-shaft grinding machine and belongs to the technical field of grinding machines. The automatic multiple-shaft grinding machine comprises a grinding machine tool body, wherein a workpiece positioning tray is arranged at the left end of the grinding machine tool body. A workpiece clamping component is fixed to the workpiece positioning tray, multiple workpiece clamping cavities are formed in the workpiece clamping component, and one part can be clamped in each workpiece clamping cavity. The number of grinding heads is equal to the number of the workpiece clamping cavities, one workpiece clamping cavity is correspondingly arranged on the axis of each grinding head, and each grinding head conducts reciprocating grinding on the workpiece in the correspondingly formed workpiece clamping cavity. The automatic multiple-shaft grinding machine adopts the multiple-shaft grinding heads and can simultaneously conduct automatic grinding on the outer circles and inner holes of multiple parts, machining efficiency is improved, a crankshaft connecting rod mechanism is adopted, and a multiple-shaft radial and axial automatic grinding function is achieved.

Owner:鹰普航空科技有限公司

Oil-pressing and flour-milling machine

InactiveCN102990963BRealize oil extraction functionRealize the function of grindingPressesMechanical engineeringProgram control

The invention relates to an oil-pressing machine, and discloses an oil-pressing and flour-milling machine. The oil-pressing and flour-milling machine comprises an outer shell, an inner framework arranged in the outer shell, an oil-pressing machine body arranged in the inner framework, a motor and a program control board, wherein the program control board is used for controlling the motor to run, and the oil-pressing machine body comprises a pressing cavity, an oil-pressing shaft arranged in the pressing cavity, and an oil outlet tube sleeved on the oil-pressing shaft; one end of the pressing cavity is fixedly connected to the motor, and the other end of the pressing cavity is fixedly connected with an oil-pressing nut or a flour-milling nut; and a heat-isolating pad is arranged between the motor and the pressing cavity. According to the technical scheme disclosed by the invention, different functions can be realized by replacing the nut, an oil-pressing function is realized by replacing the nut to be the oil-pressing nut, and a flour-milling function is realized by replacing the nut to be the flour-milling nut.

Owner:YODA IND & TRADING

A metal wrench forming finishing device

ActiveCN113386023BRealize the clamping functionEffective sandingGrinding carriagesGrinding machinesWrenchPhysics

The invention relates to the technical field of metal wrench finishing, in particular to a hardware wrench forming and finishing device, which includes a workbench, a clamping mechanism and a grinding mechanism, and the workbench is equipped with the clamping mechanism and the grinding mechanism. The present invention installs the matching blocks in a detachable manner so as to quickly replace the matching blocks of different specifications, realizes the function of clamping tire wrenches of different specifications, and improves the practicability of the present invention; The grinding block and the No. 2 grinding block have the function of keeping fit with the outer surface of the wrench connecting rod and the outer surface of the wrench end respectively, so as to avoid the problem of poor grinding effect caused by the uneven surface of the tire wrench.

Owner:江苏优霸五金工具有限公司

A grinding equipment dedicated to biological experiments

ActiveCN108452914BRealize the function of grindingRealize the stirring functionRotary stirring mixersTransportation and packagingExperimental drugEngineering

The invention relates to a grinding device, in particular to a grinding device specially used for biological experiments. The technical problem to be solved by the present invention is to provide a time-saving, labor-saving and uniform grinding equipment specially used for biological experiment drug grinding. In order to solve the above-mentioned technical problems, the present invention provides such a pharmaceutical grinding equipment dedicated to biological experiments, which includes a base, a first collection box, a first bracket, a second bracket, a first slide rail, a first slider, a first Connecting rod, second connecting rod, grinding block, first fixed plate, etc.; the first collection box is placed above the base, the first bracket is fixedly connected to the upper right side of the base, and the left side of the first bracket is fixedly connected to There is a second bracket, and the left part of the second bracket is provided with a first through hole. The invention realizes the function of grinding the medicine, not only realizes the function of quickly grinding the medicine, but also realizes the function of stirring the medicine.

Owner:浙江玉安康瑞生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com