Pipe excircle grinding device for industrial production

A technology for the outer circumference of pipes and pipes, which is used in grinding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of not being able to grind the clamping position and pinching the grinding surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

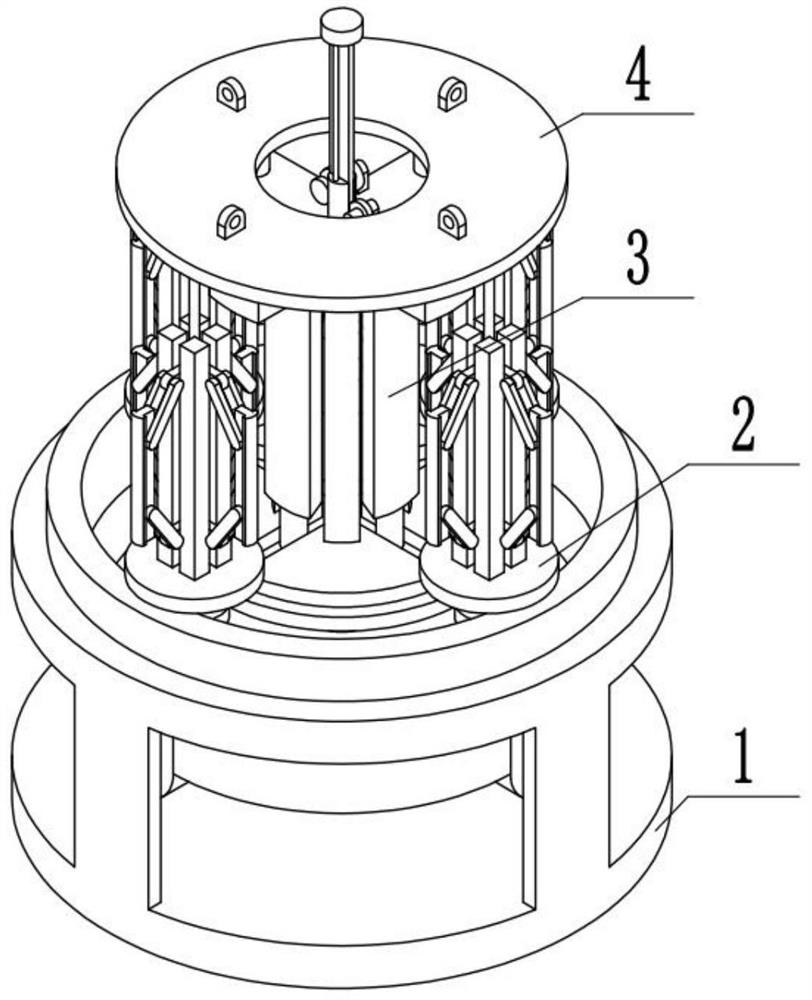

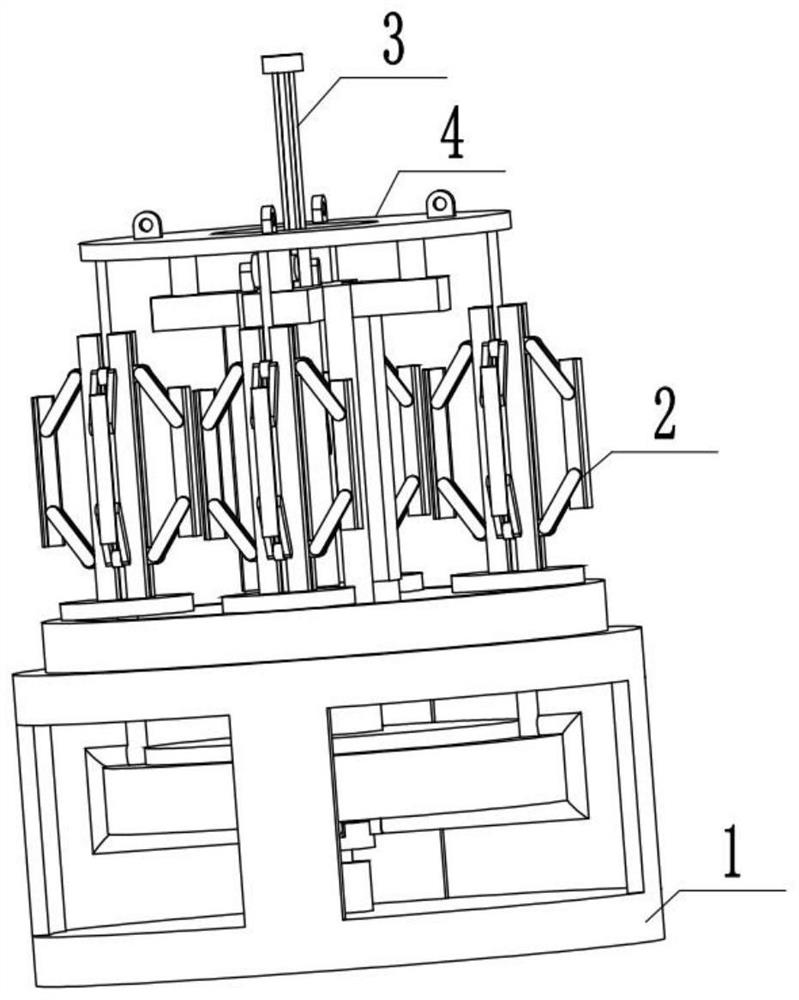

[0036] Combine below figure 1 , 2 Description of this embodiment, a pipe cylindrical grinding device for industrial production, including a fixed base 1, a pipe fixing device 2, a pipe grinding device 3 and an upper cover 4, the fixed base 1 is fixedly installed with a pipe fixing device 2. There are multiple pipe fixing devices 2, the pipe fixing device 2 is installed on the pipe grinding device 3, and the upper cover plate 4 is installed on the pipe fixing device 2.

specific Embodiment approach 2

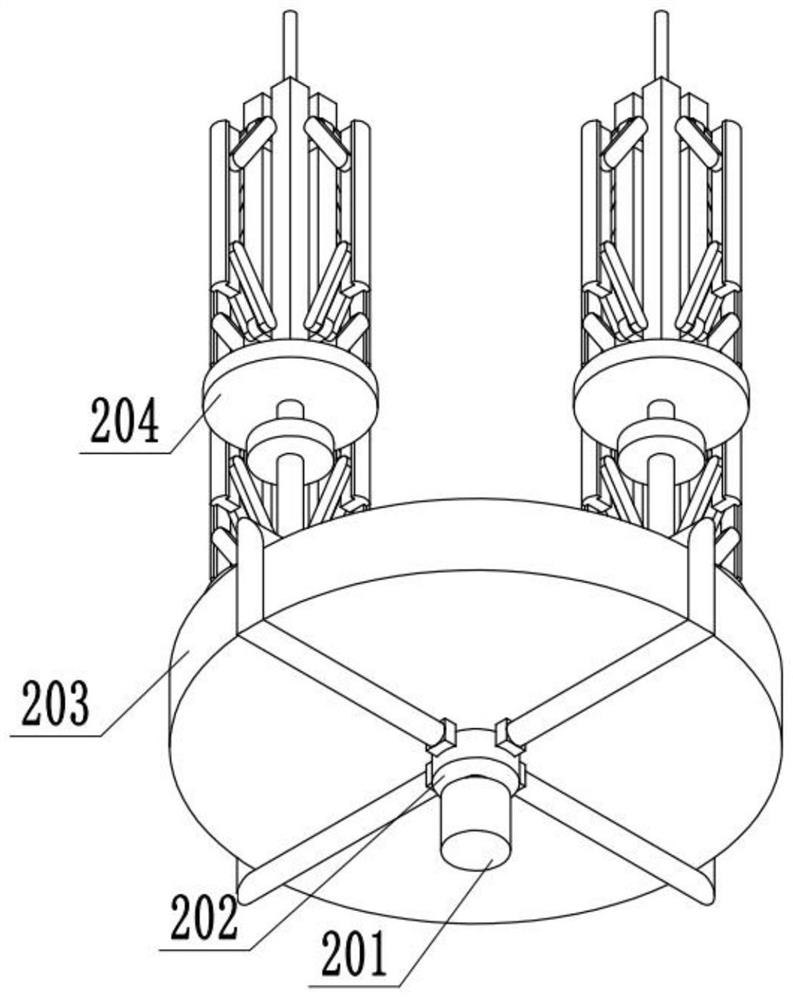

[0038] Combine below image 3 , 4 , 5, 6 illustrate this embodiment, and this embodiment will further explain Embodiment 1. The pipe fixing device 2 includes a power motor A201, a driving gear 202, a fixed chassis 203, and a pipe fixing mechanism 204. The power motor A201 is fixedly installed on On the fixed chassis 1, the output end of the power motor A201 is equipped with a drive gear 202, the drive gear 202 is connected with the pipe fixing mechanism 204, and the pipe fixing mechanism 204 is slidably installed on the fixed chassis 203;

[0039] The fixed chassis 203 includes an arc tooth block 205, a drive crankshaft 206, a drive rod 207, a feed gear 208, a pipe placement plate 209, a field-shaped mounting frame 210, a cross thread block A211, a connecting rod A212, and a top clamping block for fixing Frame 213, top tight block 214, connecting rod B215, cross thread block B216, two-way threaded screw rod 217, arc tooth block 205 is meshed with drive gear 202 by tooth, is f...

specific Embodiment approach 3

[0041] Combine below Figure 7 , 8 , 9, 10, 11, 12, 13 illustrate this embodiment, and this embodiment will further explain Embodiment 1. The pipe grinding device 3 includes a fixed bottom column 301, a fixed tooth plate 302, a cross chute A303, and a grinding plate 304, fixed cross 305, positioning rod 306, grinding adjustment mechanism 307, the top of the fixed bottom column 301 is fixedly installed with a fixed tooth plate 302, the fixed tooth plate 302 and the feed gear 208 are meshed through teeth, and the cross chute A303 is arranged on the fixed On the toothed disc 302, the two ends of the grinding plate 304 are respectively installed in the cross chute A303 provided on the fixed toothed disc 302 and on the fixed cross 305, the fixed cross 305 is fixedly installed on the fixed toothed disc 302, and the positioning rod 306 is fixedly installed on the On the fixed cross 305, a grinding plate 304 is movably installed on the grinding adjustment mechanism 307, and the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com