Graphene material grinding machining facility

A technology of grinding and processing graphene, applied in the fields of cocoa, grain processing, food science, etc., can solve the problems of trouble, inconvenient cleaning, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

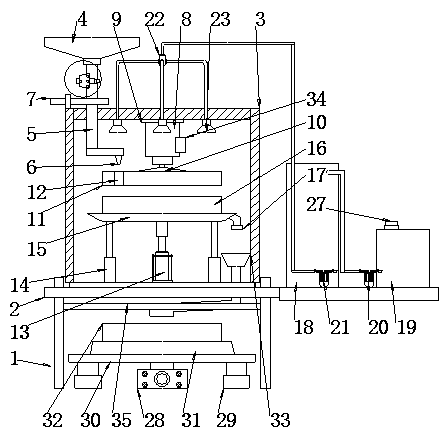

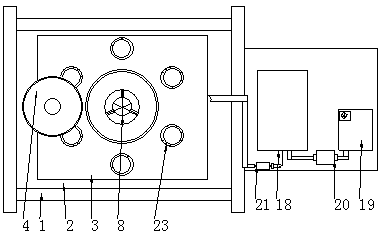

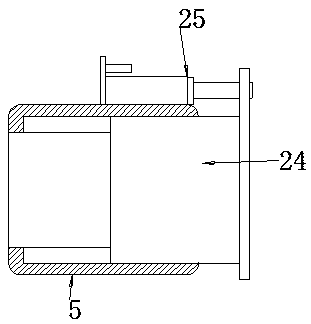

[0052] Embodiment: firstly, graphene enters manually through the feeding pipeline 5 communicated with the collection cover 4, and after the electric push rod 25 pushes the baffle plate 24 to open, the graphene enters the feeding nozzle 6, and throws the feeding nozzle 6

[0053] It is located above the feeding port of the upper grinding disc 11 and falls onto the lower grinding disc 16 through the feeding port. The hydraulic cylinder 13 on the bottom plate 2 is controlled to push the lower grinding disc 16 up, and the lower grinding disc 16 will contact the upper grinding disc 11. Approaching, thereby realizing the extruding to graphene, after finishing initial extruding, be positioned at the driving motor 8 on the inner wall of casing 3 work, driving motor 8 drives upper grinding disc 11 to rotate, and upper grinding disc 11 and lower grinding disc 16 pair graphite Graphene is ground again, and the graphene powder will generate centrifugal force with the rotation of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com