Metal surface polishing device

A metal surface and equipment technology, which is applied in the field of metal surface grinding equipment, can solve the problems of hidden dangers in installation, inconvenient use for users, and no setting to prevent cylindrical metal, so as to achieve the effect of strengthening stability and preventing hands from falling out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, features and effects of the present invention, the following examples are exemplified and described in detail with reference to the accompanying drawings.

[0023] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

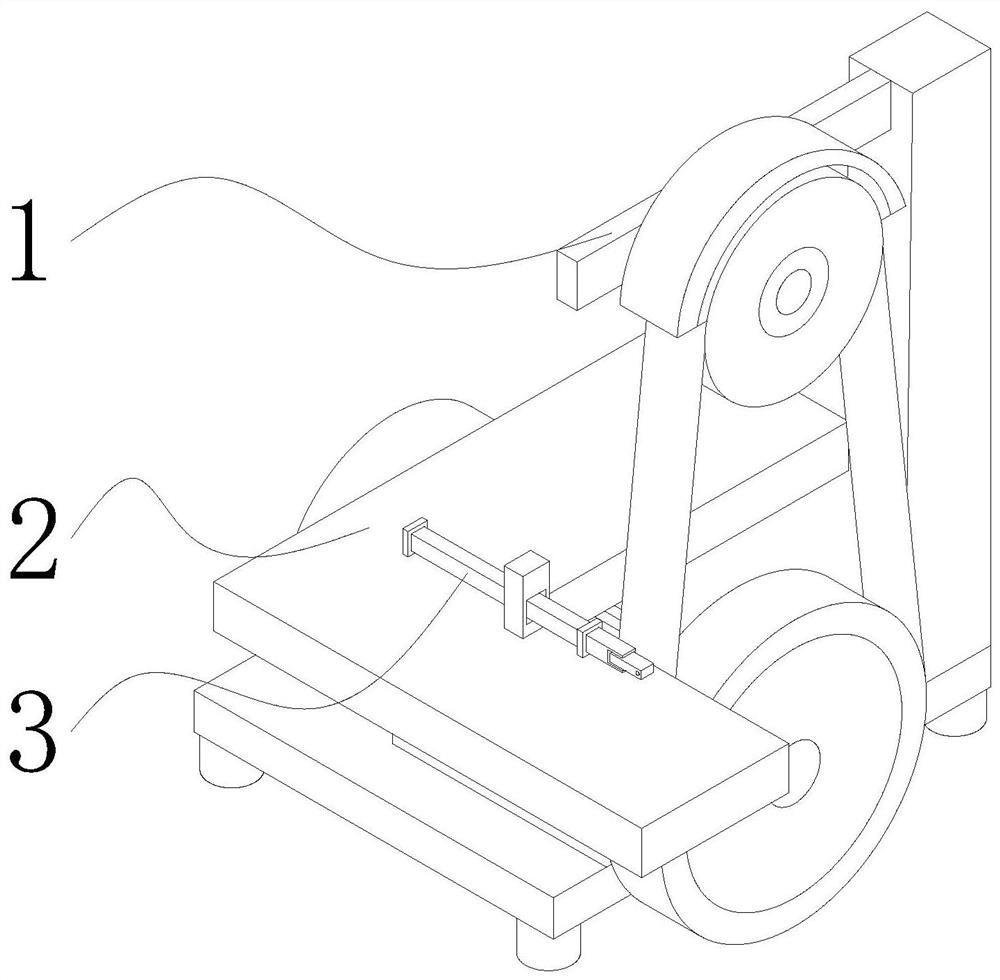

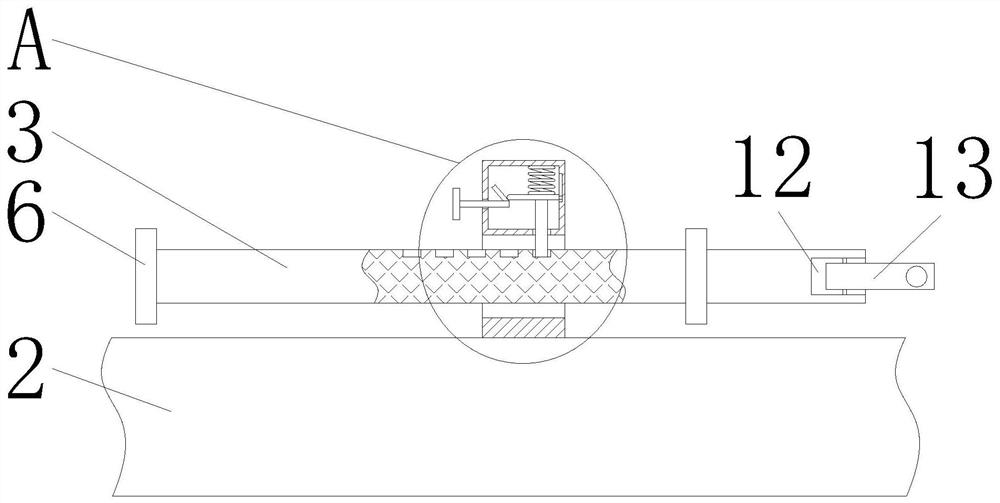

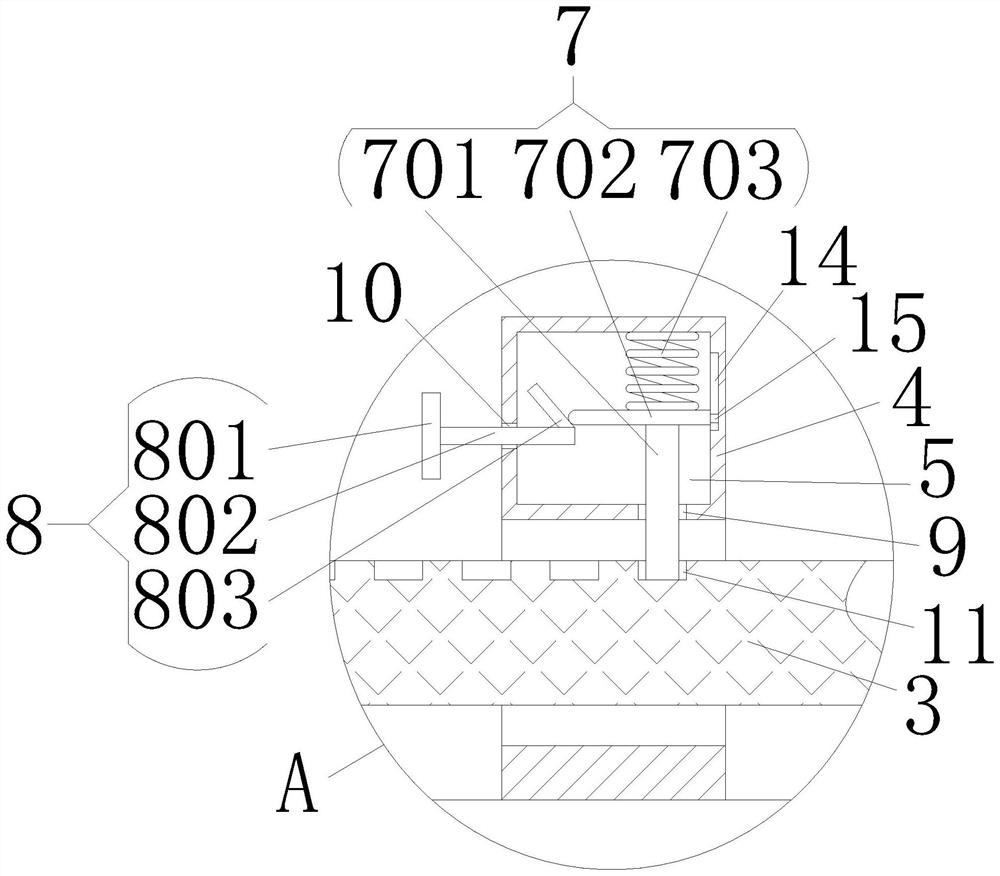

[0024] Such as Figure 1 to Figure 3 As shown, a kind of metal surface grinding equipment provided by the embodiment of the present invention includes a main body 1, a placing plate 2 is arranged on the left side of the main body 1, an adjusting rod 3 is arranged on the top of the placing plate 2, and the left side of the adjusting rod 3 is provided with a limited Position block 4, the top of the limit block 4 is provided with an adjustment groove 5, the left side of the adjustment rod 3 passes through the limit block 4 and extends to the left side of the limit block 4, and the surface of the adjustment rod 3 is fixedly connected with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap