Quick locking mechanism, mounting device and automobile

A locking mechanism, fast technology, applied in the direction of electric vehicles, power devices, electric power devices, etc., can solve the problems of easy deformation, stress concentration, etc., and achieve the effect of fast limit installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

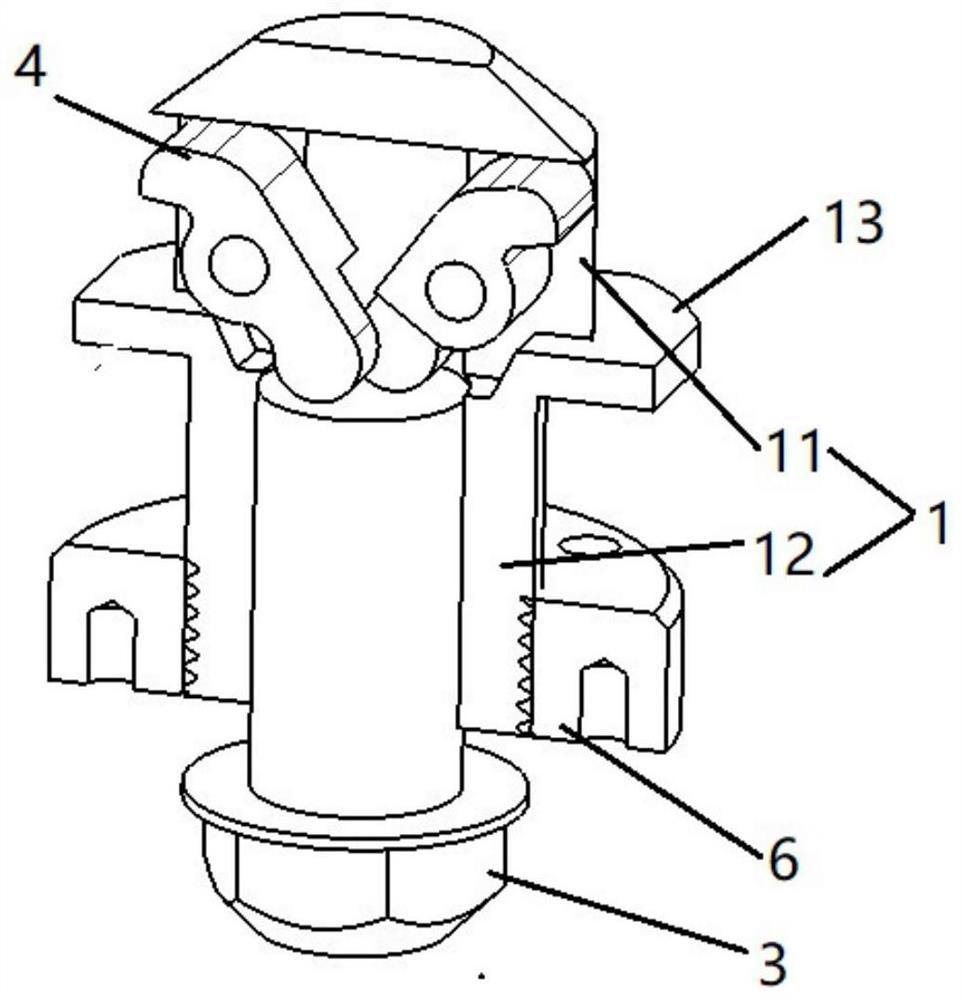

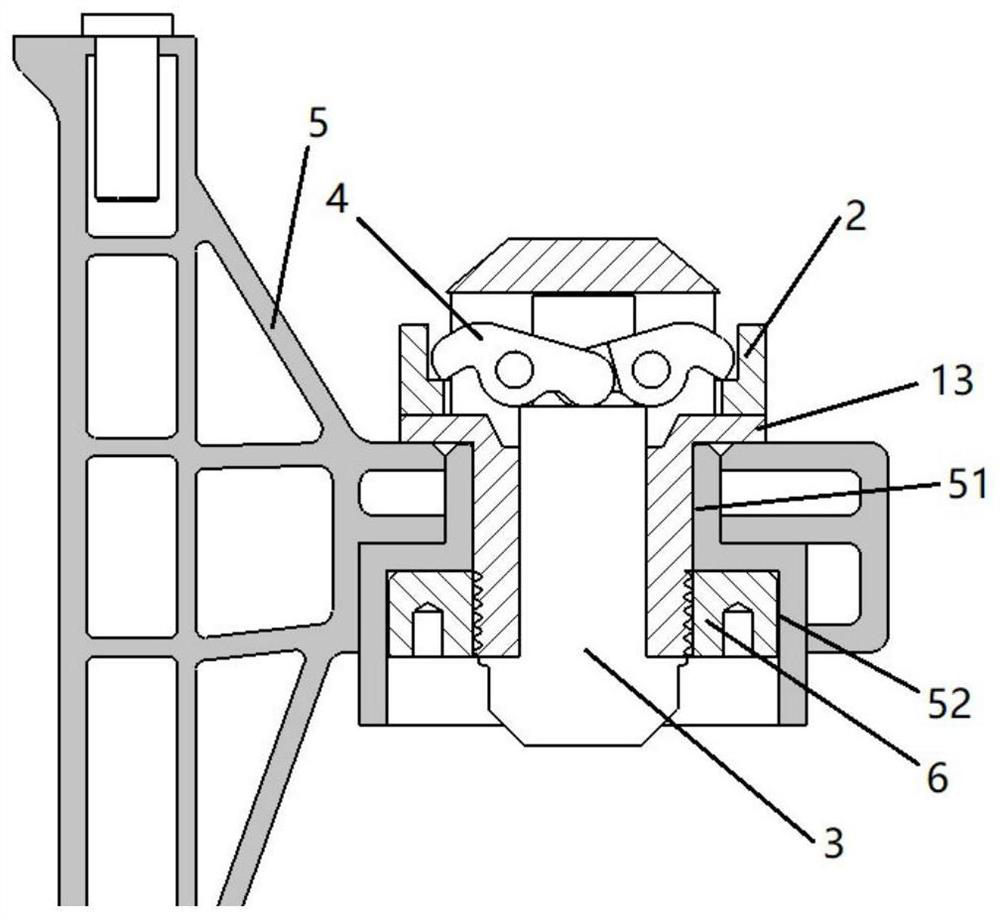

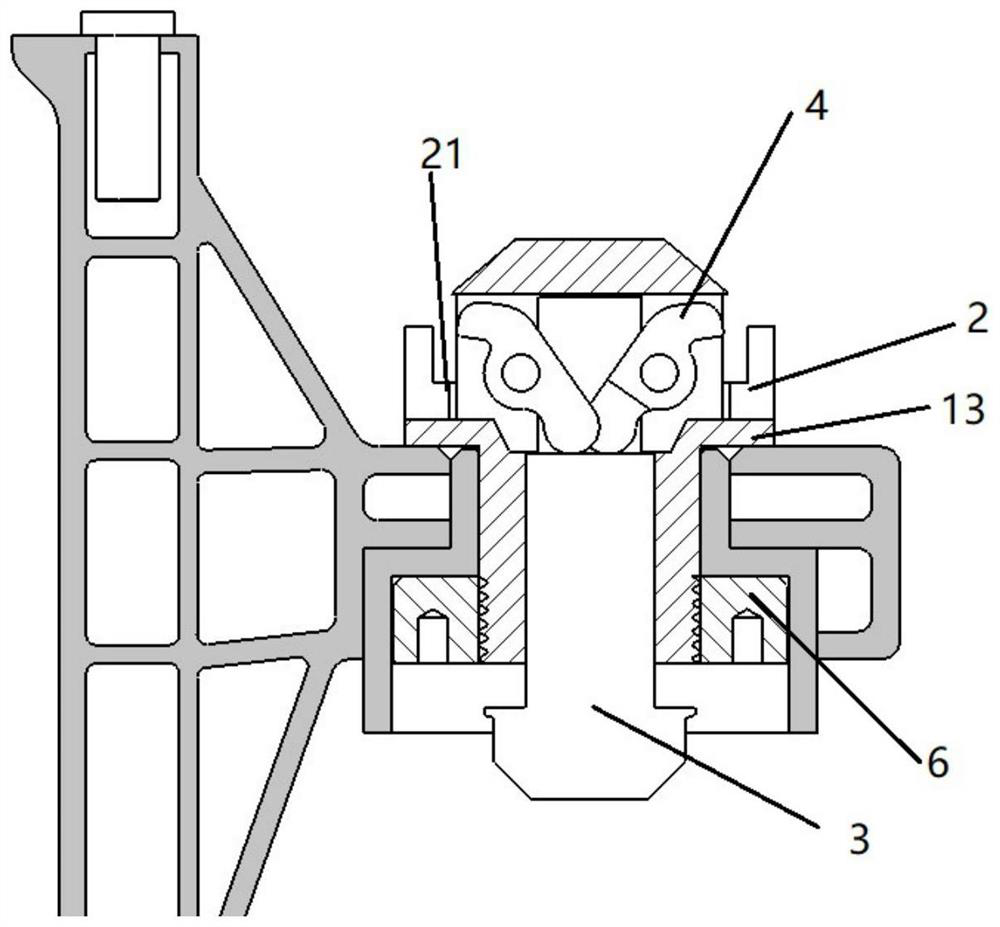

[0031] like Figure 1-4 As shown, it is a quick locking mechanism, including a locking housing 1 , a locking connector 2 , a jacking device 3 and a locking member 4 ; wherein the locking housing 1 is installed on a mounting beam 5 .

[0032] The locking piece 4 and the locking housing 1 are hinged through the hinge shaft 4, wherein a return spring, such as a coil spring, etc. is provided on the hinge shaft. Reset is also possible. The locking part 4 is provided with a locking end 41 and a driving end 42 on both sides of the hinge point. The locking housing 1 is a hollow structure jacking device 3, which is specifically a locking bolt and is at least partly arranged in the locking housing. The locking housing 1 It has a locking part 11 and a connecting part 12. The locking part 4 is hinged to the locking part 11. The jacking device 3 is connected to the connecting part 12. The jacking device 3 is a locking bolt. The inner cavity of the connecting part 12 has a The thread matc...

Embodiment 2

[0037] The difference from Embodiment 1 is that the jacking device is a piston rod, which is driven by a pneumatic device and can move axially relative to the locking housing 1. Compared with Embodiment 1, this embodiment uses a piston rod as a reciprocating The locking and releasing driving mechanism makes the driving method more rapid and direct.

[0038] Through the above specific embodiments, the following technical effects are achieved:

[0039] (1) The locking piece is hinged to the locking shell, and the rotation of the locking piece relative to the locking shell is controlled through the cooperation of the jacking device to realize locking and disengagement. The cooperation of the jacking device and the locking piece replaces the original locking method of the small ball on the top of the big ball, and there will be no technical problems in the original technology that cause deformation due to excessive concentration of stress due to the contact and cooperation between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com