A car seat storage device and working method

A technology for storage equipment and car seats, which is applied in storage devices, transportation and packaging, etc., can solve the problem of difficulty in ensuring the efficiency of finished product seats in the warehouse and warehouse, waste of inventory warehousing and subcontracting manpower, and complicated processes for accessing goods. and other problems, to avoid the risk of bumping the finished seat, the design is reasonable, and the practicability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

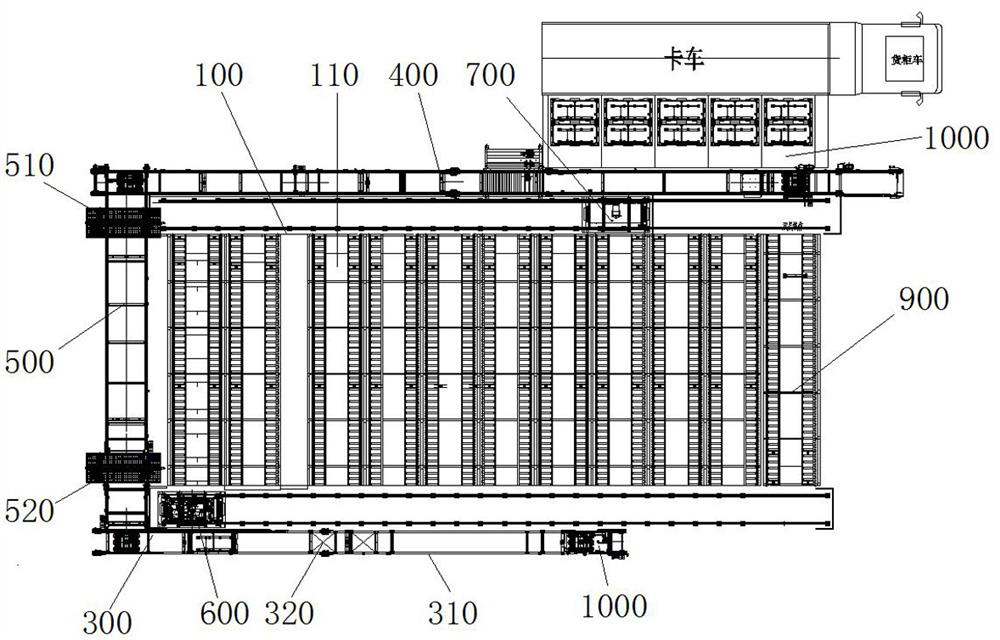

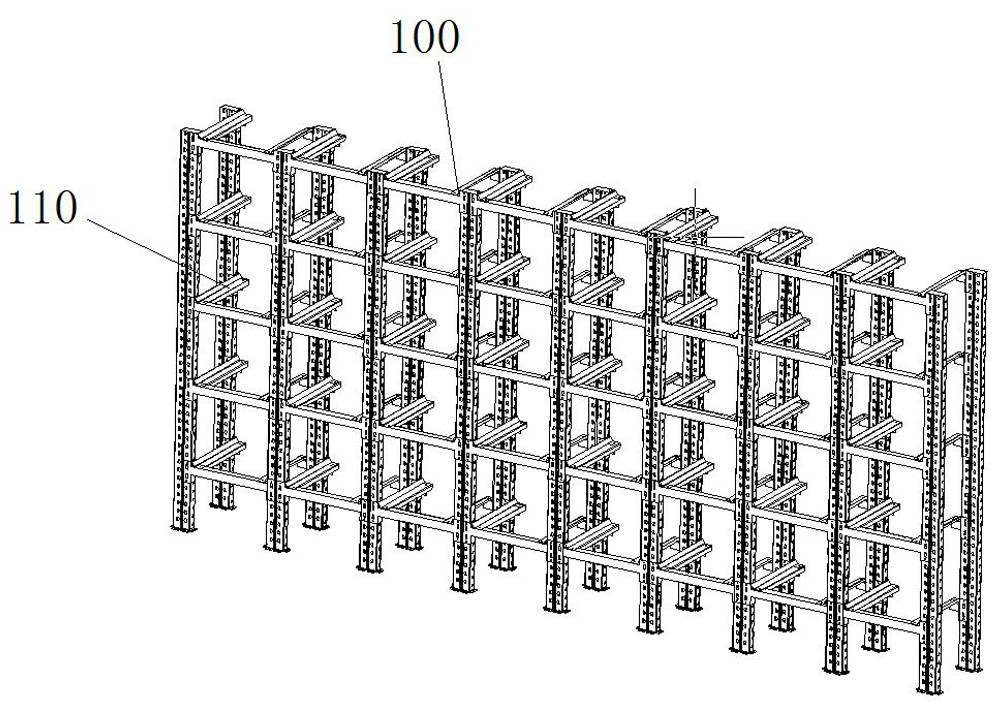

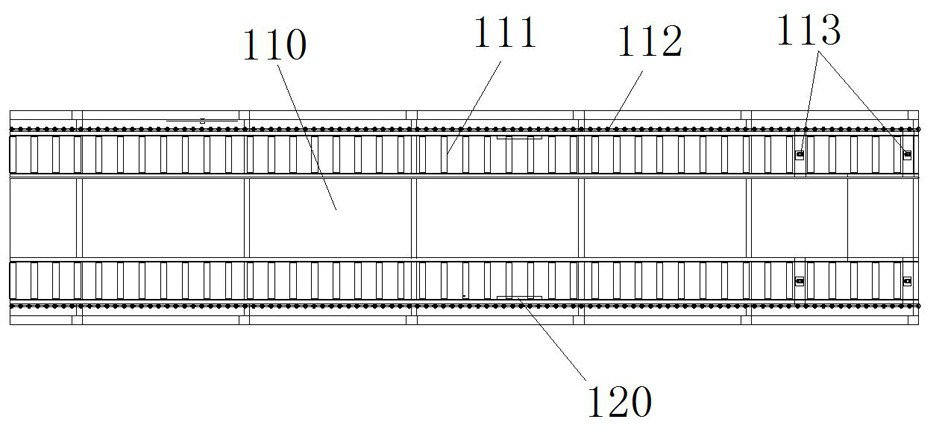

[0029] Such as Figure 1~12 As shown, a car seat storage device includes a storage shelf 100 and a tooling pallet 200 for installing the seat. A slope-type slideway 110 for storing seats; the front of the storage bin 100 is provided with a warehouse-in conveyor line 300 for conveying tooling pallets 200 equipped with seats; Pallet conveying line 400, one side of storage bin rack 100 is provided with the pallet storage conveying line 500 that connects pallet conveying line and warehouse-in conveying line; The front stacker 600 and the rear stacker 700 with tooling pallets that can move left and right; The tooling pallet of the seat moves to the corresponding slope slideway 110 of the corresponding layer, and the tooling pallet is automatically moved backward by using the slope of the slope type slideway 110; The tooling pallet with the seat at the rear end of the slope slideway 110 is placed on the pallet conveyor line 400, after the seat is manually removed, the tooling pall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com