Intelligent garbage can automatic closing packaging device

A garbage can and automatic technology, applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems that affect the sealing effect and appearance, increase the length of garbage bags, consume garbage bags, etc., so as to save consumables and improve bonding The effect of quality, increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

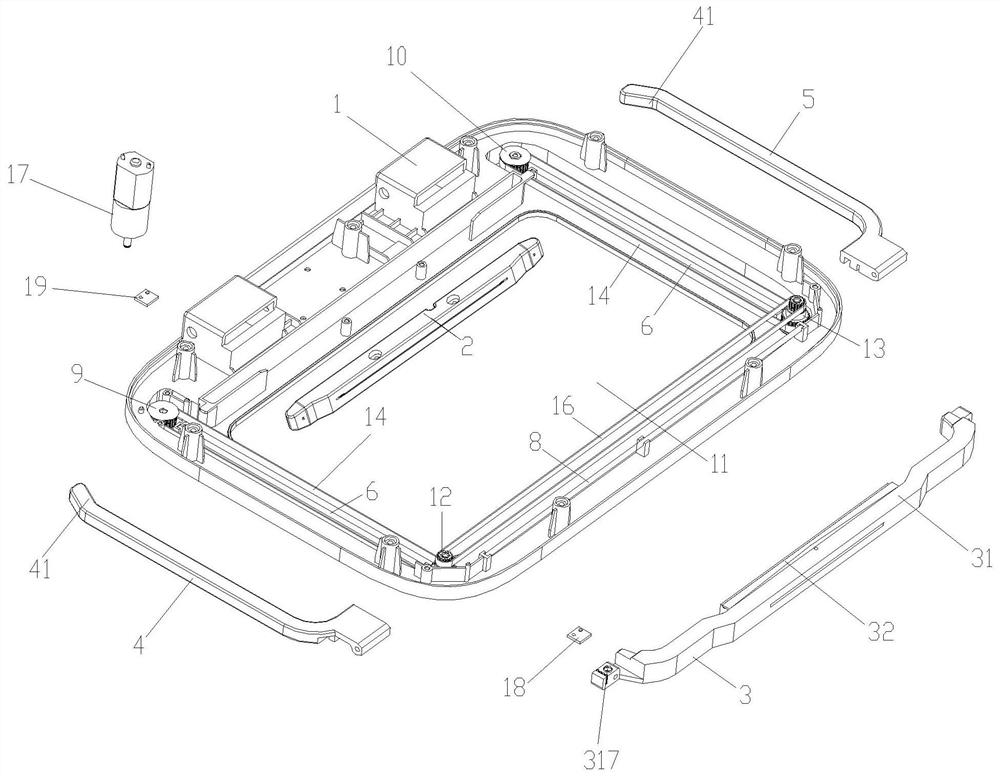

[0043] refer to figure 1 , Figure 6 , Figure 7 , Figure 8 and Figure 9, the present invention is an intelligent trash can automatic closing packaging device, including a base 1 . The base 1 is provided with a garbage drop port 11 . One side of the garbage delivery port 11 is provided with a heating wire fixing seat 2 . A side of the base 1 far away from the heating wire fixing seat 2 is provided with a longitudinal pressing rod assembly 3 that can slide and translate to the heating wire fixing seat 2 side to cooperate with the heating wire fixing seat 2 . Both sides of the heating wire fixing seat 2 are provided with a first transverse pressing bar 4 and a second transverse pressing bar 5 that can move closer to the center of the garbage delivery port 11 or separate and slide to both sides. The first horizontal pressing rod 4, the second horizontal pressing rod 5, two pressing rods, and a longitudinal pressing rod assembly 3 are arranged to cooperate with the heating...

Embodiment 2

[0050] refer to Figure 5 , on the basis of the first embodiment, the longitudinal compression rod assembly 3 includes a long fixed rod 31 and a movable compression rod 32 . The movable pressing rod 32 is rotatably connected to the long fixed rod 31 . Movable pressure rod 32 is rotatably connected with long fixed rod 31, makes movable pressure rod 32 angles not fixed, when contacting with heating wire holder 2, can automatically carry out rotation adjustment according to heating wire holder 2 angles, and the sealing heat of garbage bag The melting device fits better. It should be noted that there are many ways to rotate the connection between the long fixed rod 31 and the movable pressure rod 32, which can be connected by pin shafts, or protruding structures can be arranged on both sides of the long fixed rod 31, and the protruding structures A curved surface is set inside, and the two ends of the movable pressure rod 32 are respectively slidingly connected with the curved s...

Embodiment 3

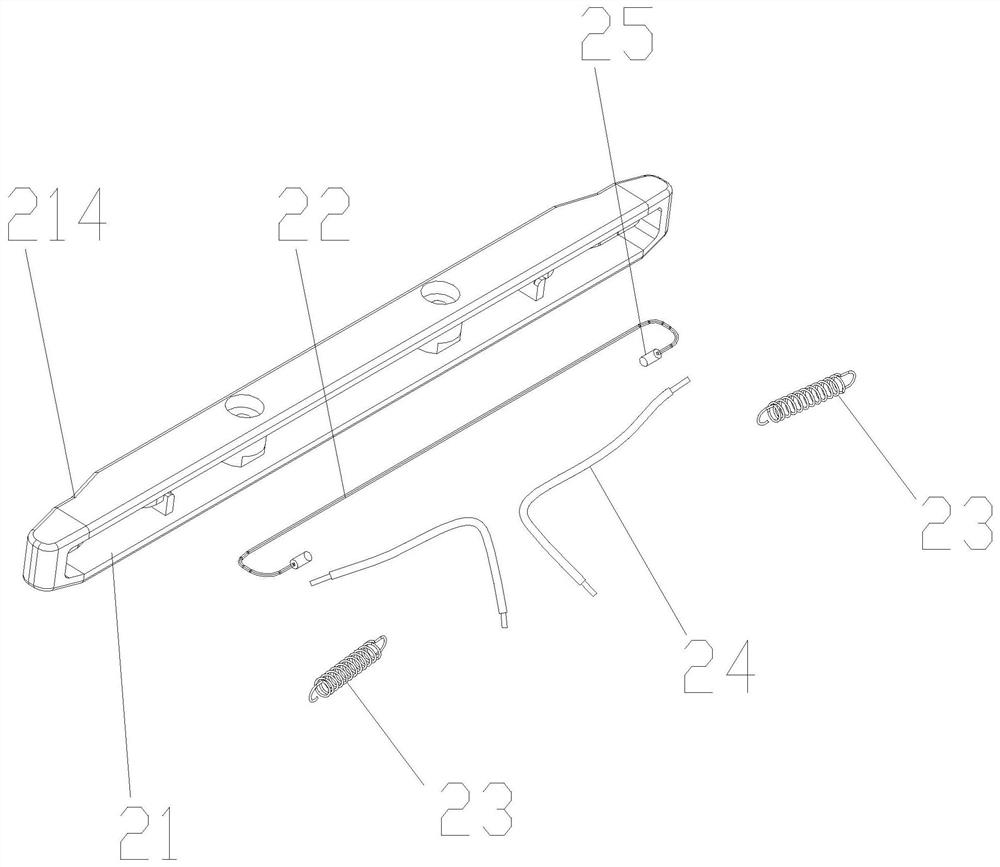

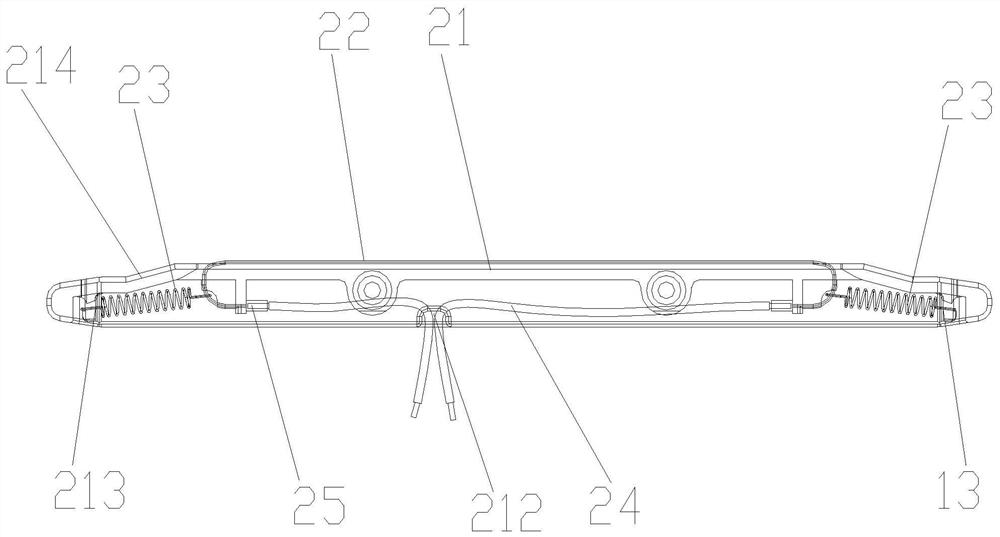

[0059] refer to Figure 2-4 , The heating wire fixing base 2 includes a fixing base 21 and a heating wire 22 arranged on the fixing base 21 . Two sides of the fixing seat 21 are provided with tension springs 23 for stretching the heating wire 22 away from the center of the heating wire 22 and realizing tension. Tension springs 23 are set in the fixed seat 21 to pull the two ends of the heating wire 22, straighten the heating wire 22, keep the heating wire 22 in a tight state, effectively prevent the heating wire 22 from loosening, and improve the heating wire 22. Garbage bag fit quality. It should be noted that, in specific embodiments, tension springs 23 can be arranged on either side or both sides of the fixing seat 21 according to requirements, and the cost of one spring is lower.

[0060] refer to figure 2 , Both ends of the heating wire 22 are provided with terminals 25 . The end of the connection terminal 5 away from the heating wire 2 is connected with a power line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com