A low-infrared characteristic nozzle

An infrared and nozzle technology, applied in the direction of jet propulsion devices, machines/engines, etc., can solve problems such as abnormal changes in bypass ratio, achieve the effects of reducing infrared radiation characteristics, reducing visible area, and significant expansion and contraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

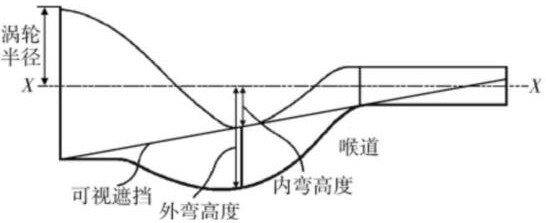

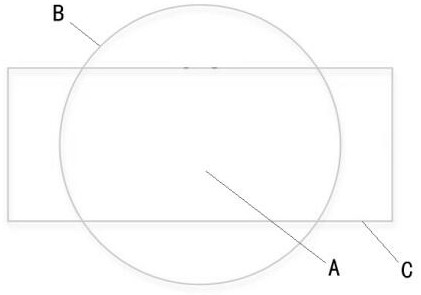

[0030] A low infrared feature nozzle of this embodiment includes connotation 1 and a connotation 2, a connotation 1 body, and an outlet located in the connotation 2, and the flow path between Handan 2 and Connotation 1 Tao, the flow path in the connotation 1 is the connotation flow path, the longitudinal surface of the main part of the connotation 1 and the main part of the Hualin 2 is circular, of which: Connotation 1 main body to the connotation 1 outlet through smooth round rectangle makes the connotation 1 exit There is a certain amount of rectangular outlet, and the outlet end of the connotation 1 is mounted with a telescopic structure 3. The connotation flow path fluid can push the telescopic structure 3, so that it extends, reducing the width of the overall flow, thereby increasing the flow The fluid pressure in the road has forces some of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com