A wear-resistant bushing assembly

A wear-resistant lining and component technology, applied in the field of linings, can solve the problem of high temperature, achieve the effects of safe and convenient use, avoid poor wear resistance, and increase the number of wear-resistant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

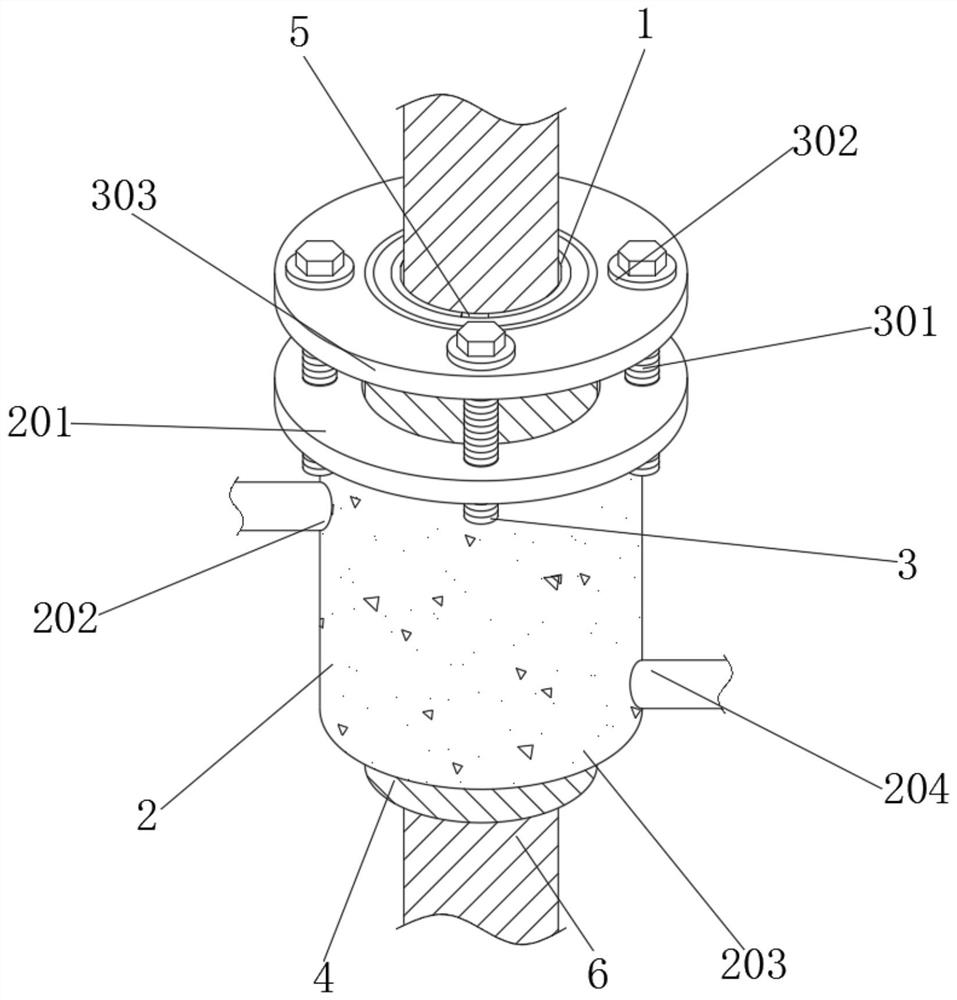

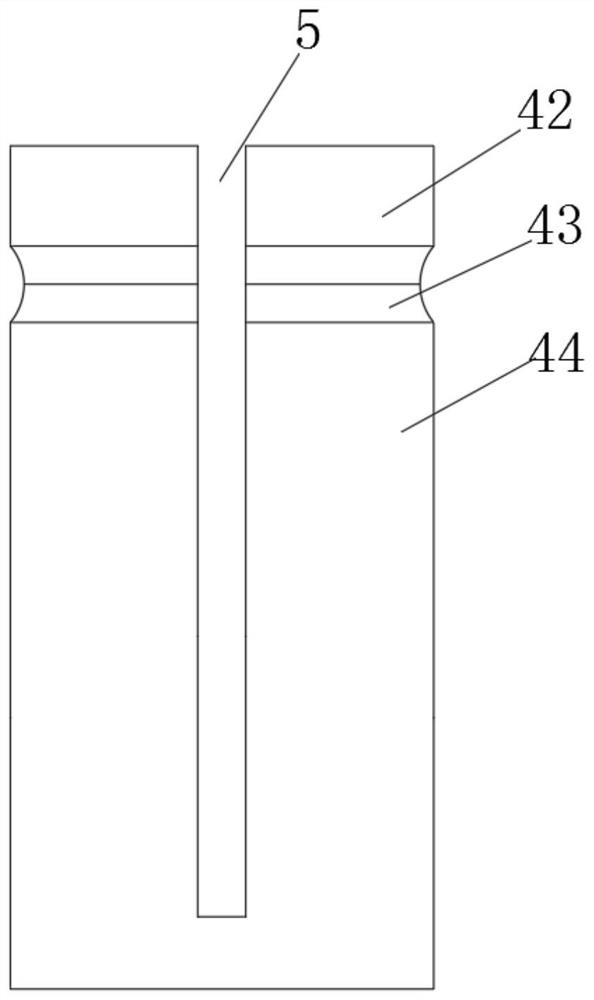

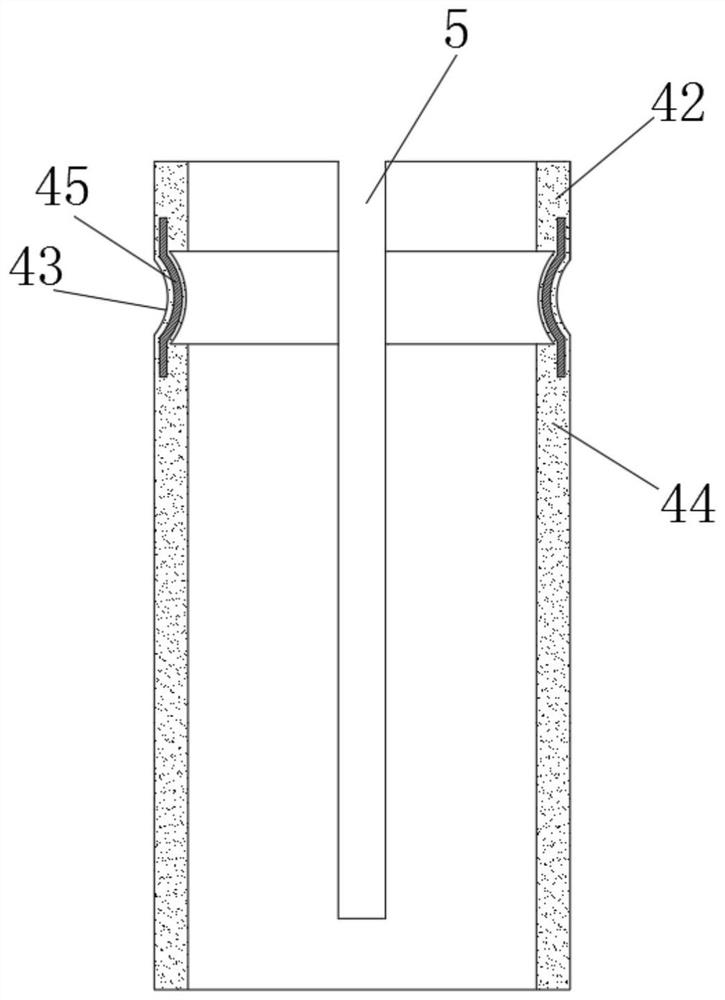

[0037] A wear-resistant and anti-corrosion rubber bushing assembly, comprising a bushing 1 and a shaft member 6, the inner central position of the bushing 1 is provided with a shaft member 6, the inner and outer sides of the bushing 1 are installed with a protection component 4, and the protection component 4 includes anti-corrosion Layer 401 and wear-resistant layer 402, the anti-corrosion layer 401 is arranged under the outer wall of the bushing 1, and the wear-resistant layer 402 is arranged on the inner wall of the bushing 1 to limit the relative position of the anti-corrosion layer 401 and the wear-resistant layer 402 and the bushing 1, the anti-corrosion layer 401 and the wear-resistant layer 402 are at the same height as the cut surface of the lower end of the bushing 1, the shaft member 6 and the wear-resistant layer 402 are attached to each other, and both the left and right ends of the wear-resistant layer 402 are machined with oil grooves 5, and the oil grooves 5 can ...

Embodiment 2

[0042] As an optional case, see Figure 1-8 , a wear-resistant and anti-corrosion rubber bushing assembly, a mounting assembly 3 is arranged above the outer wall of the bushing 1, and the mounting assembly 301 includes a screw 301, a backing plate 302 and a second horizontal plate 303, and the plurality of screws 301 and the backing plate 302 are located in the second The upper end, left and right sides of the horizontal plate 303 are at the front and rear ends. The screw 301 and the backing plate 302 are in clearance fit. Closely fit, the fixed connection between the first horizontal plate 201 and the second horizontal plate 303 and the bushing seat can be realized by the screws 301, the inner wall of the second horizontal plate 303 is fixedly connected with the upper end of the outer wall of the bushing 1, and the second horizontal plate 303 is fixedly connected The height of the upper end surface of the horizontal plate 303 is the same as the height of the upper end surface...

Embodiment 3

[0045] As an optional case, see figure 1 , 4 And 7, wear-resistant and anti-corrosion rubber bushing assembly, a cooling assembly 2 is installed under the outer wall of the bushing 1, and the cooling assembly 2 includes a first horizontal plate 201, a drain pipe 202, a sleeve 203, a water inlet pipe 204 and a water tank 205. The first The horizontal plate 201 is located below the second horizontal plate 303 , and a sleeve 203 is fixed inside the lower end of the first horizontal plate 201 . The sleeve 203 can drive the first horizontal plate 201 to move on the outer wall of the bushing 1 . The sleeve 203 and The inner wall of the first horizontal plate 201 is in clearance fit with the anti-corrosion layer 401, and the sleeve 203 and the first horizontal plate 201 are fixedly connected with the screws 303. The inside of the sleeve 203 is machined with a water groove 205, and the water inlet pipe 204 is installed and connected to the sleeve. Inside the lower right end of 203, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap