Anti-backlash type steering transmission shaft steel ball retainer

A technology for steering transmission shafts and cages, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., and can solve problems such as abnormal noise and lack of anti-backlash function, so as to prevent abnormal noise, reduce spline wear, and eliminate gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

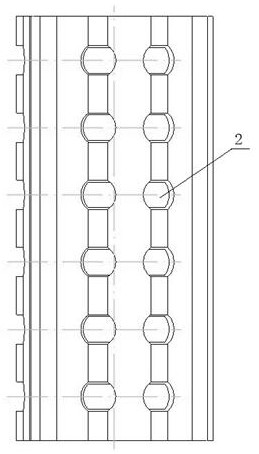

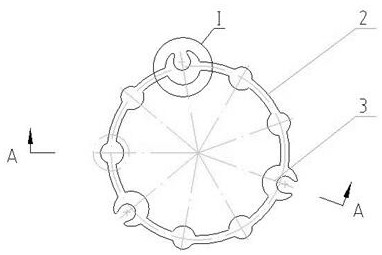

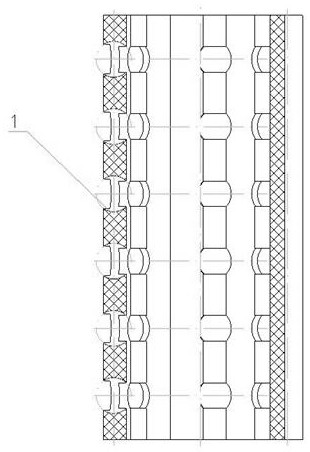

[0016] Referring to the accompanying drawings, a backlash-removing steel ball cage for a steering transmission shaft includes a ball bowl 1, a steel ball cage 2, a C-shaped opening 3, an eccentric cylinder 4, a cylinder 5, a transmission sleeve 6, and a transmission shaft 7. The steel ball cage 2 is provided with 6 rows of parallel ball bowls 1 for fixing the steel balls, which has a large bearing torque, and three rows of C-shaped openings 3 are arranged at 120° around the steel ball cage 2; the C-shaped openings 3 have a raised shape It is arc-shaped, and the middle of the C-shaped opening 3 is a hollow structure; the C-shaped opening 3 is composed of two eccentric cylinders 4 and 5, forming an elastically deformable arc surface, and the connection between the cylinder 5 and the transmission shaft 7 and the transmission sleeve 6 Fairway interference fit, the circular arc surface and the drive shaft sleeve tightly fit to eliminate radial clearance during work;

[0017] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com