Engineering quality detector for building supervision

A technology of engineering quality and detectors, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that inspectors need to carry a large number of inspection equipment, cannot achieve multiple detection synchronization, and cannot synchronize sampling, etc., so as to facilitate detection , Safe and convenient to use, and the effect of reducing detection errors

Active Publication Date: 2020-12-11

浙江嘉宇工程管理有限公司

View PDF13 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention provides an engineering quality detector for construction supervision, which can effectively solve the problem that the quality detector cannot be changed according to the size of the detected position when performing detection in the above-mentioned background technology, and cannot effectively detect a small space. At the same time, it is impossible to sample simultaneously during detection, so that the detection personnel need to carry a large number of detection equipment, and the detection process is cumbersome, and it is impossible to perform multiple detections simultaneously.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

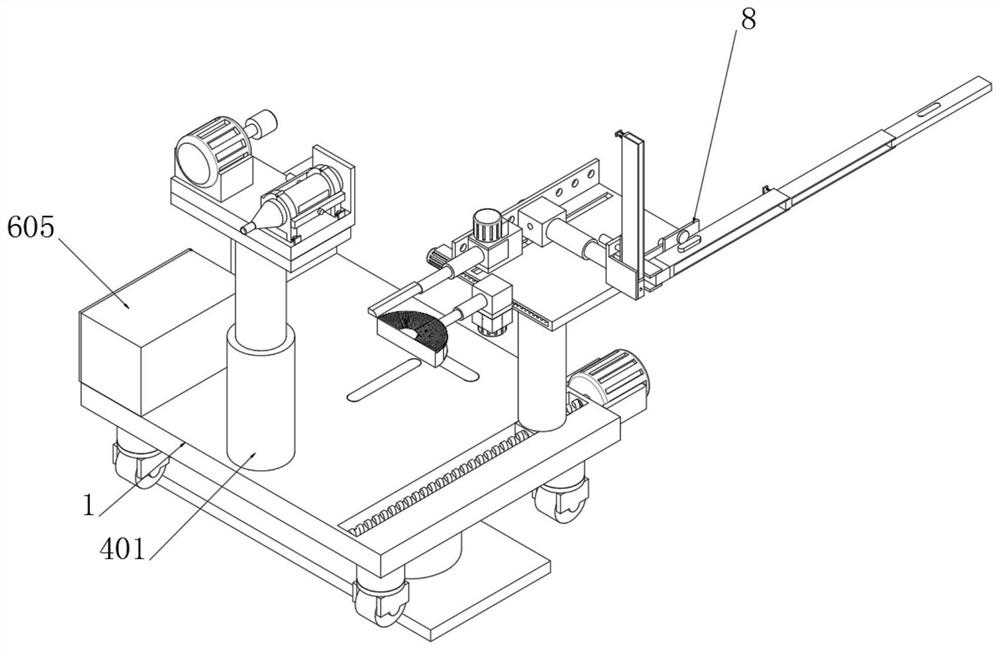

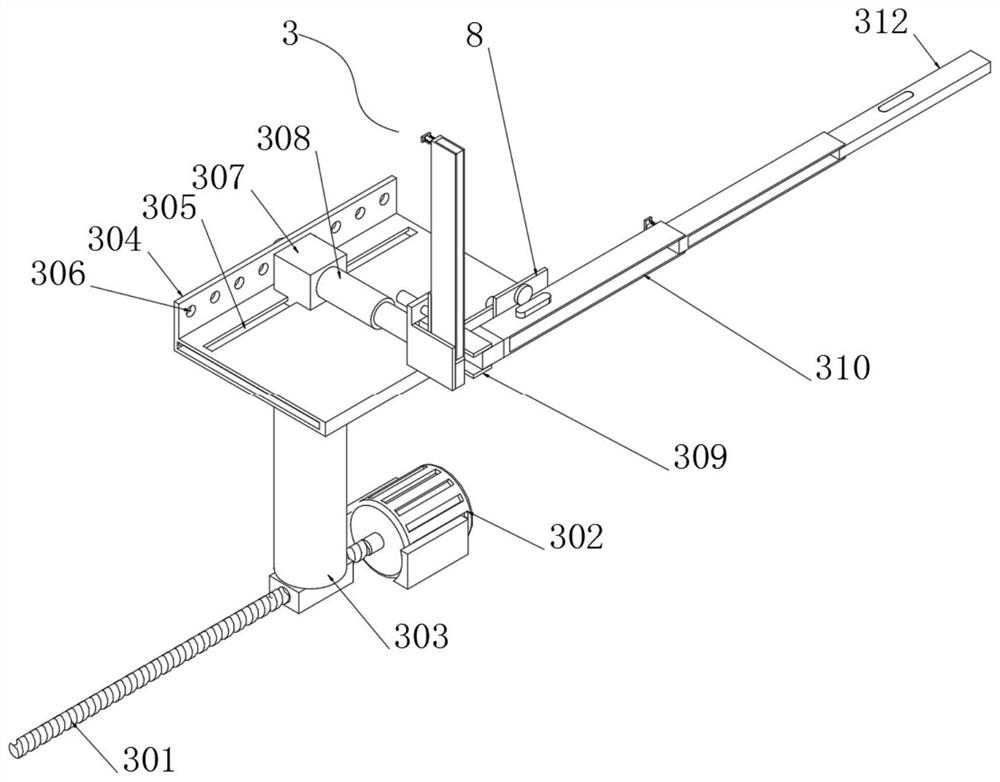

[0056] Example: such as Figure 1-10 As shown, the present invention provides a technical solution; an engineering quality detector for construction supervision, a limit moving groove 2 is provided on the top side of the load-bearing support plate 1, and a leveling component 3 is slidably connected to the inner side of the limit moving groove 2, and the leveling component 3 Fine-tune the flatness to reduce the error in detection;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

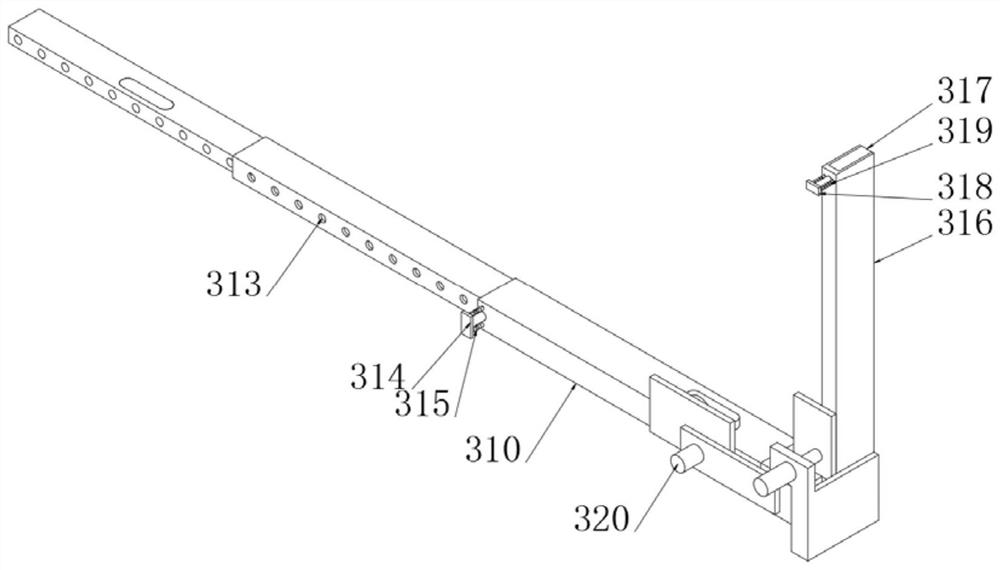

The invention discloses an engineering quality detector for building supervision. A moving screw rod is rotatably connected to the inner side of a limiting moving groove, a bearing hydraulic cylinderis connected to the moving screw rod through a screw rod seat, an L-shaped mounting plate is fixedly connected to the top end of the bearing hydraulic cylinder, a moving fixing block is connected to the top end of the L-shaped mounting plate, and an extending electric push rod is connected to the output end of the moving fixing block; one end of the extending electric push rod is connected with alimiting clamping plate, one end of the limiting clamping plate is connected with a flatness detection plate, and the position, away from the flatness detection plate, of one end of the limiting clamping plate is rotationally connected with a vertical detection plate. Through adjusting the length of the detection plate, a detector can detect the spaces with difference sizes conveniently, the problem that spaces of different sizes cannot be detected due to the fact that the length of the detection plate is fixed is avoided, a plurality of detection plates do not need to be carried, meanwhile, the detection plates are pushed through the electric push rod to be attached to the wall surface, detection errors caused by untight attachment are reduced, and therefore the accuracy of detection datais guaranteed.

Description

technical field [0001] The invention relates to the technical field of construction supervision, in particular to an engineering quality detector for construction supervision. Background technique [0002] Construction supervision refers to the completion of the construction project, the inspection and acceptance of the project, and the inspection to check whether the project meets the requirements of the state for engineering construction, so as to facilitate the management and control of the project. Now when the project is inspected and accepted, testing instruments are generally used to check the overall project Fixed-point detection. [0003] However, the quality detectors currently on the market cannot change according to the size of the detected position when performing detection, and cannot effectively detect small spaces. At the same time, they cannot simultaneously sample during detection, so that inspectors need to carry a large number of detection Equipment, and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B21/30G01B21/22G01C9/00G01N3/52G01N1/08

CPCG01B21/30G01B21/22G01C9/00G01N3/52G01N1/08G01N2203/0083

Inventor 金秀云

Owner 浙江嘉宇工程管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com