Breaker non-full-phase function testing device

A function test and circuit breaker technology, which is applied in the direction of circuit breaker test, measuring device, instrument, etc., can solve the problems of high number of actions, short circuit of control circuit, difficult cooperation, etc., and achieve improved safety performance, improved work efficiency, inspection work intuitively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

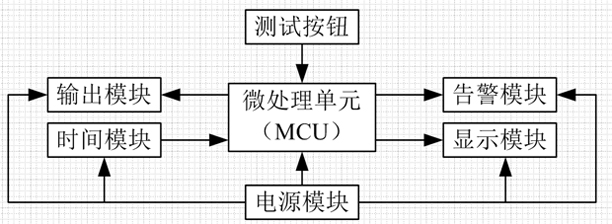

[0036] This embodiment provides a non-full-phase functional testing device for a circuit breaker, which includes a power supply module, an alarm module, an output module, a micro-processing unit MCU, a display module, a test button and a time module.

[0037] Further, the power supply module is electrically connected to the alarm module, output module, MCU, display module, test button and time module respectively.

[0038] The power supply module provides electric energy for the alarm module, the output module, the micro-processing unit MCU, the display module, the test button and the time module respectively.

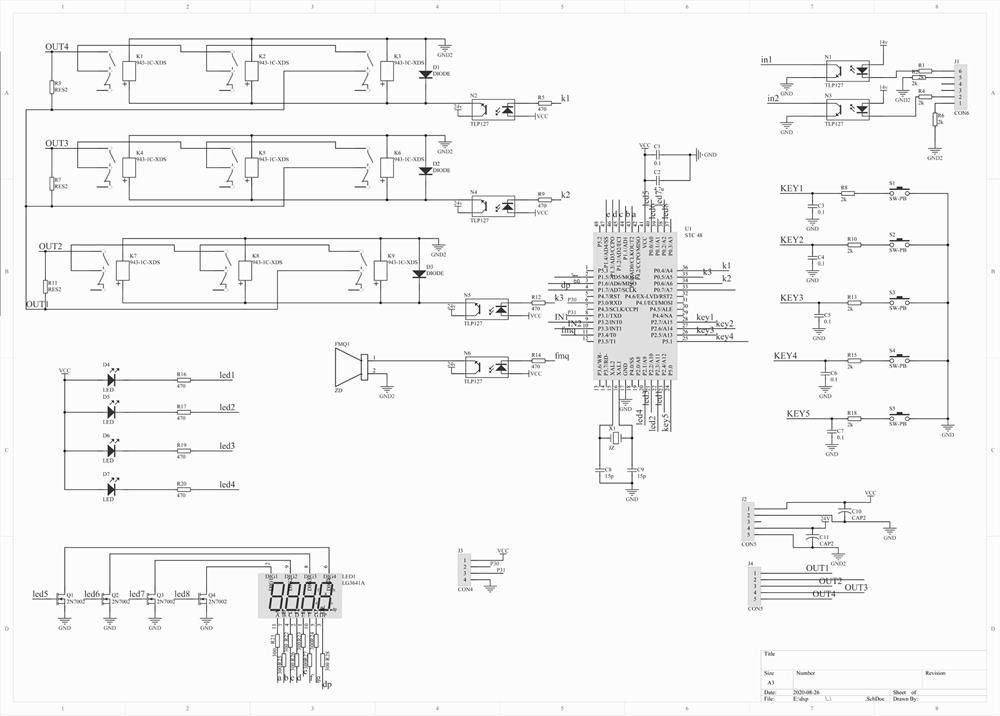

[0039] Further, the power supply module converts the AC 220V into two power supply isolation outputs, one of which is rectified and filtered by BG400, and then converted into a 5V regulated output VCC1 by DC-DC, which is respectively supplied to the micro-processing unit MCU, display module, test button, The time module and the alarm module are powered; the other one i...

Embodiment 2

[0043] This embodiment provides a non-full-phase functional testing device for a circuit breaker, which includes a power supply module, an alarm module, an output module, a micro-processing unit MCU, a display module, a test button and a time module.

[0044] Further, the power supply module is electrically connected to the alarm module, output module, MCU, display module, test button and time module respectively.

[0045] The power supply module provides electric energy for the alarm module, the output module, the micro-processing unit MCU, the display module, the test button and the time module respectively.

[0046] Further, the power supply module converts the AC 220V into two power supply isolation outputs, one of which is rectified and filtered by BG400, and then converted into a 5V regulated output VCC1 by DC-DC, which is respectively supplied to the micro-processing unit MCU, display module, test button, The time module and the alarm module are powered; the other one i...

Embodiment 3

[0052] This embodiment provides a non-full-phase functional testing device for a circuit breaker, which includes a power supply module, an alarm module, an output module, a micro-processing unit MCU, a display module, a test button and a time module.

[0053] Further, the power supply module is electrically connected to the alarm module, output module, MCU, display module, test button and time module respectively.

[0054] The power supply module provides electric energy for the alarm module, the output module, the micro-processing unit MCU, the display module, the test button and the time module respectively.

[0055] Further, the power supply module converts the AC 220V into two power supply isolation outputs, one of which is rectified and filtered by BG400, and then converted into a 5V regulated output VCC1 by DC-DC, which is respectively supplied to the micro-processing unit MCU, display module, test button, The time module and the alarm module are powered; the other one i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com