Electricity-heat-gas multi-stress combined aging experiment platform and experiment method for insulating material

A technology of insulating materials and aging experiments, applied in the field of high-voltage insulation, to achieve the effect of convenient experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

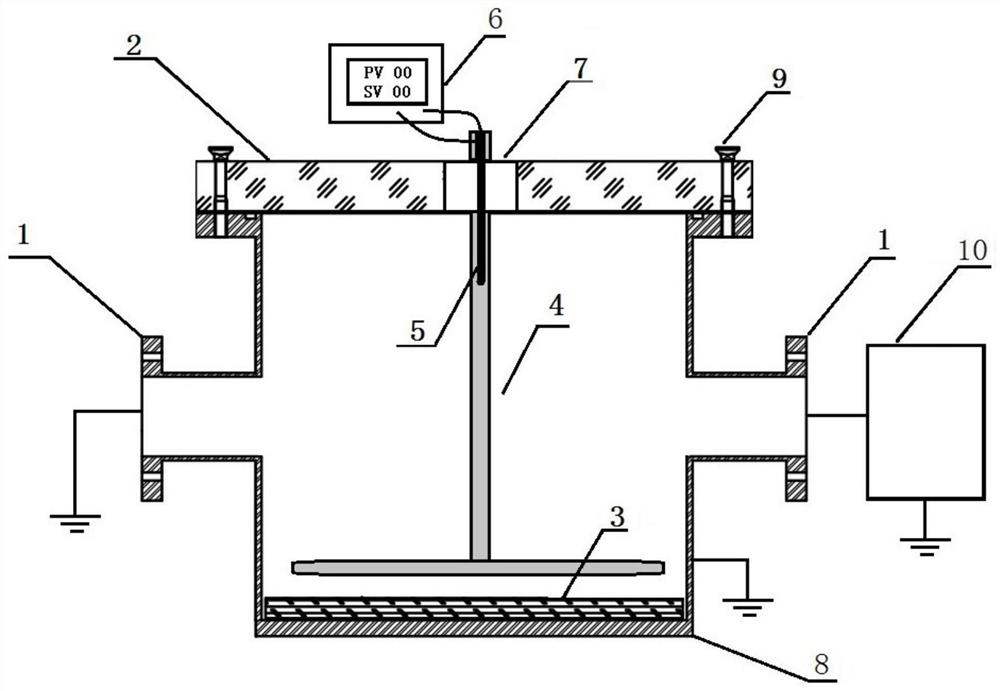

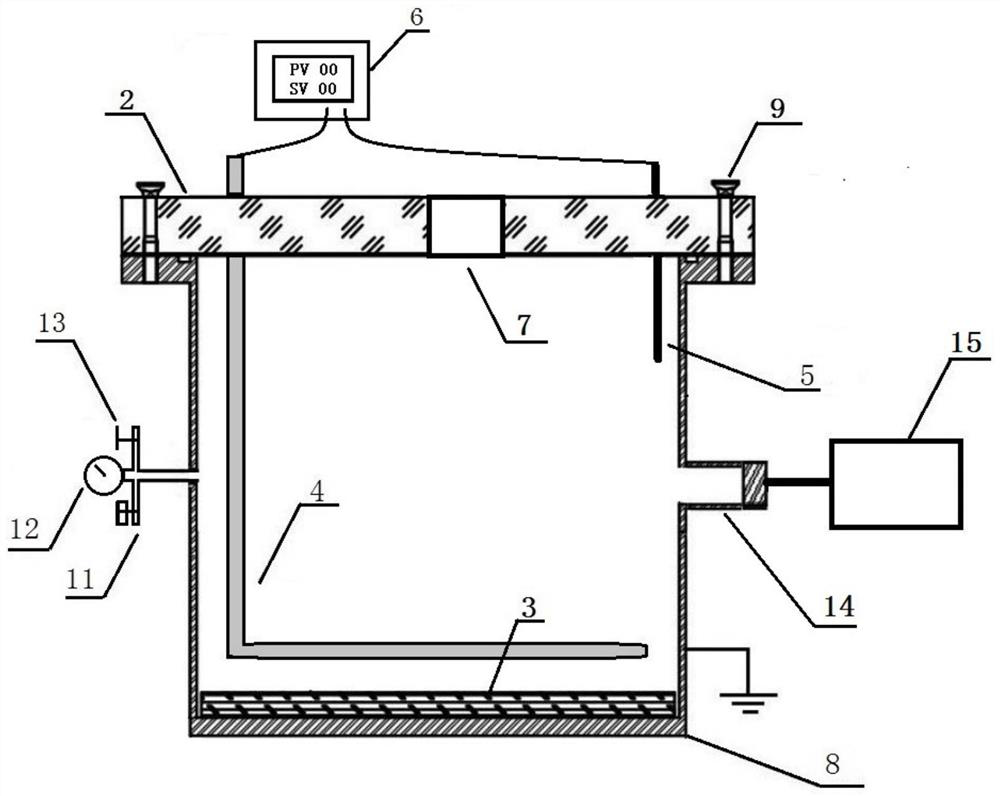

[0070] The surface flashover performance test of epoxy micro-composite insulating materials after electric-thermal-gas multi-stress combined aging is as follows:

[0071] 1) Take the epoxy micro-composite insulating material and pretreat it. The specific operation of pretreatment is: use absolute ethanol and deionized water, clean it with an ultrasonic cleaner for 30 minutes, remove dust and stains on the surface, and place it in a vacuum oven at 60°C , drying for 12 hours, so that the drying degree of the epoxy micro-composite insulating material meets the specified experimental requirements;

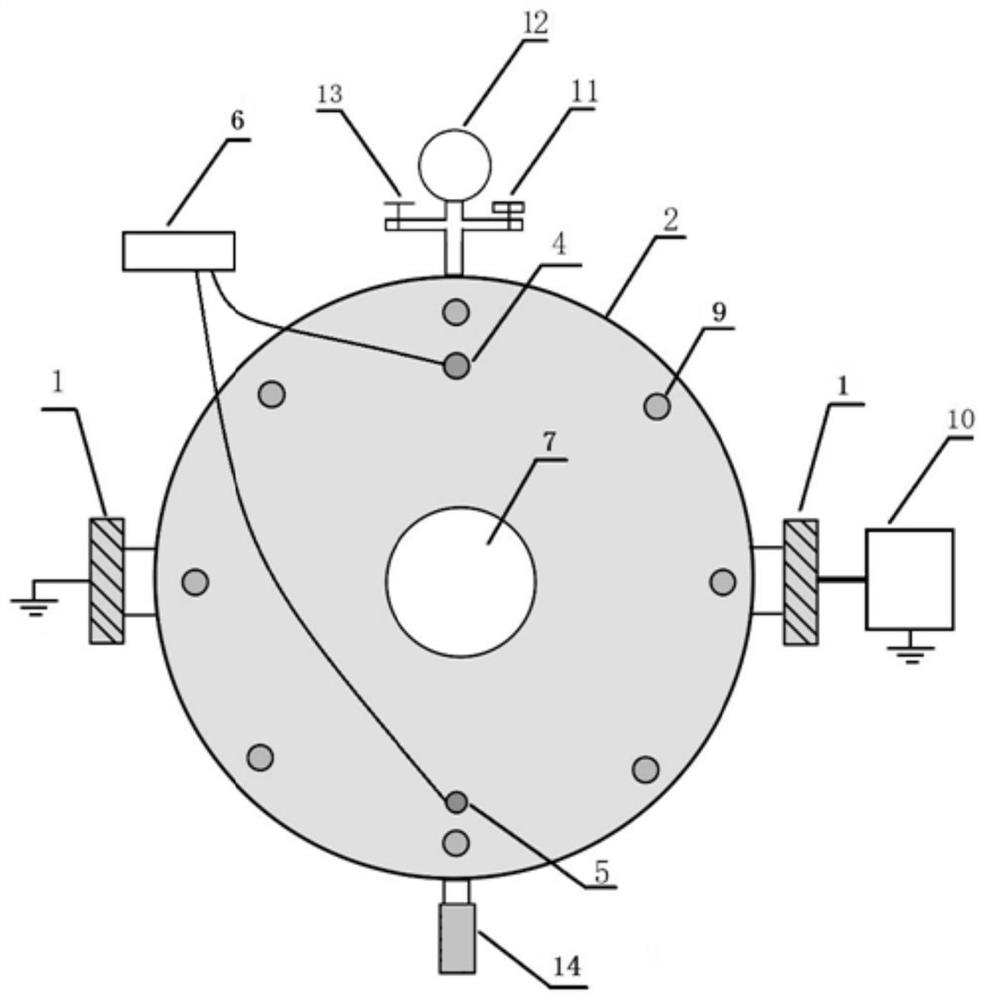

[0072] 2) Put the epoxy micro-composite insulating material in the finger electrodes, the electrode spacing is 5mm, connect the two tail ends of the finger electrodes with the high voltage electrode 1 on the cavity wall with high voltage resistant wires.

[0073] 3) After the experimental cavity 8 is evacuated by the vacuum pump 15, the gas injection port 11 and the SF 6 The gas cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com