Bottom combined anti-collision structure for high-temperature gas cooled reactor control rod

A high-temperature gas-cooled reactor and control rod technology, which is applied in the reduction of greenhouse gases, control of nuclear reactions, and reactors, etc., can solve the problems of reactivity control performance impact, buffer performance impact, reverse jumping, etc., to protect the structural integrity. , Guarantee the effectiveness and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

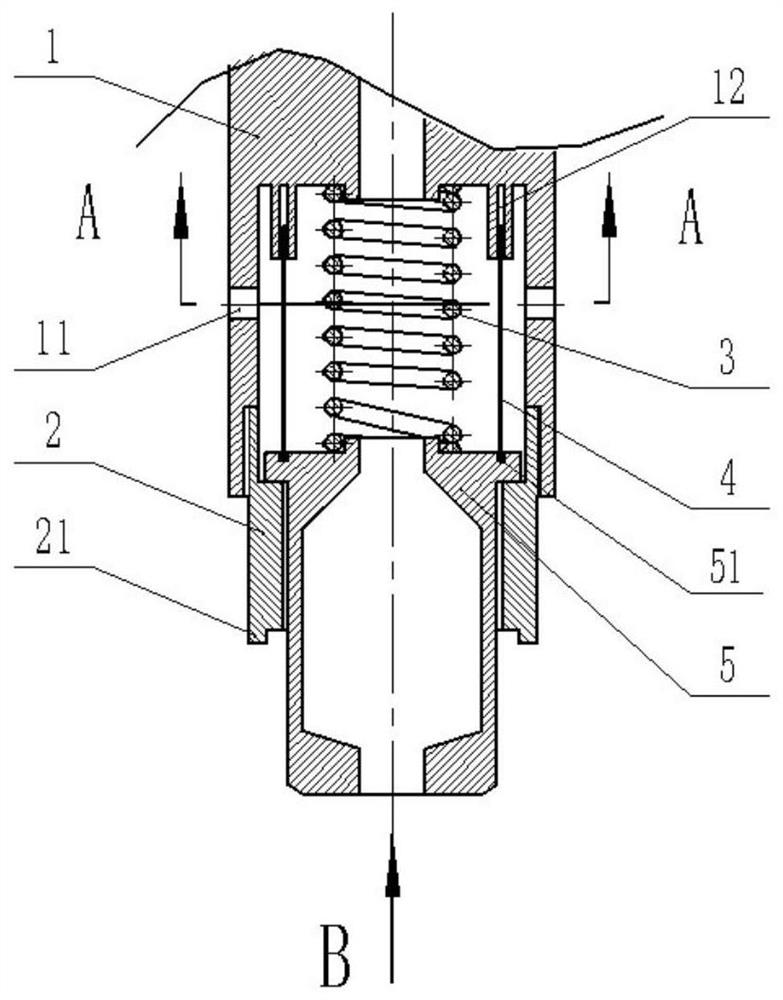

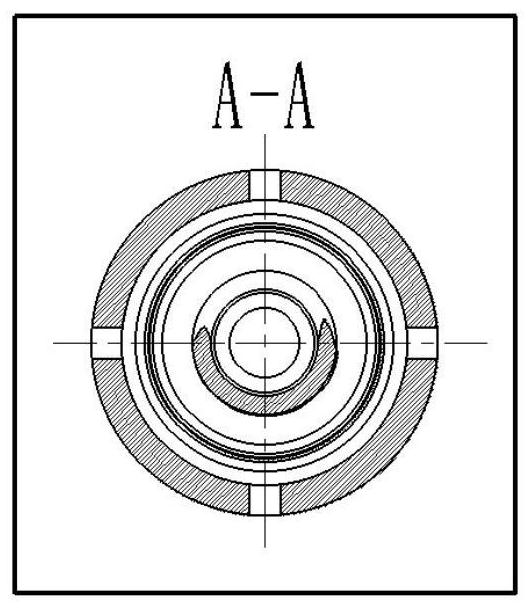

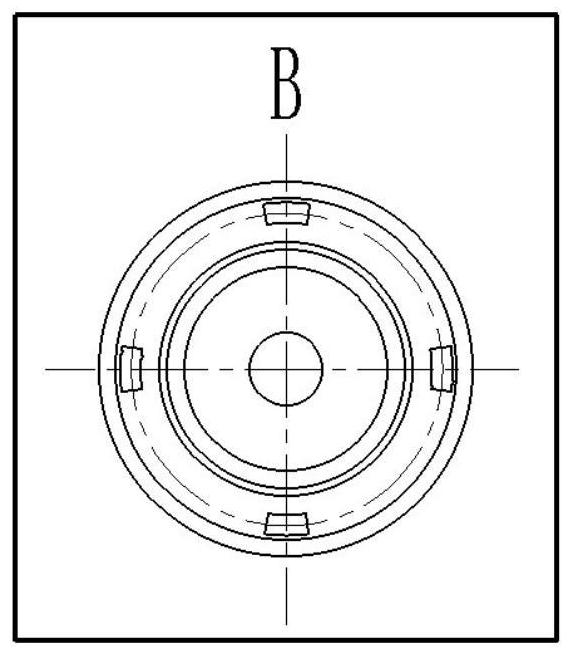

[0035] like Figure 1-3 As shown, the bottom combined anti-collision structure for the control rods of the high temperature gas-cooled reactor in this embodiment is composed of the rod body 1, the tightening ring 2, the spring 3, the thin-wall crushing cylinder 4 and the buffer joint 5. A communication hole 11 is provided on the outer wall of the rod body 1 to connect the outer chamber of the thin-walled crushing cylinder 4 with the external environment. In addition, a guide groove 12 is provided on the rod body, and a groove 51 is provided at the upper end of the buffer joint 5, which is used to limit the displacement of the thin-walled crushing cylinder 4 to avoid off-axis buckling during the compression process, so as to be compatible with the rod body. 1 contact or even stuck. The spring 3 is limited by the bosses on the rod body 1 and the buffer joint 4 respectively, so as to avoid its mutual contact with the rod body 1 and the thin-walled crushing cylinder 4 during the ...

Embodiment 2

[0044] Such as Figure 4-6 As shown, the bottom combined anti-collision structure for high temperature gas-cooled reactor control rods is composed of rod body 1, tightening ring 2, spring 3, thin-walled crushing tube 4, buffer joint 5 and inner cladding 6. A communication hole 11 is provided on the outer wall of the rod body 1 to connect the outer chamber of the thin-walled crushing cylinder 4 with the external environment. In addition, a guide groove 12 is provided on the rod body, and a groove 51 is provided at the upper end of the buffer joint 5, which is used to limit the displacement of the thin-walled crushing cylinder 4 to avoid off-axis buckling during the compression process, so as to be compatible with the rod body. 1 contact or even stuck. The spring 3 is limited by the inner casing 6 to prevent it from contacting the rod body 1 and the thin-wall crushing cylinder 4 during the working process. The inner cladding 6 extends downward along the center of the rod body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com