Spinning fibrous high-molecular polymer filtering device

A high-molecular polymer and filtration device technology, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of reduced production efficiency, reduced raw liquid filtration volume, reduced filtration effect, etc., and achieves the goal of improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

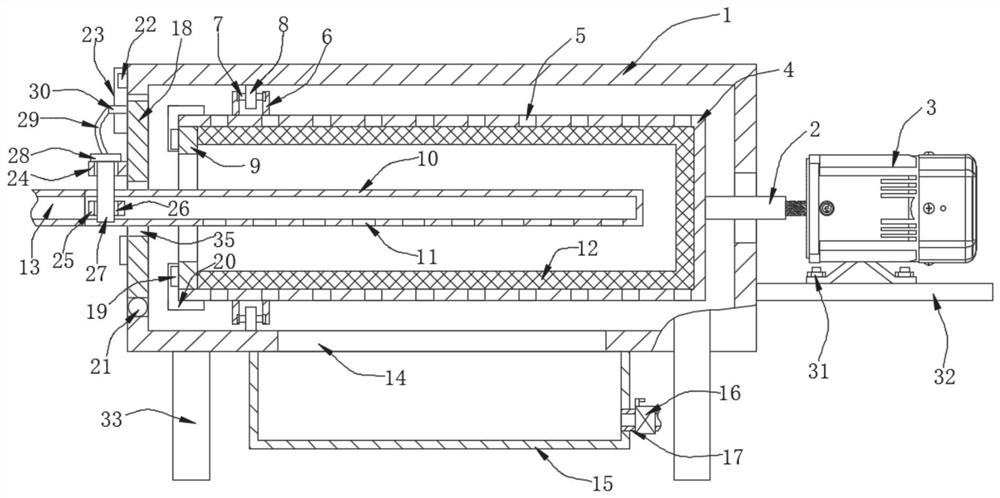

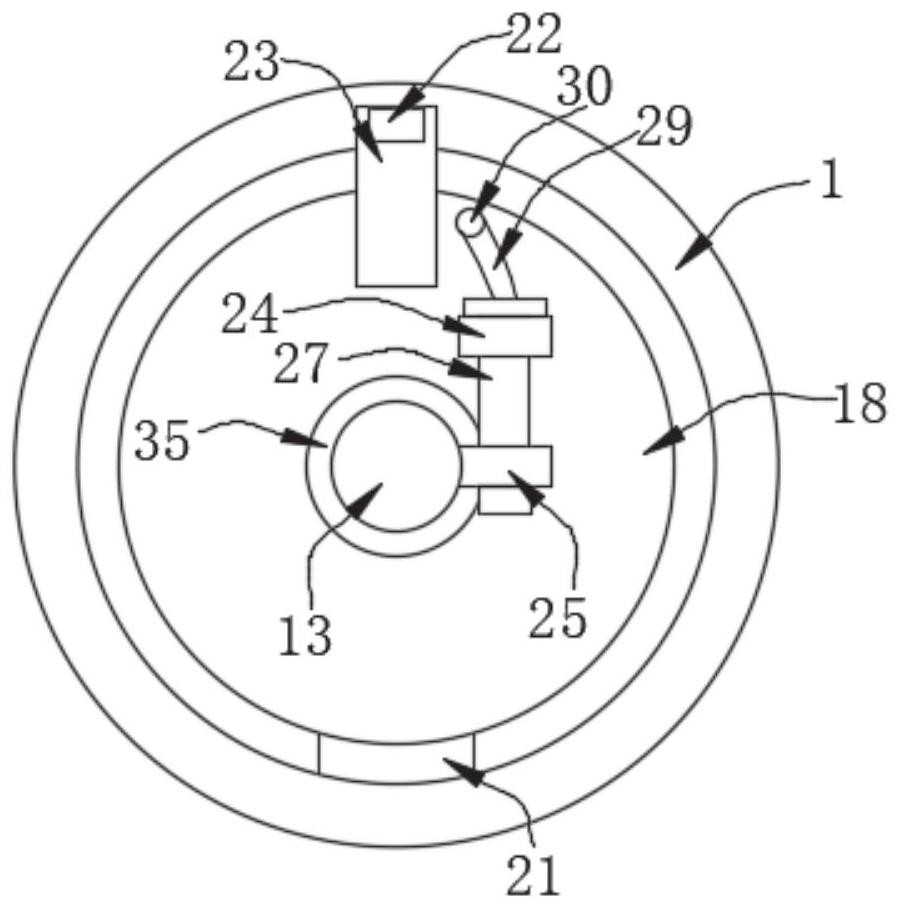

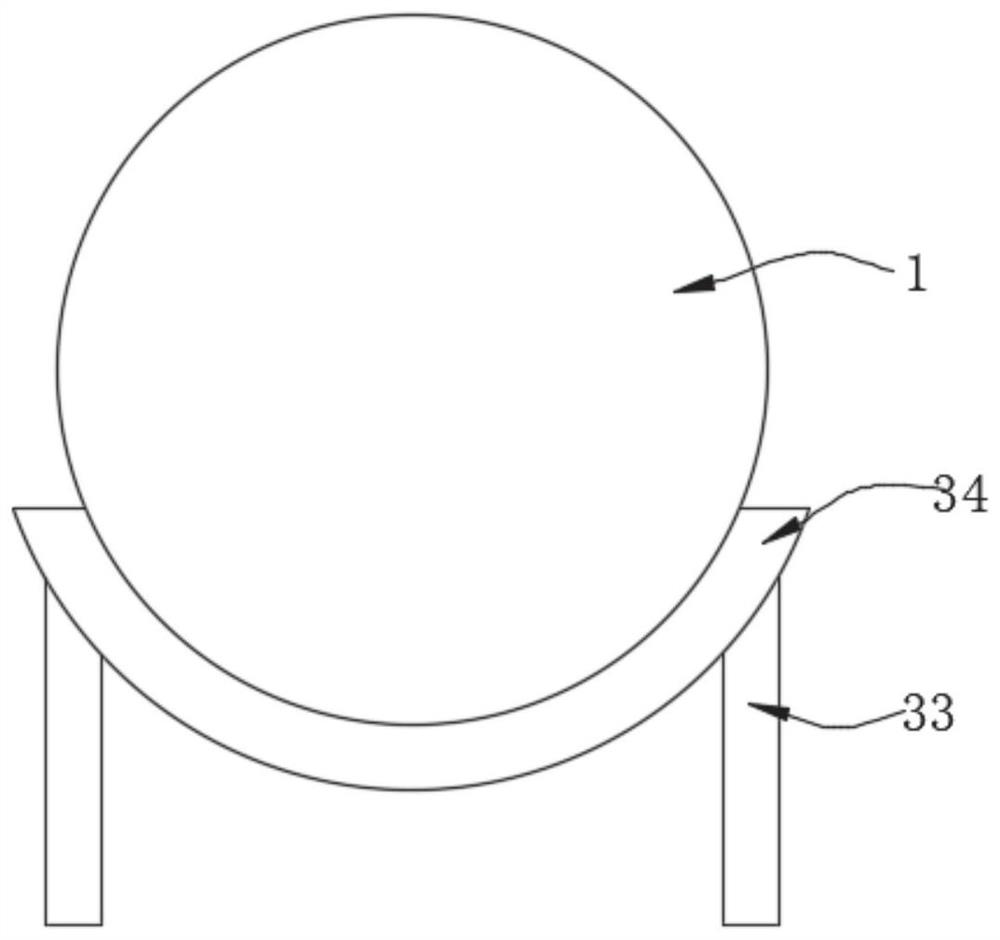

[0027] see Figure 1-4 , the present invention provides a technical solution: a high molecular polymer filter device made of spun fibers, comprising a housing 1, one side of the housing 1 is rotatably connected with a first rod 2 through a first bearing, and the first rod 2 One end of the motor 3 is fixedly connected with the motor 3 and is located outside the housing 1. A cylinder 4 is provided inside the housing 1. One side of the cylinder 4 is welded to one end of the first rod 2. The outer wall of the cylinder 4 is evenly opened with The first through hole 5, four connecting plates 6 are symmetrically welded on the outer side wall of the cylinder body 4, and the adjacent side of the two connecting plates 6 is connected with the second rod body 7 through the second bearing rotation, and the outer side wall of the second rod body 7 The wheel body 8 is welded, the inner wall of the cylinder body 4 is attached with a filter screen 12, the inner side wall of the cylinder body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com