Hidden fire hydrant

A fire hydrant and concealed technology, which is applied in the field of concealed fire hydrants, can solve the problems of safety risks, pedestrian obstruction, and easy collision, etc., and achieve the effect of simple and convenient operation and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

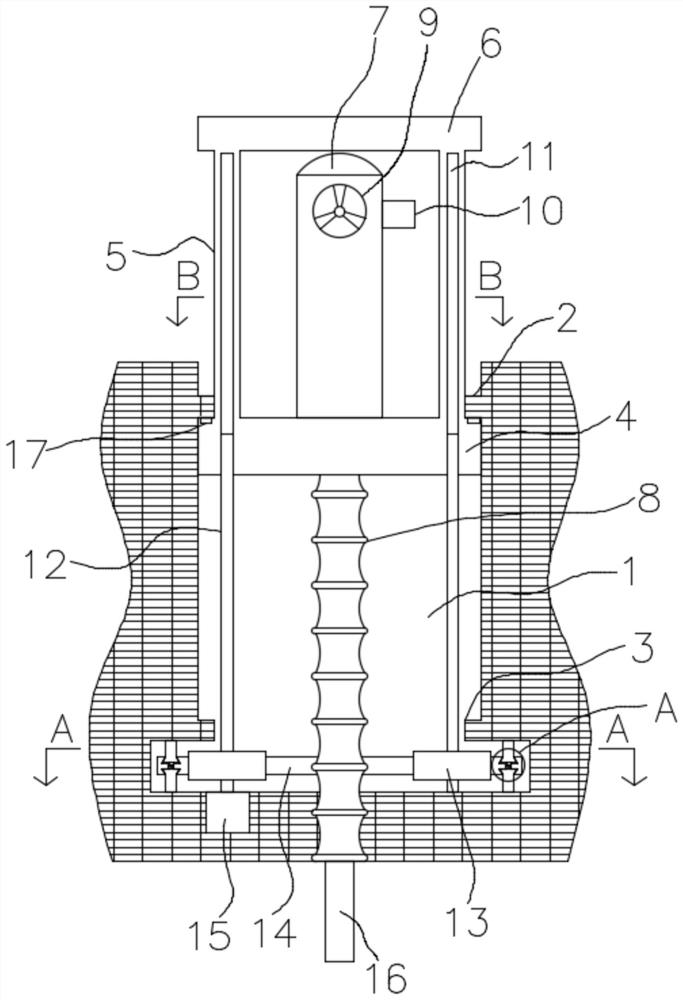

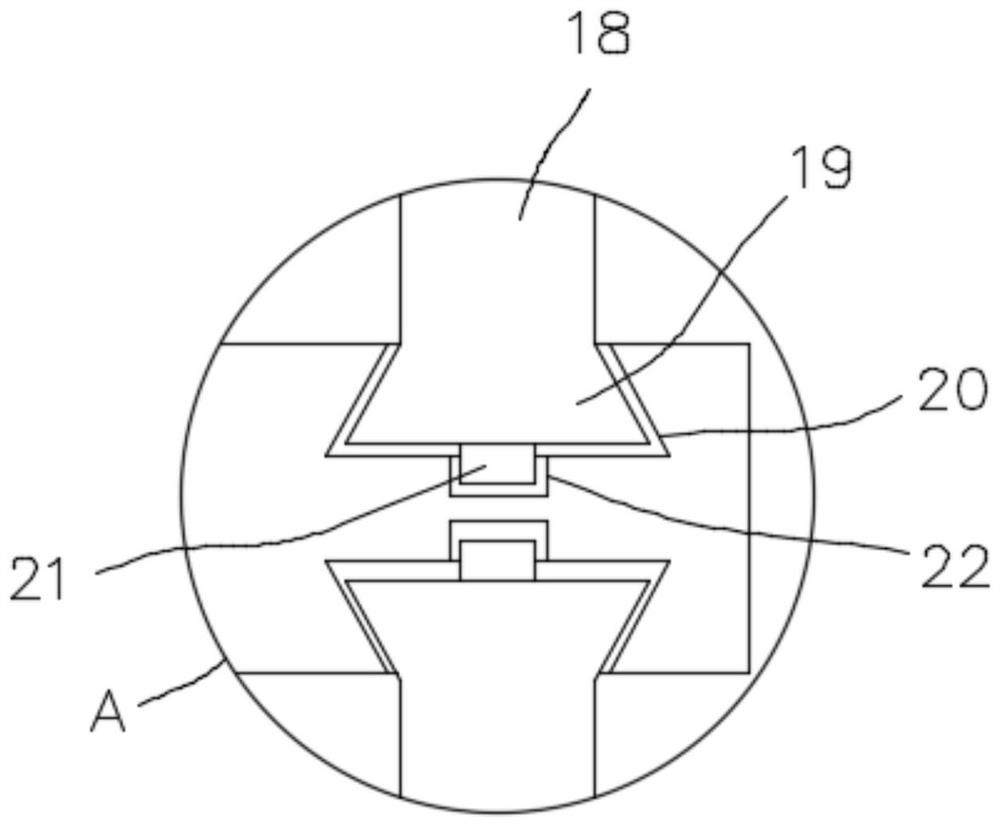

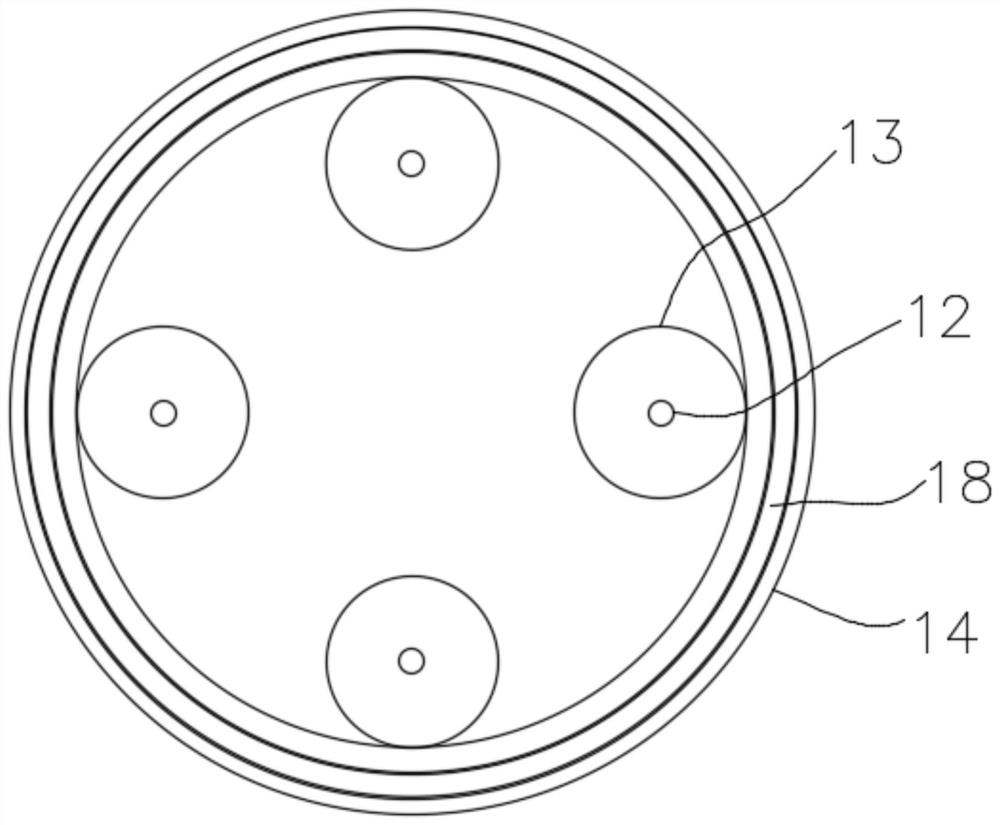

[0027] refer to Figure 1-5 , a concealed fire hydrant, comprising a cylindrical groove 1 on the ground, an annular groove is formed at the inner bottom of the groove 1, and a first The annular protrusion 2 and the second annular protrusion 3 are slidingly connected with a bottom plate 4 in the groove 1 and between the first annular protrusion 2 and the second annular protrusion 3. The upper end of the bottom plate 4 is uniformly integrated with its own axis as the center of the circle. A plurality of connecting columns 5 are formed, the upper ends of the plurality of connecting columns 5 are integrally formed with a top plate 6, and the middle part of the upper end of the bottom plate 4 is fixedly equipped with a fire hydrant body 7, which is the prior art, and the water inlet end of the fire hydrant body 7 is connected with a telescopic The pipe 8 and the upper end of the telescopic pipe 8 are set through the bottom plate 4, the lower end of the telescopic pipe 8 passes thro...

Embodiment 2

[0038]refer to Figure 6-7 The difference between this embodiment and Embodiment 1 is that the lifting device includes a limiting groove 23 jointly opened in the connecting column 5 and the bottom plate 4, the limiting groove 23 is slidingly connected to the limiting rod 24, and the inner top of the annular groove The wall is evenly provided with a plurality of side grooves 26, and an interlayer is formed between the side grooves 26 and the groove 1. The upper end of the interlayer is provided with an installation groove connected with the side grooves 26 and the groove 1, and two inner walls on both sides of the installation groove are rotated and installed. Guide wheel 25, and two guide wheels 25 are arranged corresponding to groove 1, side groove 26, and traction rope 27 is guided, and the inner bottom wall of annular groove is fixedly installed with small hoist 28, and the driving equipment of small hoist 28 adopts worm gear to reduce speed Machine, low speed and self-lock...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap