Gear shifting device

A gear switching and gear technology, which is applied in the field of gear switching devices, can solve the problems of occupying space, complicated assembly, and enlarged dimensions of electric tools, and achieves the effects of convenient assembly, simple structure and reliable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

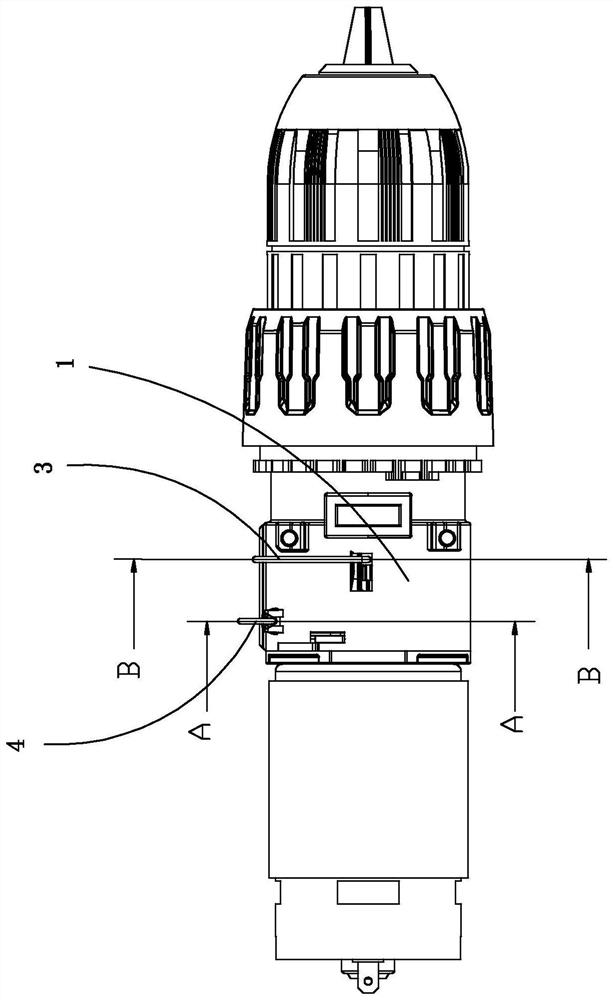

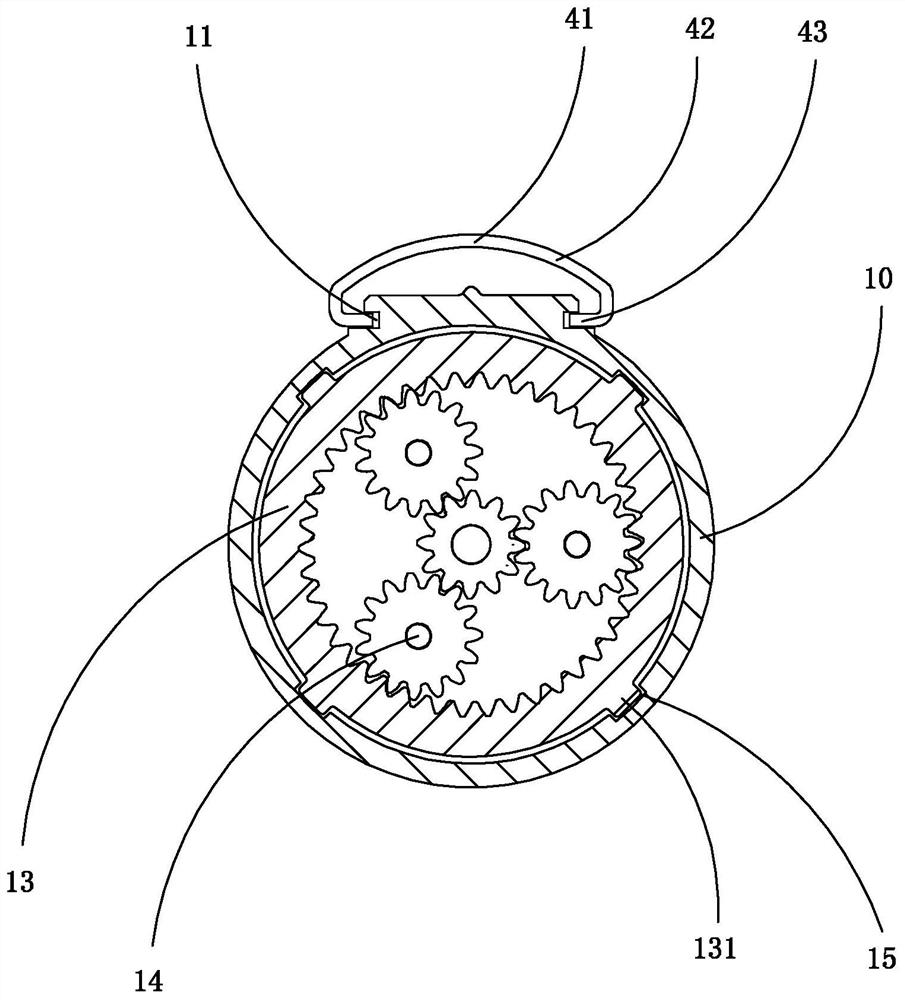

[0029] Such as Figure 1 to Figure 8 Shown is a gear switching device 100 related to the present invention, which is used for gear switching of two-stage transmission of electric tools and includes a gear box 1 , a shift push button 2 and a bow 3 . The shift push button 2 can move between the first gear and the second gear, the top 31 of the bow 3 is fixed on the lower part of the shift push button 2 and the bottom of the bow 3 is connected to the gear On the gearbox 1, the shift push button 2 drives the bow 3 to move relative to the housing 10 of the gearbox 1 to realize gear shifting.

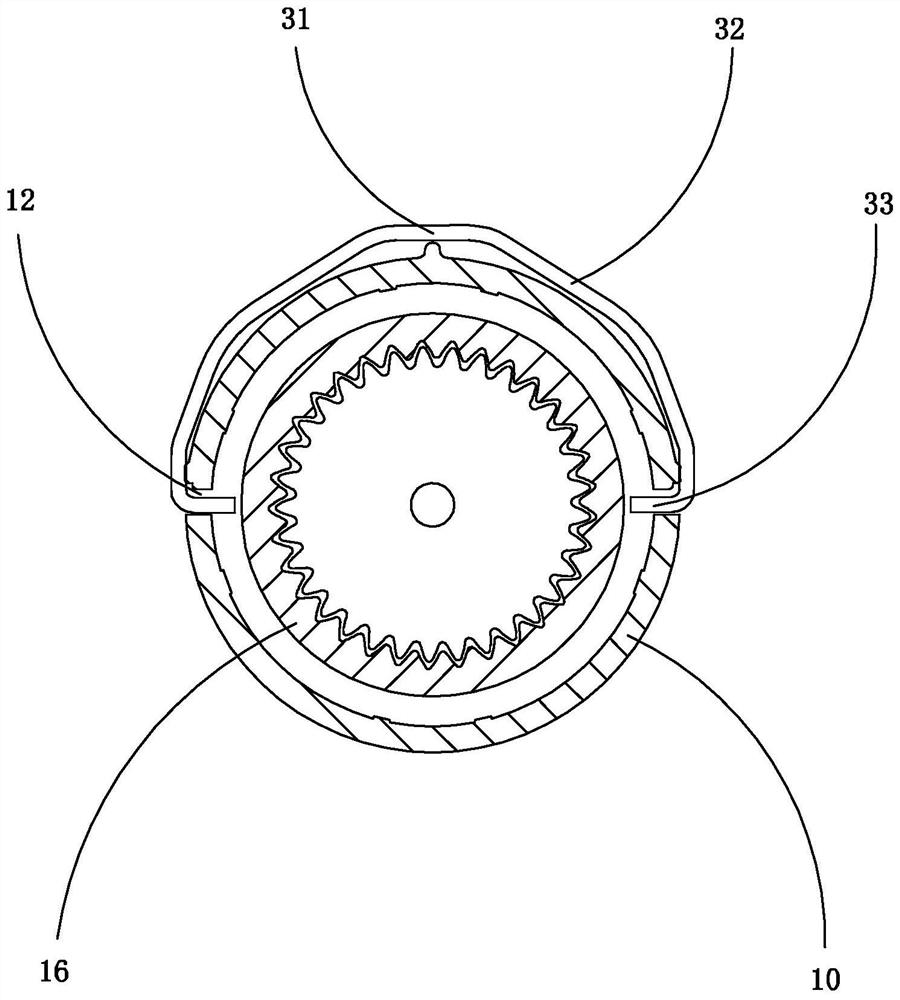

[0030] combine image 3 As shown, the bow 3 is made of metal wire and is provided with two elastic parts 32 extending obliquely downward from both ends of the top 31 and two extension parts 33 extending oppositely from the bottom ends of the two elastic parts 32. The component 3 straddles the housing 10 of the gear box 1 through two elastic parts 32 . The gear case 1 is provided with two t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com