Valve unit, valve assembly and method for checking closed state of valve unit

A technology of valve unit and valve closing, applied in the direction of parts in contact between valve elements and valve seats, engine elements, valve operation/release devices, etc., can solve problems such as low conductivity and achieve reliable leakage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

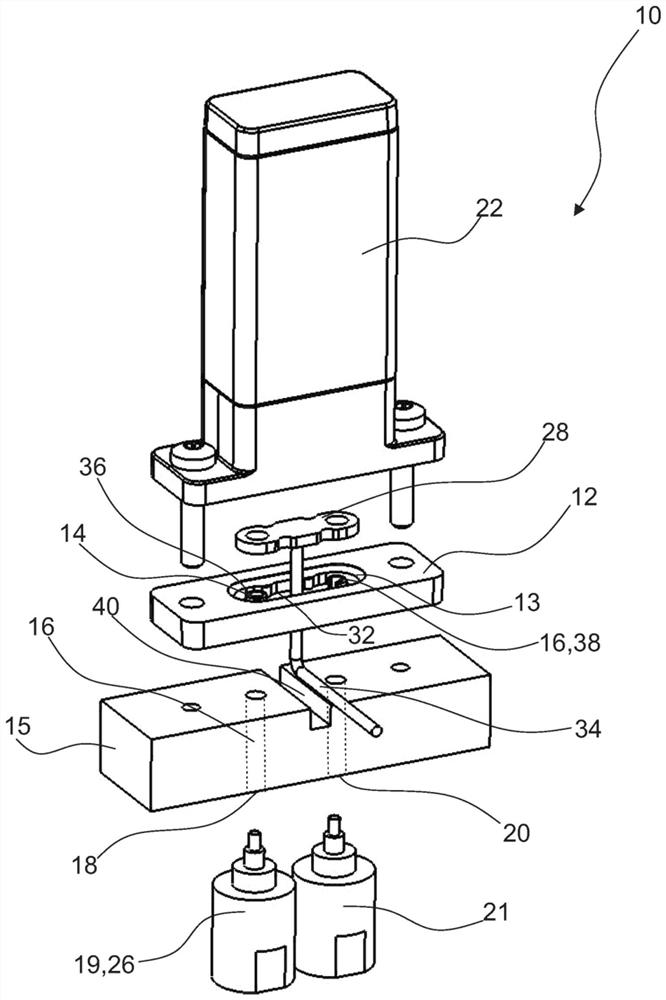

[0039] figure 1 A valve unit for metering fluids such as medical reagents is shown in an exploded view.

[0040] The valve unit 10 comprises a fluid housing 12 which has a valve seat 14 . The valve seat 14 is preferably integrally formed in the fluid housing 12 .

[0041] In particular, the valve seat 14 is arranged in a recess 13 in the fluid housing 12 .

[0042] The section of the fluid channel 16 runs in the fluid housing 12 from the fluid inlet 18 to the valve seat 14 and from there to the fluid outlet 20 .

[0043] exist figure 1 In the valve unit 10 illustrated in , the fluid housing 12 is arranged on an additional flange housing 15 . The fluid channel 16 continues in the flange housing 15 such that a fluid inlet 18 and a fluid outlet 20 are located on the flange housing 15 .

[0044] exist figure 1In the embodiment shown in , a flanged housing 15 for the valve unit 10 is shown. In practice, however, several valve units 10 are often required in a metering process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com