Rotary quick-locking type fluid connector assembly

A connector component and fluid technology, applied in the direction of couplings, mechanical equipment, etc., can solve the problems of not fully meeting user needs, fluid pressure loss, and large dimensions, and achieve technological progress and economic benefits, reduce plug-in Combined force and small form factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

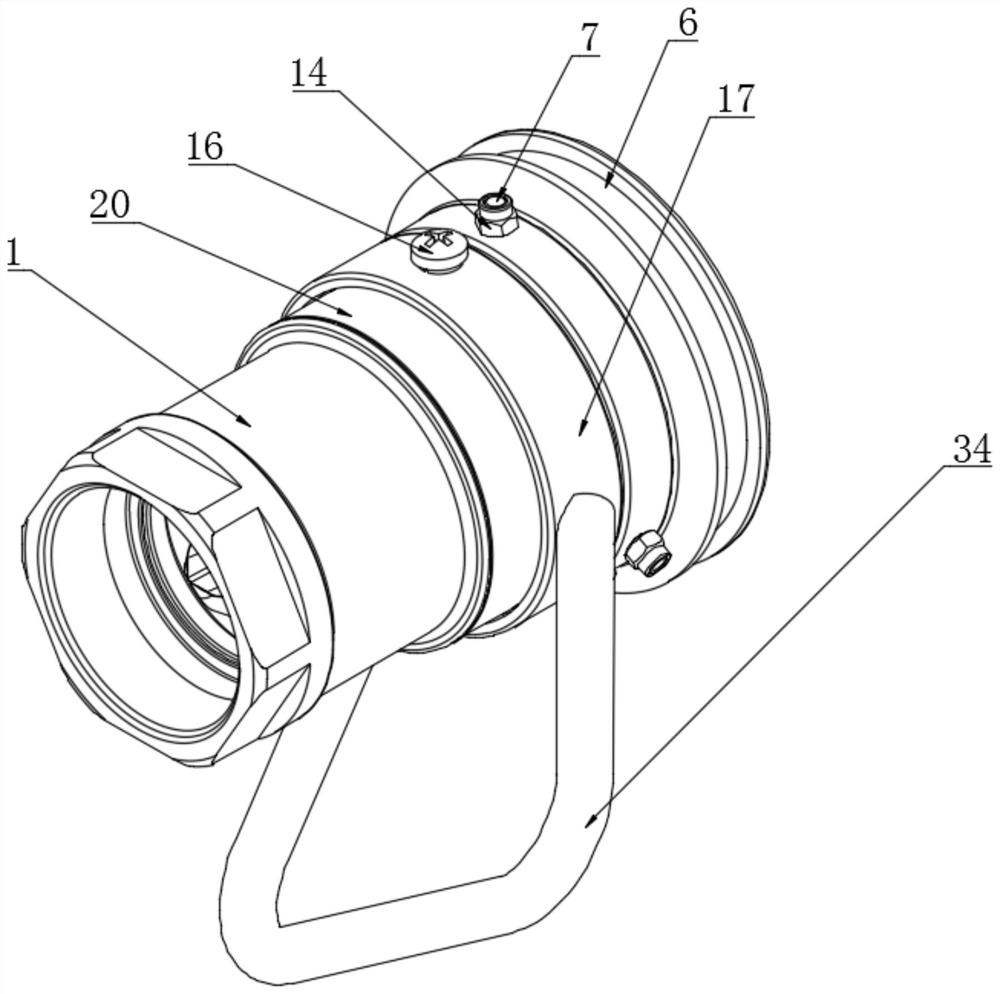

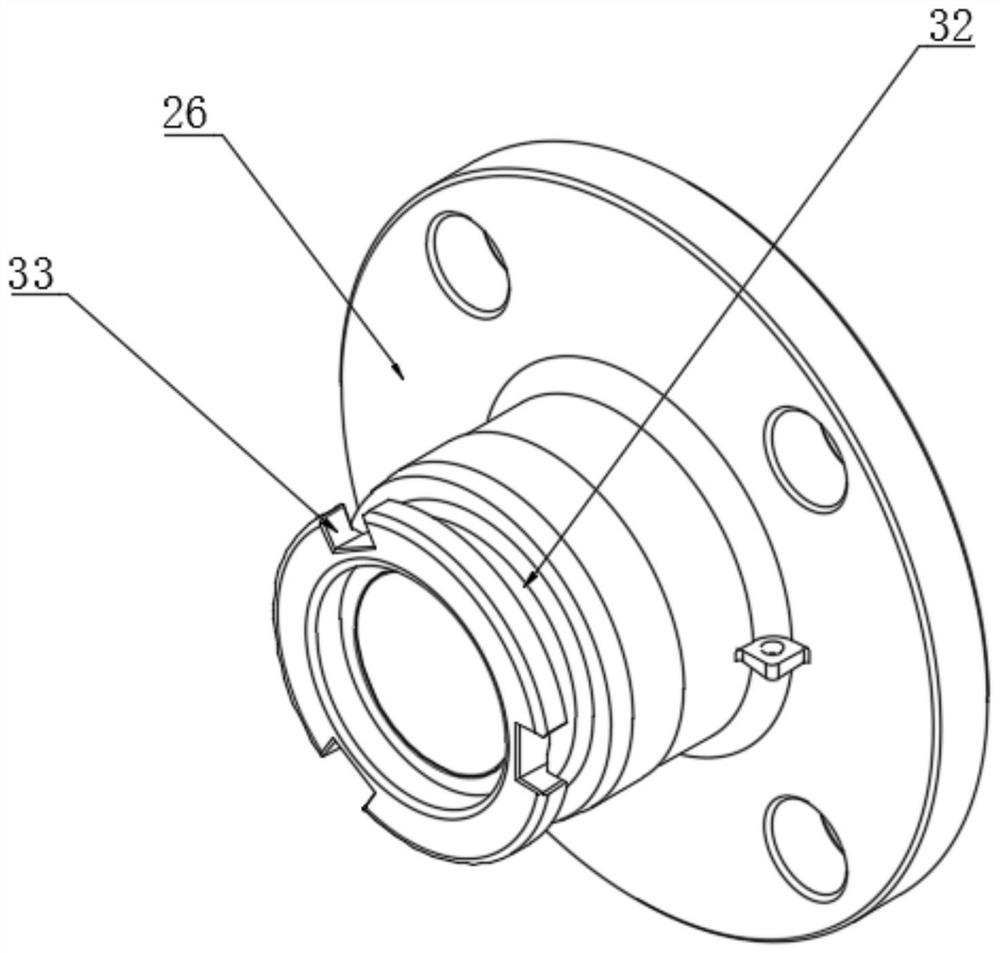

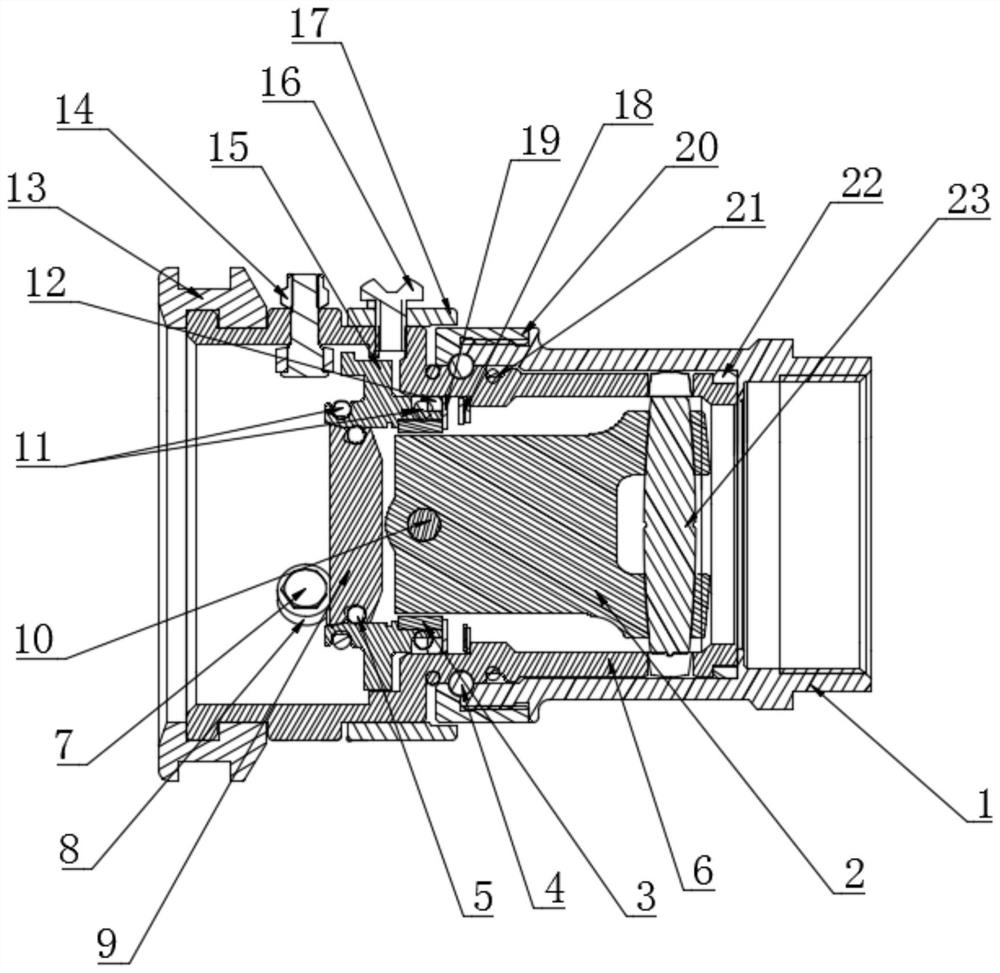

[0030] See Figure 1-11 The present invention provides a technical solution: a rotary quick lock fluid connector assembly comprising a plug and a socket, the plug inserted in the socket, the plug includes a plug housing Ⅰ1 disc housing and the plug disc Ⅱ20, round plug ⅱ20 disc housing is fixed between the outer surface of the plug housing ⅰ1 the disk, the disk housing ⅰ1 the plug and the plug housing ⅱ20 disk 19 is provided with a stainless steel spacer, the disc and the plug ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com