AC brake coil, winding device and process

A winding device and brake technology, which is applied in the directions of transformer/inductor coil/winding/connection, coil manufacturing, brake actuator, etc., can solve the problem of inconvenient coil installation, achieve the effect of convenient installation and avoid bad contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

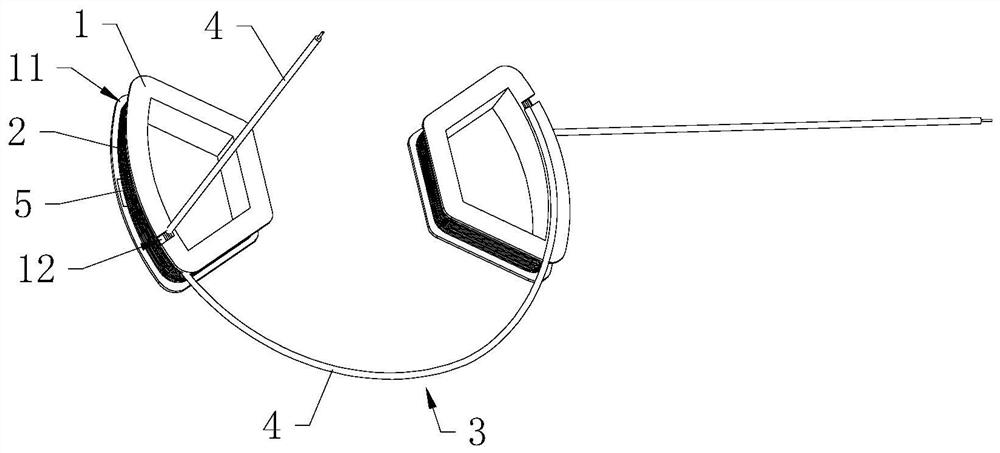

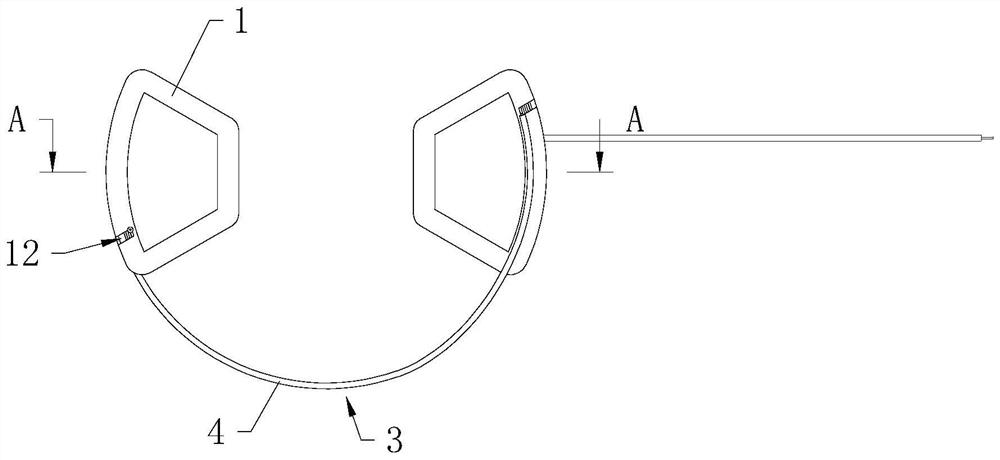

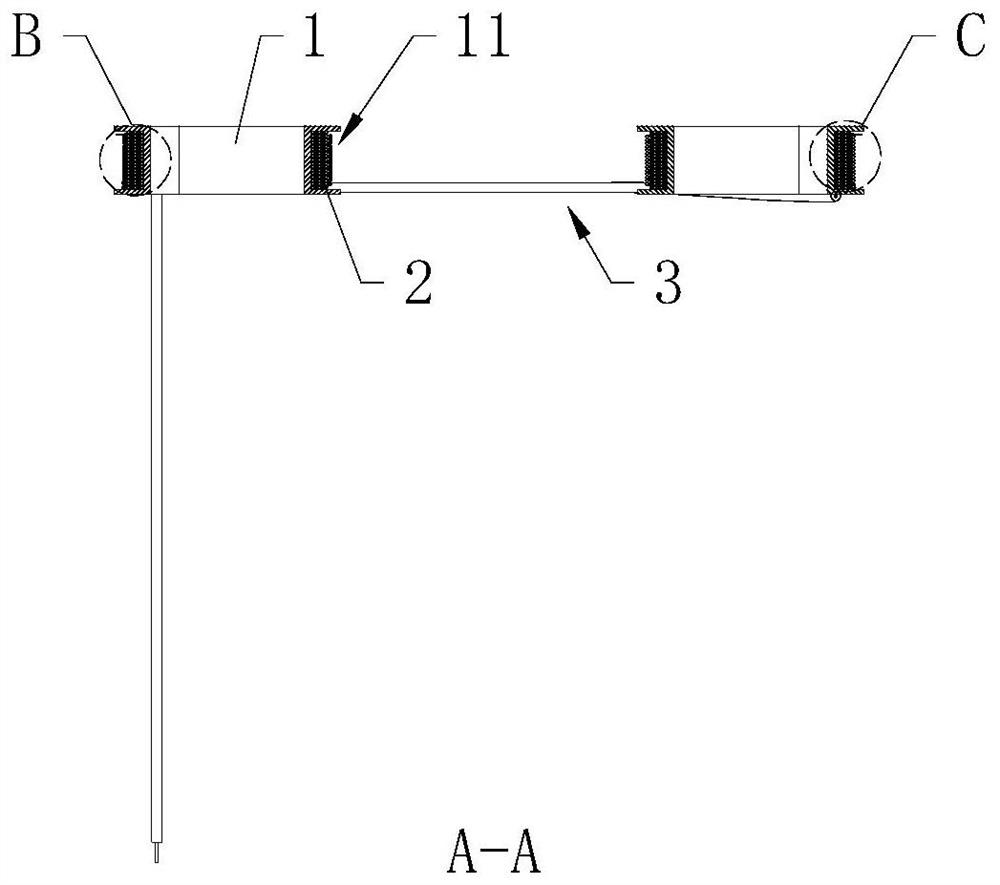

[0066] Attached to the following Figure 1-11 This application will be described in further detail.

[0067] The AC brake is usually powered by three-phase electricity. The electromagnet of the AC brake includes an iron core and six windings. The iron core is annular. One end of the iron core is provided with six mounting posts at intervals along its circumference, and the windings are wound by wires. Thus, one winding is sleeved on one mounting post, and two windings symmetrical with respect to the axis of the iron core form a group and are connected in series with each other.

[0068] The embodiment of the present application discloses an AC brake coil.

[0069] refer to figure 1 , the AC brake coil includes a skeleton 1, a winding 2 and a protective sleeve 4.

[0070] There are two skeletons 1. The outer circumference of any skeleton 1 is provided with a ring groove 11. The ring groove 11 extends along the circumferential direction of the skeleton 1 for a week. The ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com