Plate bending treatment device

A processing device and plate technology, applied in the field of plate processing, can solve the problems of small operation space and large occupation space for workers, and achieve the effect of diversifying plate bending and reducing occupation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

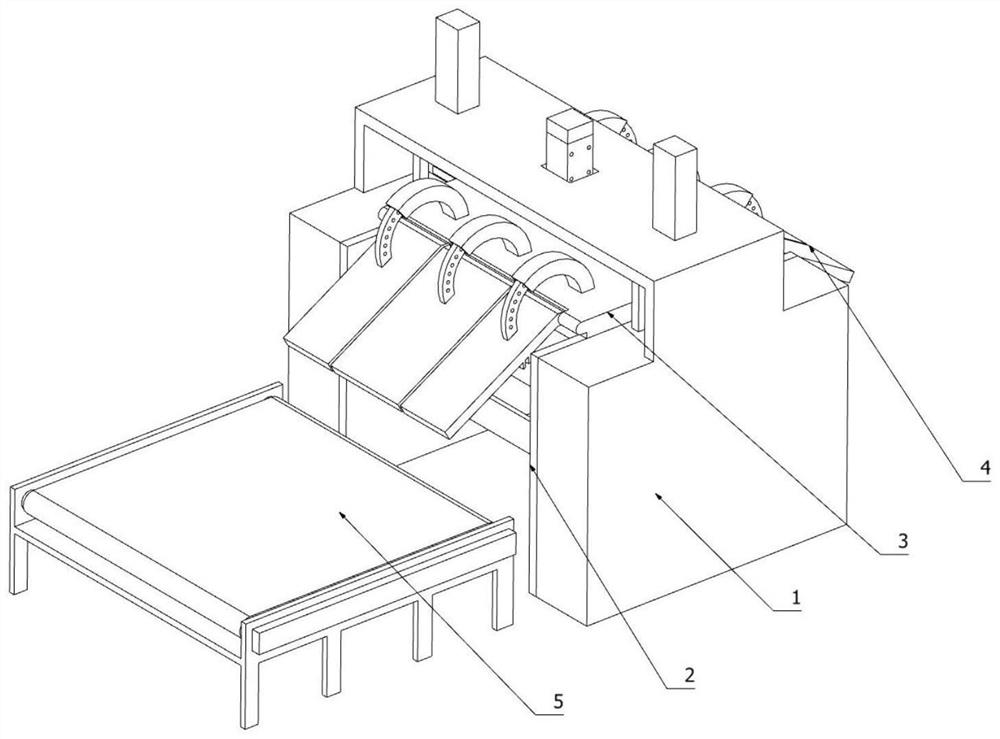

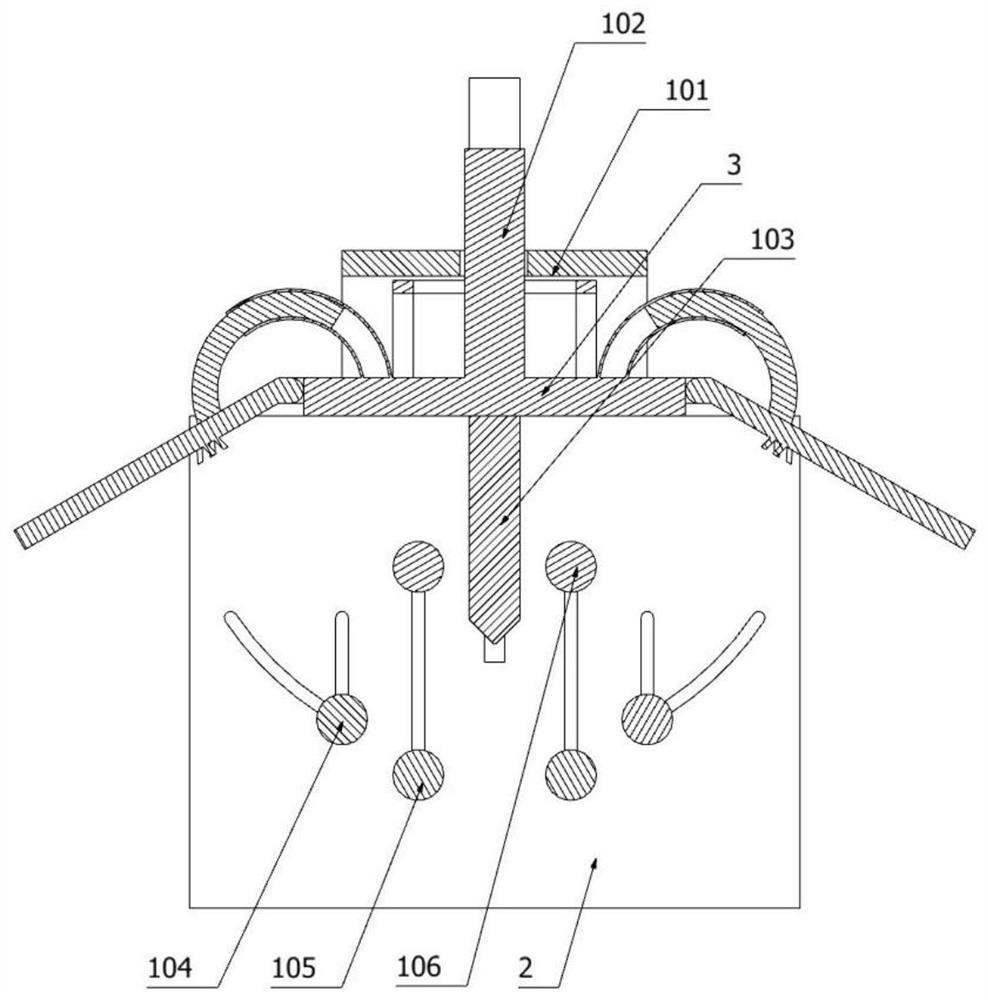

[0078] The present invention provides a plate bending processing device, which is characterized in that it includes: an outer casing 1, an inner casing 2, a cover 3, a roof 101, a conveyor 5, a first roller 104, a pressure head 103, a second The roller 105, the third roller 106, the cover plate mechanism 4, the outer casing 1 is arranged symmetrically; the inner casing 2 is fixed on the inner side of the outer casing 1; the cover plate 3 is fixed on the top of the inner casing 2; the top plate 101 is set On the top of the cover plate 3, both sides of the top plate 101 are fixed on the outer casing 1; the conveyor 5 is arranged in front of the outer casing 1, and the conveyor 5 is used to transport the boards; the pressure head 103 is arranged under the middle of the cover plate 3 ; The first roller 104 is arranged between the inner boards 2, and is symmetrically arranged front and rear; the second roller 105 is arranged between the inner boards 2, and is arranged symmetrically ...

Embodiment 2

[0087] Same as Embodiment 1, the present invention also includes:

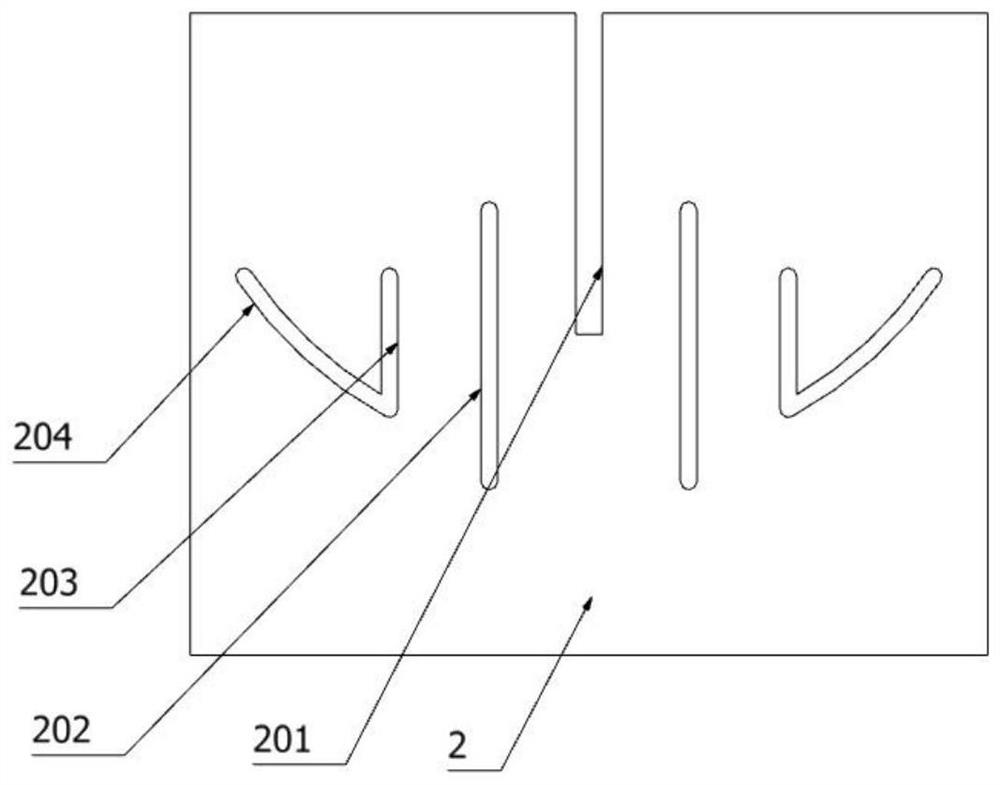

[0088] The first set of plates 401 is located between the cover plates 3 , and the second set of plates 402 is located on both sides of the first set of plates 401 of the cover plates 3 .

[0089] The bottom surface of the first set of boards 401 is provided with a straight buckle groove 4011, which is used for clamping a right-angle plate, and the bottom surface of the second set of boards 402 is provided with an arc buckle groove 4021, which is used for clamping an arc-shaped board .

[0090] The top of the first set of plates 401 and the second set of plates 402 is provided with an arc-shaped guide rod 404, and the top of the cover plate 3 is provided with an arc-shaped track 403. The arc-shaped guide rod 404 is arranged in the arc-shaped track 403, and the arc-shaped guide rod 404 and arc track 403 are arranged in two rows, and each row has three.

[0091] Both sides of the arc-shaped guide rod 404 are p...

Embodiment 3

[0094] The present invention also provides a bending method of a plate bending processing device, comprising:

[0095] When bending a right-angle plate, the plate is transported to the inner panel 2 by the conveyor 5. After the position of the plate is adjusted, the hydraulic cylinder is used to drive the pressure head 103 down to press and bend the middle of the plate, and then the second cylinder is used to press and bend the plate. 215 drives the third connecting rod 214 to rise, and the arc drag heads at the two ends of the third connecting rod 214 hold up the first gear 211 and rise together with the second gear 213. The first gear 211 and the second gear 213 are on the The tooth openings on both sides of a connecting rod are meshed and driven, and the first roller 104 and the second roller 105 are raised together, and the two sides of the plate are pressed and bent upwards. When the hydraulic cylinder and the second cylinder 215 reach a distance of The right-angle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com