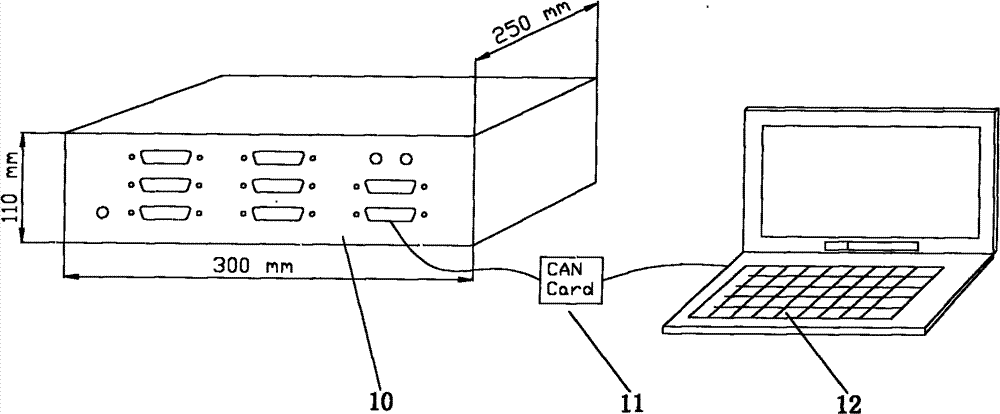

Control device of automotive air conditioning electrical equipment and using method thereof

A control device, a technology for automotive air conditioners, applied in heating and ventilation control systems, applications, household heating, etc., can solve problems such as inability to work with temperature servo motors, inability to control electrical devices, and inconvenience for testing and simulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

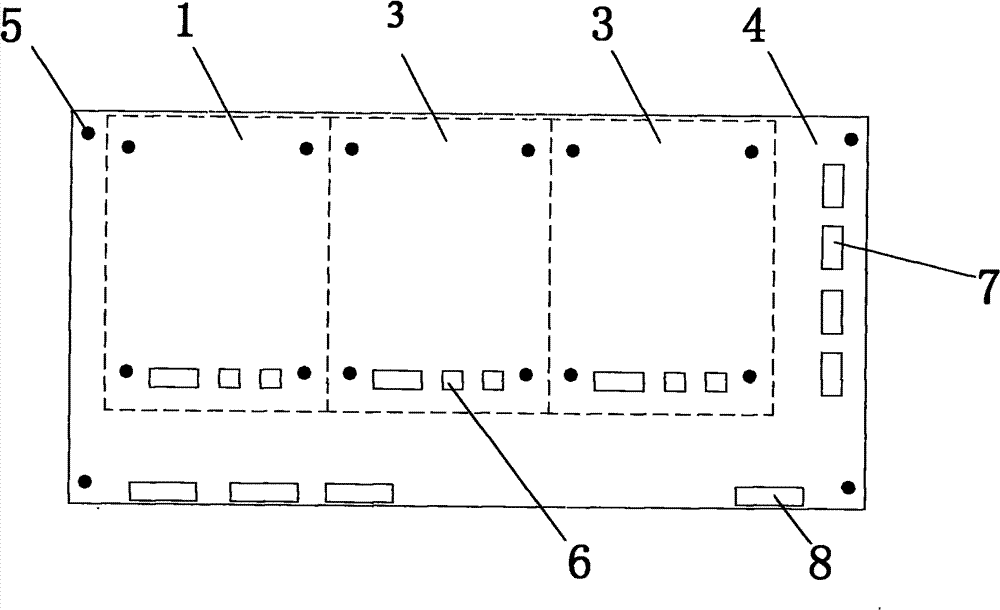

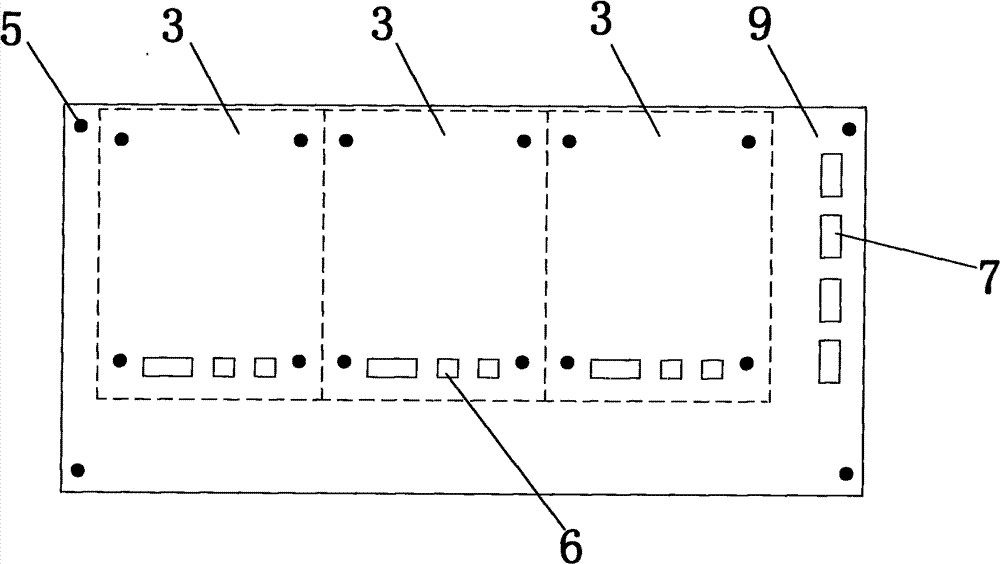

Embodiment 1

[0052] In this embodiment, a functional board 3 is connected to and controls a DC servo motor with a potentiometer. When in use, input the parameters that need to be set into the interface, and after the control box processes these parameters, the motor will run, display relevant parameters, and obtain the results required by the user.

[0053] The control principle of the function board with potentiometer servo motor used in this embodiment is as follows: Figure 6 As shown, the motor rotates, drives the brush through the transmission gear, and the brush touches the potentiometer on the circuit board to form an H bridge through Q1, Q2, Q3, and Q4. When MCU-C1 and MCU-C2 are 10 or 01 respectively, the control Motor forward and reverse. Resistor R1 is used for current collection, and the collected signal is used for motor control.

[0054] Such as Figure 10 As shown, the working process of the function board with potentiometer servo motor is as follows: determine the forwar...

Embodiment 2

[0056] In this embodiment, a functional board 3 is connected to and controls a DC servo motor with contacts. When in use, input the parameters that need to be set into the interface, and after the control box processes these parameters, the motor will run, display relevant parameters, and obtain the results required by the user.

[0057] The control principle of the functional board of the DC servo motor with contacts used in this embodiment is as follows: Figure 7 As shown, resistor R1 is used for current collection, and the collected signal is used for motor control.

[0058] Such as Figure 11 As shown, the working process of the function board of the DC servo motor with contacts is as follows: determine the corresponding contacts of each point; click the required contact signal button; judge whether the current is greater than the stall current, if so, emergency stop, If not, the motor runs.

Embodiment 3

[0060] In this embodiment, a function board 3 is connected to and controls a temperature sensor, and the function board 3 is an analog acquisition board. Such as Figure 12 As shown in , the analog acquisition board collects the resistance value of the temperature sensor, so as to judge whether the working state of the temperature sensor is normal, short circuit or open circuit. The steps are as follows:

[0061] 1) Collect the resistance value of the temperature sensor;

[0062] 2) Determine whether the resistance value is in the normal range, if the resistance value is in the normal range, if the resistance value is in the normal range, the temperature sensor is working normally; if the resistance value is zero, the temperature sensor is short-circuited; if the resistance value is infinite, the temperature sensor Sensor open circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com