Automatic press-fitting device for gearbox output shaft

A technology of press-fitting device and output shaft, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of low degree of automation, difficult control of press-fitting force and stroke, and large transmission torque, so as to save manpower and energy saving The effect of manual and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

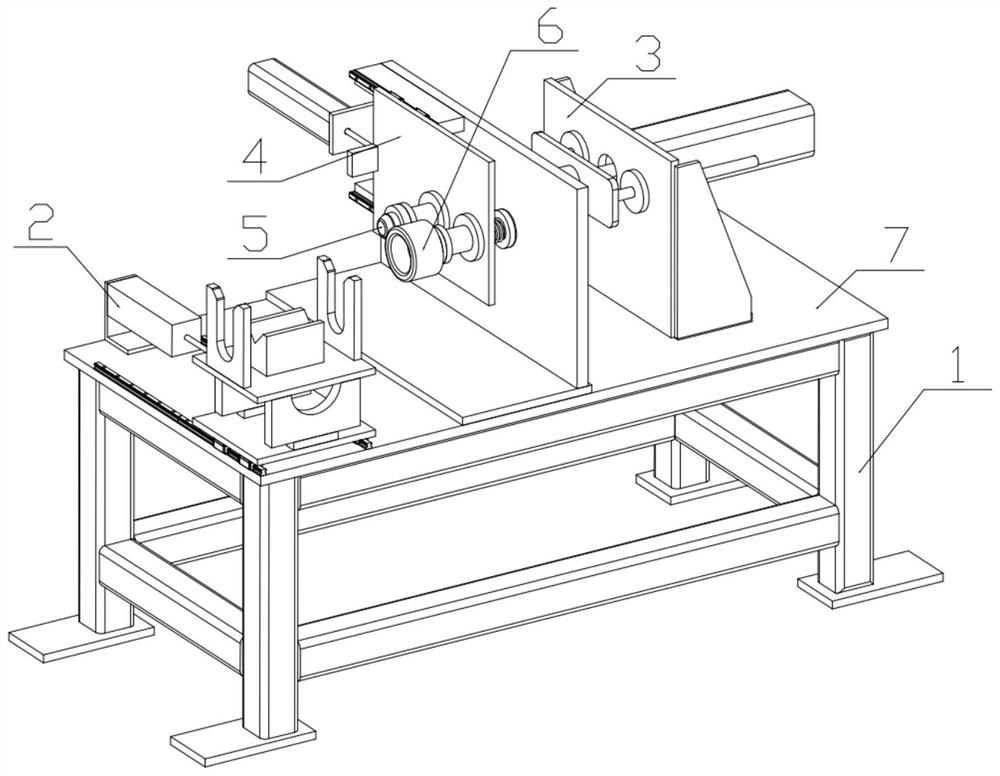

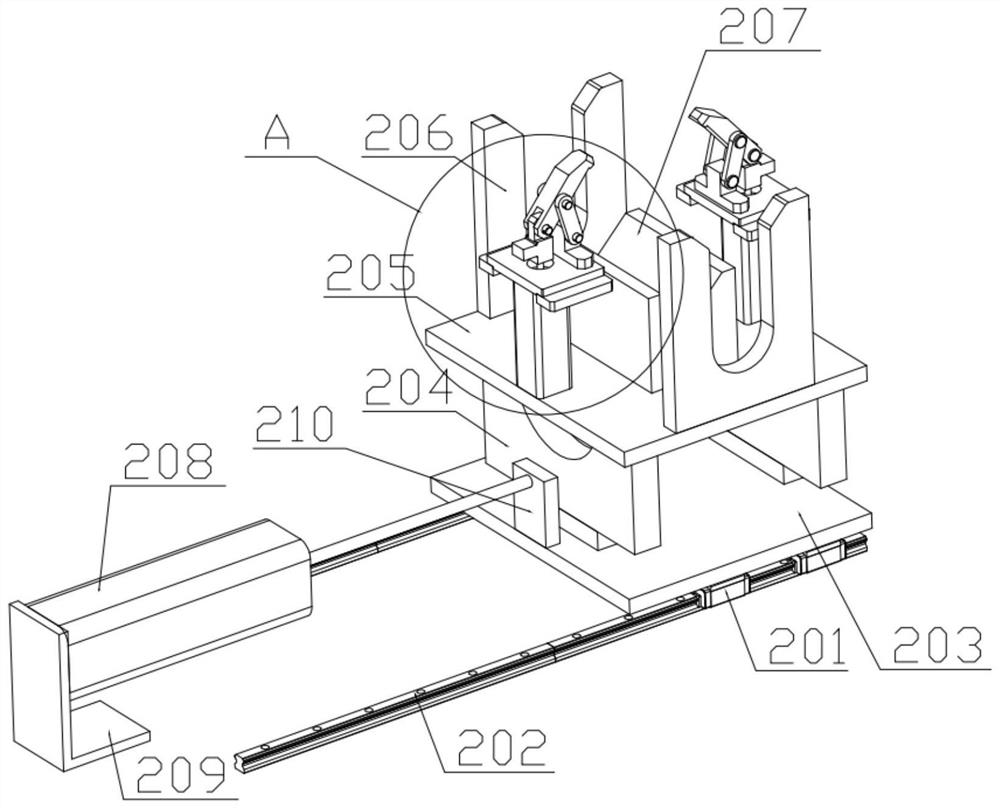

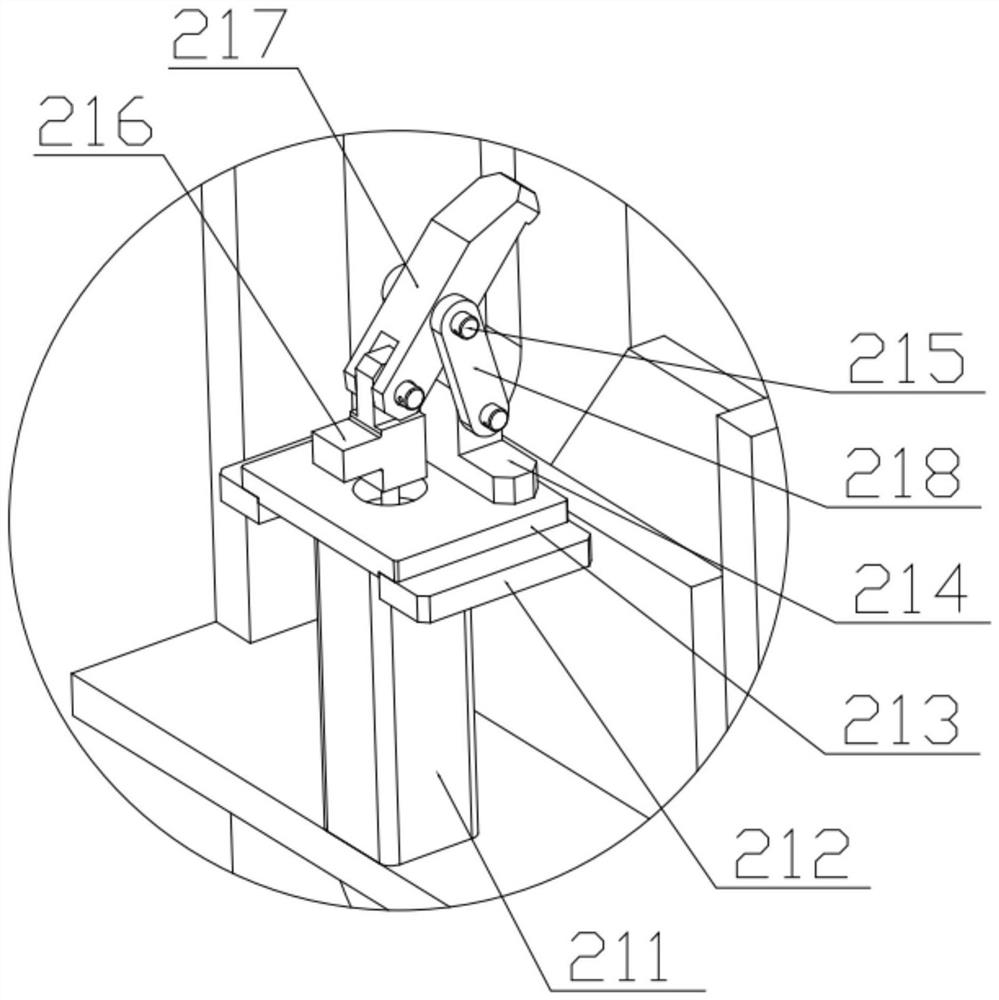

[0027] Attached below Figure 1-7 The present invention is described in detail below.

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, an automatic press-fitting device for the output shaft of a transmission, including a fixed installation base 1, an output shaft conveying device 2, a press-fitting device 3, a pressure head switching device 4, a bearing inner ring press-fitting pressure head 5, a bearing outer ring pressure Install the pressure head 6, install the fixed plate 7, the upper surface of the fixed installation base 1 is installed and fixed to install the fixed plate 7, the upper surface of the installed fixed plate 7 is installed and fixed the output shaft conveying device 2, and the left side of the output shaft conveying device 2 and The left side of the installation fixed plate 7 is aligned, and the rear side of the output shaft transport device 2 is also aligned with the rear side of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com