Electro-thermal knife device for wrapping material high-temperature electro-thermal film

一种包装材料、电热刀的技术,应用在金属加工等方向,能够解决不方便钻孔操作、电热钻孔操作效率低等问题,达到提高效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

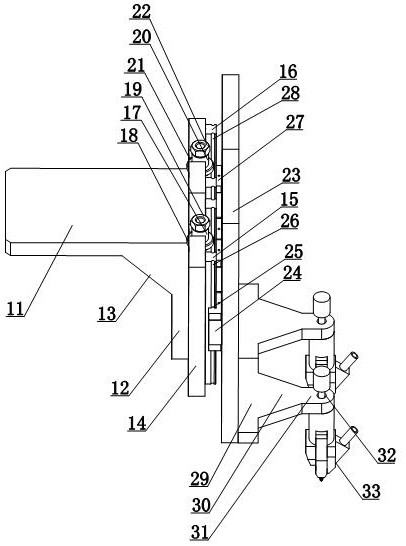

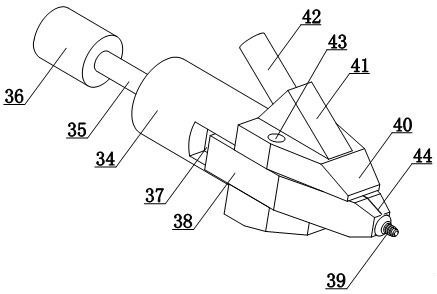

[0017] like figure 1 and figure 2 As shown, the electric heating knife device used for high-temperature electric heating film of packaging materials includes a fixed plate 11, the front of the fixed plate 11 is provided with a side plate 12, and a connecting block 13 is provided between the side plate 12 and the front of the fixed plate 11, The front portion of the side plate 12 is provided with a base plate 14, the front side of the base plate 14 is provided with a first guide rail 15, and the other side of the front face of the base plate 14 is provided with a second guide rail 16; the top side of the base plate 14 is provided with a first fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com