Dry branch treatment equipment for municipal garden cleaning and treatment method

A technology for processing equipment and dead branches, which is applied in the field of dead branch processing equipment and processing for municipal garden cleaning. It can solve the problems of easy breakage of the tip of branches, different lengths of branches, and falling of branches, so as to improve transmission stability and reduce material loss. Simple and convenient, increase the effect of closed time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

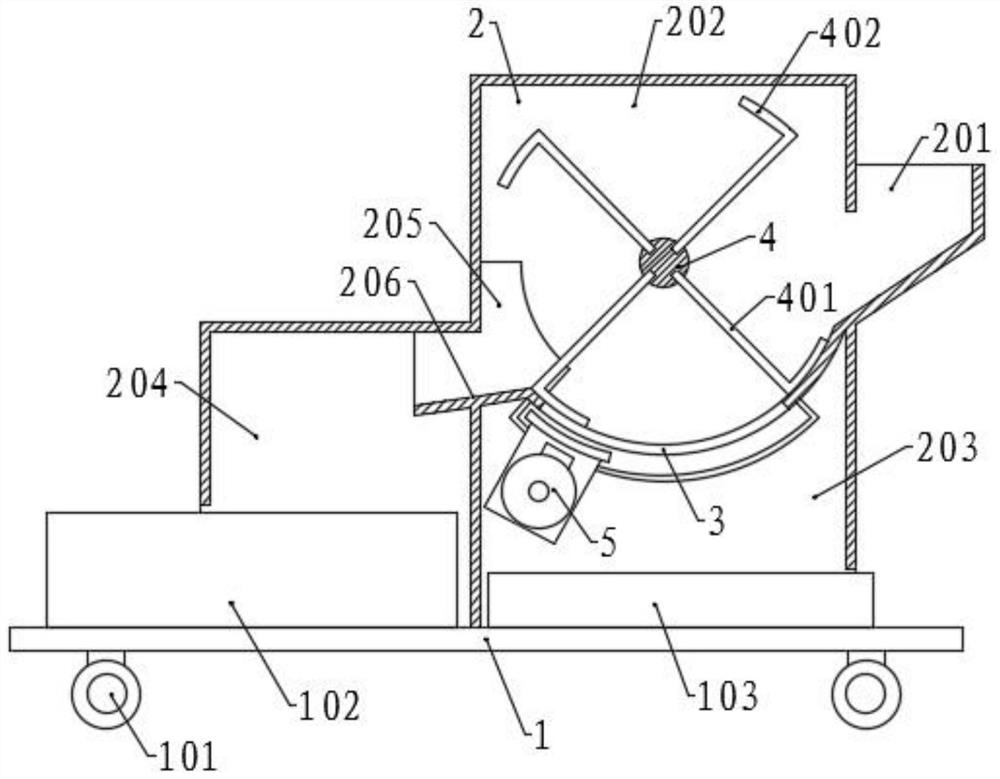

[0056] Please refer to the accompanying drawings, the present invention provides a technical solution: a kind of dead branch processing equipment for municipal garden cleaning, including a base 1, the four corners of the bottom surface of the base 1 are provided with moving wheels 101, and a stepped fixed box 2 is fixed on the top surface , and the right side of the top surface of the fixed box 2 is higher than the left side of the top surface, the upper right side of the fixed box 2 is provided with a rotating chamber 202, the lower part of the right side is provided with a collection chamber 203, and the left side is provided with a feeding chamber 204, and the rotation An arc-shaped partition 3 is fixed between the cavity 202 and the collection cavity 203, and a feed hopper 201 is provided on the upper right side wall of the fixed box 2, and the bottom of the feed hopper 201 communicates with the rotating cavity 202;

[0057] A rotating assembly is provided in the rotating c...

Embodiment 2

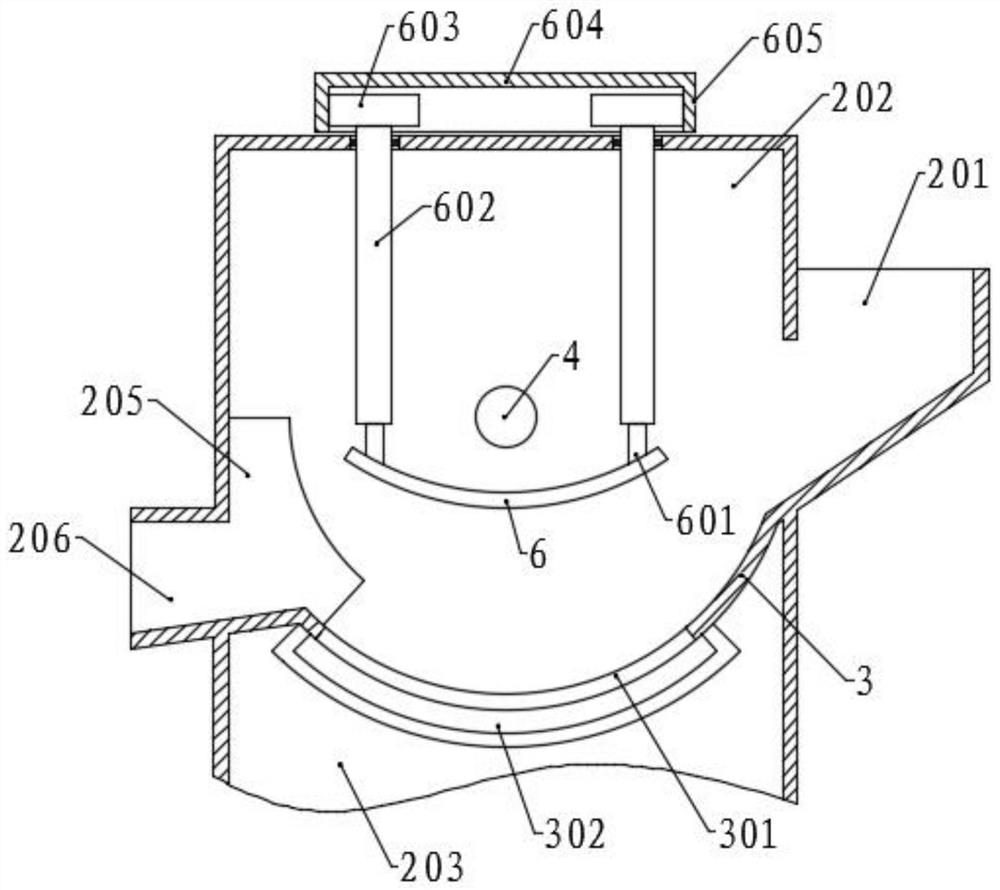

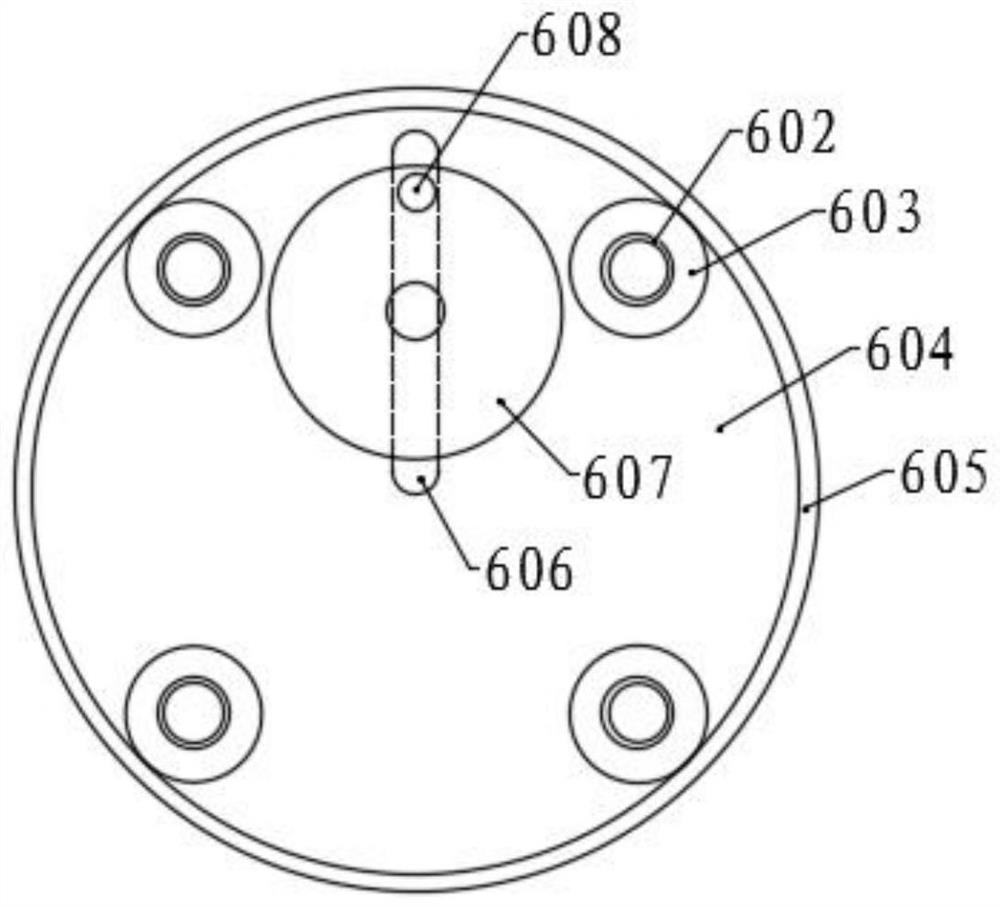

[0069] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the two symmetrical cutting grooves 301 in the lower part of the rotating cavity 202 are provided with a pressure plate 6, and the pressure plate 6 is located on the outside of the rotating plate 401 and at the center of the rotating shaft 4. Below, two vertical threaded shafts 601 are symmetrically fixed on the top surface of the pressure plate 6, and the threaded shaft 601 is threaded with a threaded cylinder 602, which is rotatably connected with the top surface of the fixed box 2, and the top end protrudes from the fixed box 2. Rotating gears 603 are fixed, and the outer sides of the four rotating gears 603 are meshed with a ring gear 605. The top of the ring gear 605 is fixed with a circular plate 604, and the circular plate 604 is provided with a connecting groove 606 along the radial direction. The top surface of the fixed box 2 is rotatably connected with a rota...

Embodiment 3

[0072] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a collecting hopper is fixed below the corresponding moving groove 7 in the collecting chamber 203, a pulverizing assembly is arranged below the collecting hopper, and the second collecting box 103 is located in the pulverizing assembly. Below, the crushing assembly includes two crushing shafts 8 that are symmetrically and parallelly arranged. The crushing shaft 8 is rotatably connected with the side wall of the fixed box 2, and one end extends out of the fixed box 2, and is fixed with a crushing gear 801. The two crushing gears 801 Mesh with each other, and one of the crushing gears 801 is also connected with a motor, and the smaller dead branches remaining after cutting are crushed through the crushing assembly for subsequent recycling.

[0073] Implementation four

[0074]The structure of this embodiment is basically the same as that of Embodiment 1. The difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com