Elastic putty material and preparation method thereof

A technology of elastic putty and elastic latex, which is applied in the direction of filling slurry, etc., can solve the problems of small elastic effect, high price and cost, and long production cycle, so as to increase elastic effect and stretch deformation effect, enhance elastic effect, Buffer impact weakening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

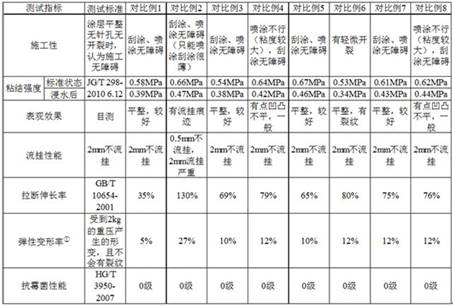

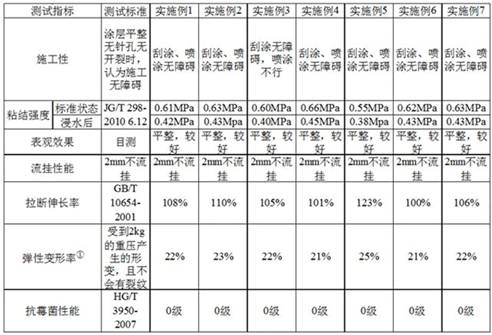

Examples

preparation example Construction

[0095] A preparation method of elastic putty material, comprising the following steps:

[0096] Mix elastic latex powder, rubber powder, diatomaceous earth and calcium carbonate whiskers;

[0097] The parts by weight of the elastic latex powder are 10 parts-15 parts; the parts by weight of the rubber powder are 15 parts-30 parts; the parts by weight of diatomaceous earth are 15 parts-25 parts; Servings - 20 servings.

[0098]A method for using an elastic putty material, comprising the following steps:

[0099] Mix the elastic putty material and water, let it stand after stirring, and stir again.

Embodiment 1

[0103] This embodiment provides an elastic putty material and its preparation method and use method, the steps are as follows:

[0104] In weight percentage, weigh 12.5% vinyl acetate / ethylene copolymerized elastic latex powder, 17.5% heavy calcium, 15% calcium carbonate whiskers, 10% talcum powder, 22.5% rubber powder, 20% diatomaceous earth, 0.5% Hydroxypropyl methylcellulose ether, 0.5% defoamer, 1% water repellent, 0.5% antifungal agent.

[0105] Preparation method: Pour the above-mentioned raw materials into the mixing equipment, mix them evenly, carry out weighing and packaging, and obtain the elastic putty material.

[0106] Method of use: by weight, mix 100 parts of the above-mentioned elastic putty material with 40 parts of water, stir with a mixer at high speed for 10 minutes, then let stand for 20 minutes, and then stir for 5 minutes.

Embodiment 2

[0108] This embodiment provides an elastic putty material and its preparation method and use method, which are basically the same as in Embodiment 1, the only difference being that the amount of vinyl acetate / ethylene copolymerized elastic latex powder and heavy calcium is different, and the steps are as follows:

[0109] In weight percentage, weigh 15% vinyl acetate / ethylene copolymerized elastic latex powder, 15% heavy calcium, 15% calcium carbonate whiskers, 10% talcum powder, 22.5% rubber powder, 20% diatomaceous earth, 0.5% Hydroxypropyl methylcellulose ether, 0.5% defoamer, 1% water repellent, 0.5% antifungal agent.

[0110] Preparation method: Pour the above-mentioned raw materials into the mixing equipment, mix them evenly, carry out weighing and packaging, and obtain the elastic putty material.

[0111] Method of use: by weight, mix 100 parts of the above-mentioned elastic putty material with 40 parts of water, stir with a mixer at high speed for 10 minutes, then let ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap