Anti-seepage water stop structure on water conservancy project

A water conservancy project and water-stop technology, which is applied in the field of anti-seepage and water-proof structures, can solve the problems of inconvenient maintenance of the filter plate and the inability of the water-stop plate to discharge water in time, and achieve the effects of easy cleaning, water discharge, and water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

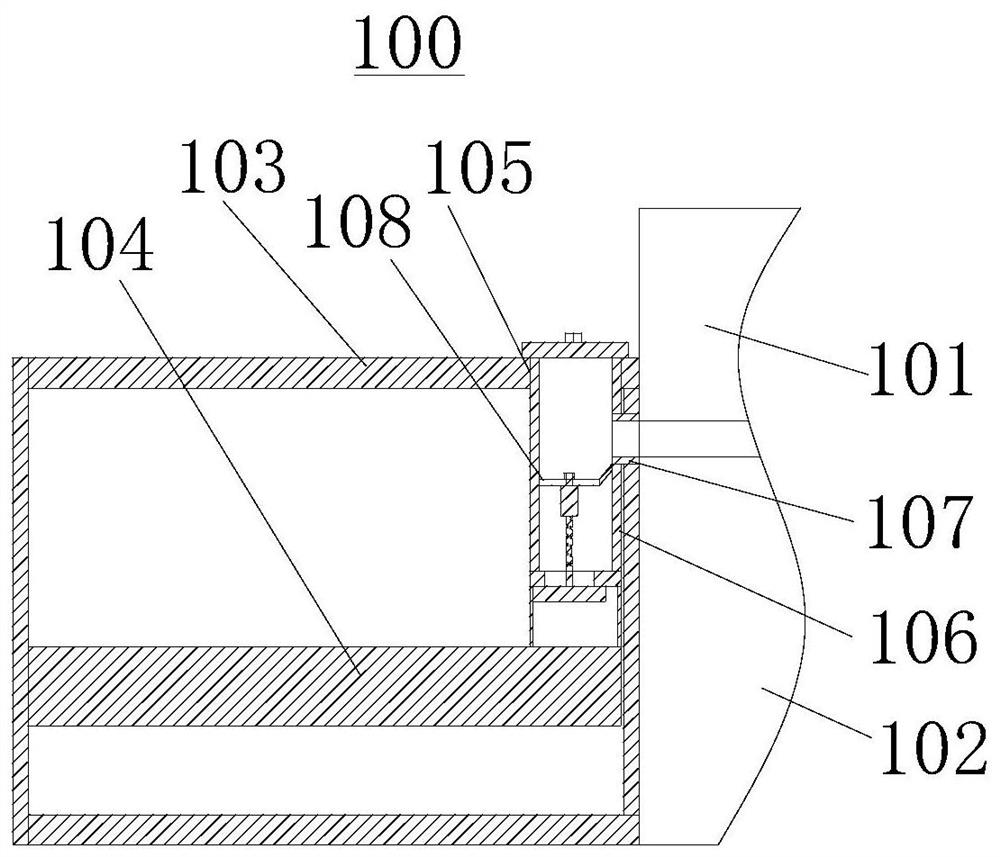

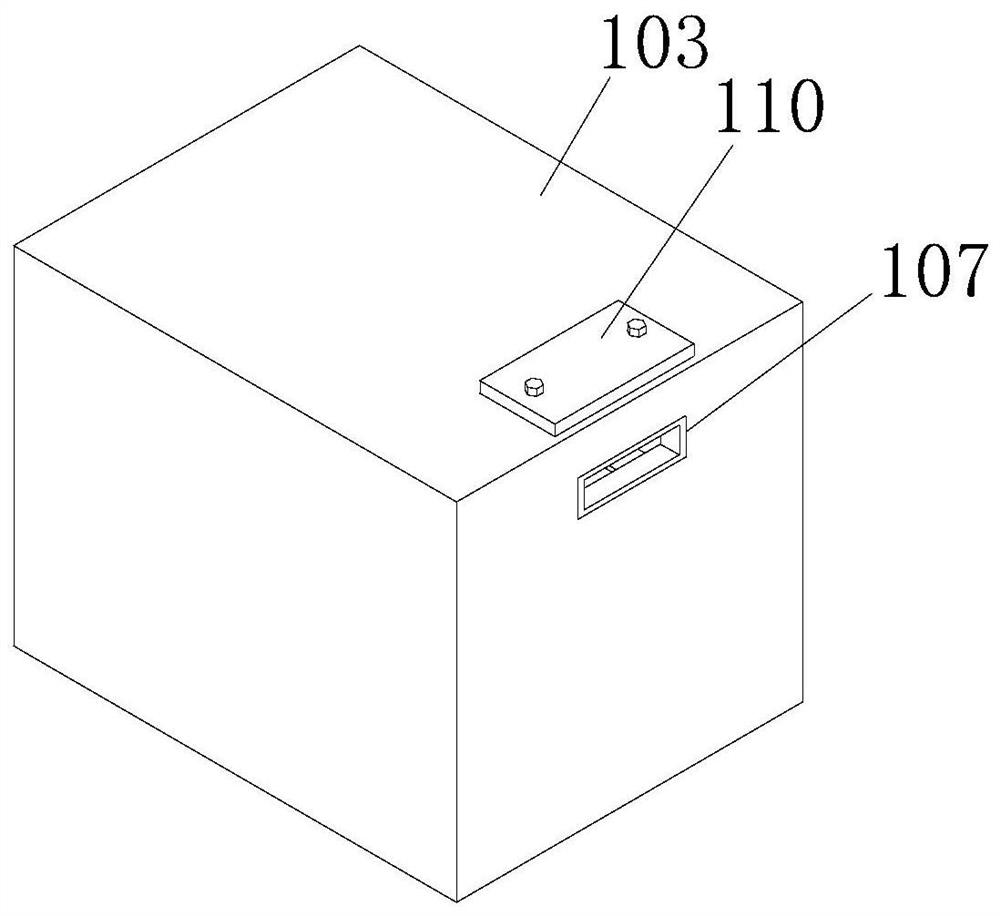

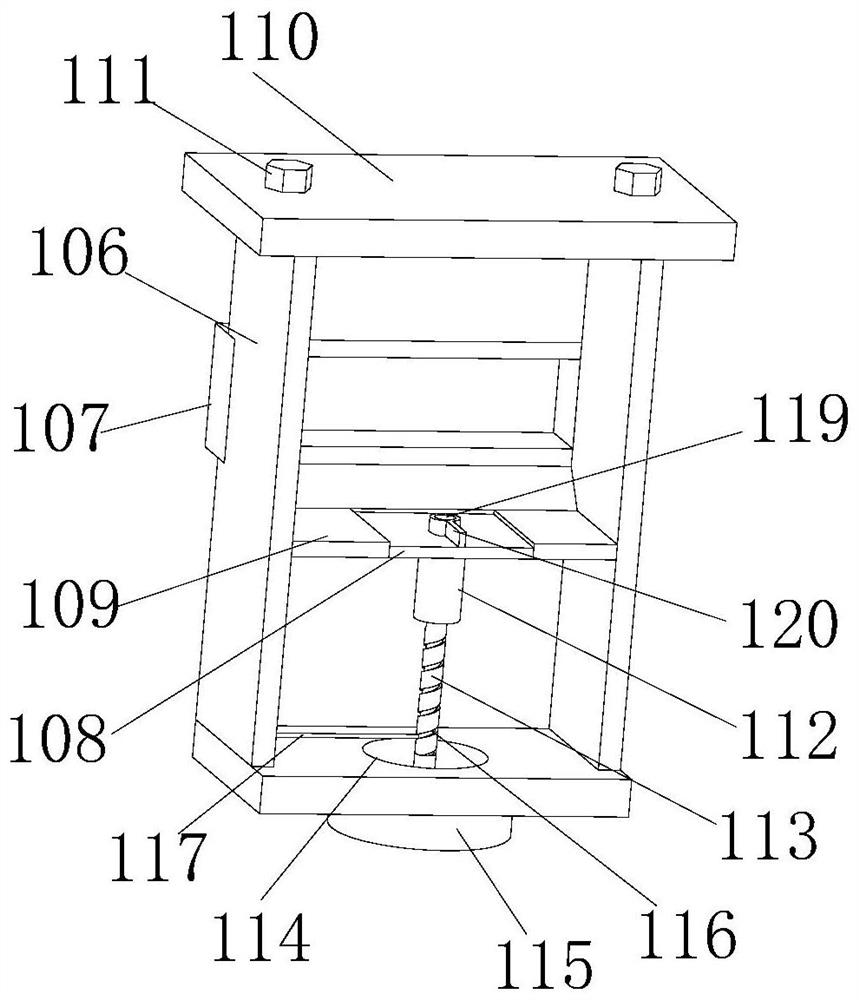

[0039] Please refer to Figure 1-5 , the present embodiment provides an anti-seepage and water-proof structure 100 in hydraulic engineering, which can ensure that the filter plate 108 is unblocked in real time during the working process, and at the same time, the water-stop plate 115 is vertically arranged to facilitate water discharge, so it has overall Strong industrial applicability and practicality.

[0040] Further specifically, the anti-seepage and water-proof structure 100 provided in this embodiment includes a concrete layer 101, the bottom side of the concrete layer 101 is fixedly installed with a waterproof board 102 for waterproofing, and the concrete layer 101 and the waterproof board 102 The same water tank 103 is fixedly installed on one side, and a material box 104 is arranged in the water tank 103 .

[0041]Further, a jack 105 is provided on the water tank 103, and a filter box 106 is plugged into the jack 105. The bottom side of the filter box 106 is in conta...

no. 2 example

[0059] Please refer to Figure 6-7 and in the first example Figure 1-5 , this embodiment provides an anti-seepage and water-proof structure 200 on hydraulic engineering, which is roughly the same as the anti-seepage and water-proof structure 100 on hydraulic engineering provided in the first embodiment, the difference is that the cleaning structure in this embodiment Component 220 is different.

[0060] Specifically, in the anti-seepage and water-proof structure 200 of the water conservancy project in this embodiment, three sets of cleaning structure assemblies 220 are provided, and the three sets of cleaning structure assemblies 220 are arranged around the circumferential array of the rotating rod 119 . It should be noted that such a setting is to speed up the cleaning efficiency of the cleaning structural assembly 220 and reduce the workload of a single cleaning structural assembly 220, so that the use of a single cleaning structural assembly 220 can be extended while impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com