Organic-inorganic hybrid paraffin/silicon dioxide/modified illite powder phase change microcapsule as well as preparation method and application thereof

A phase change microcapsule, silica technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of low foam tear strength, high foam density, and uneven cells. To achieve the effect of superior durability and stability, good thermal insulation performance, easy flow and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of paraffin / silicon dioxide / modified illite powder phase change microcapsules is as follows:

[0047] S1. Use gravity separation method to separate illite to obtain purified illite (the main method is: add 2g illite to 40mL of distilled water, continue magnetic stirring after ultrasonication to make it evenly dispersed, use plastic wrap for the beaker After sealing, let stand, discard the supernatant, transfer the intermediate suspension and bottom impurities to a desktop centrifuge for solid-liquid separation. After drying, the purified illite is obtained);

[0048]S2. Take 0.1 g of sodium carbonate as the sodium modification agent, and after obtaining sodium-based modified illite, add 0.5 g of cetyltrimethylammonium bromide, continue stirring at 80 °C for 7 hours, and finally dry at 100 °C, That is to obtain modified illite;

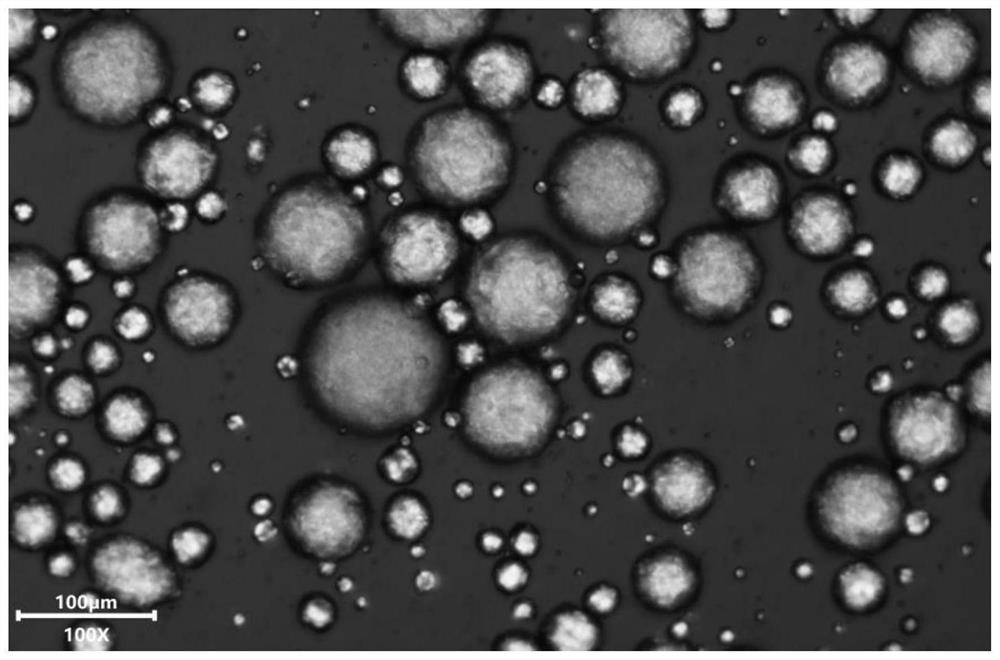

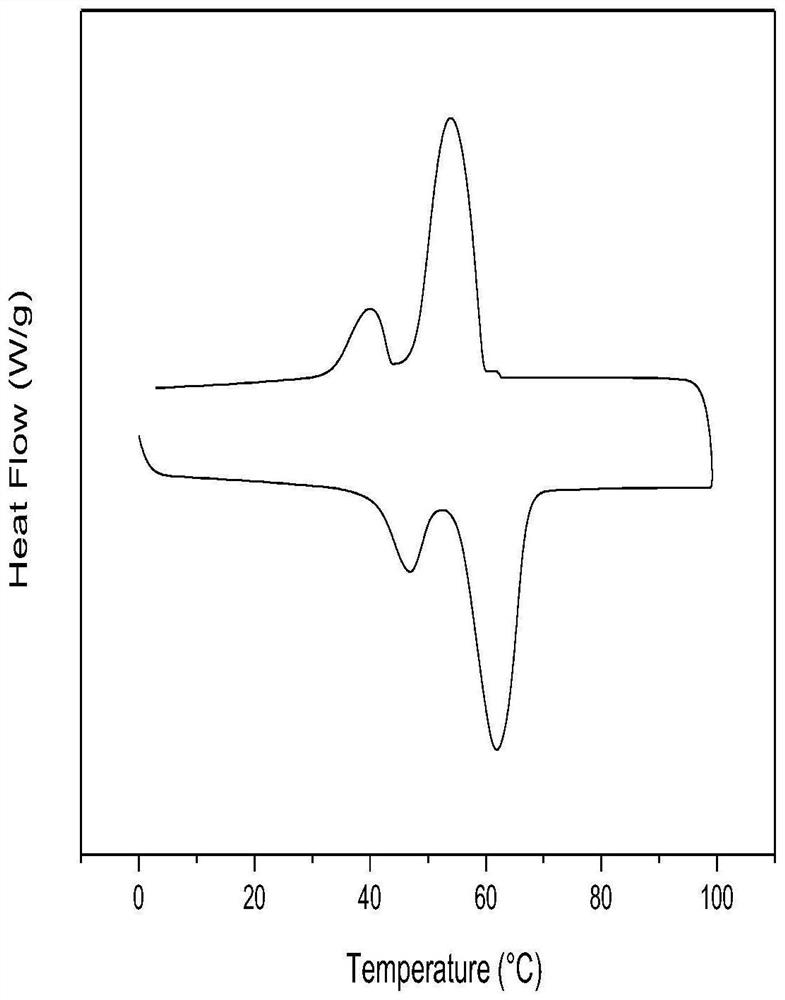

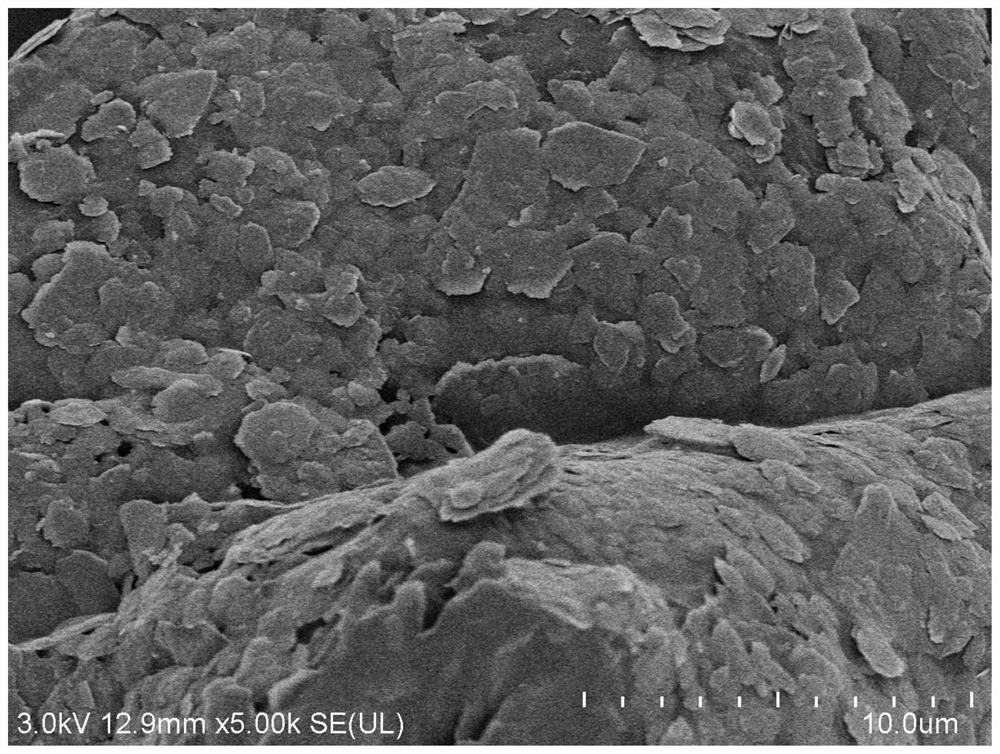

[0049] S3. Cut 10 g of paraffin into pieces with a knife, take 0.1 g of modified illite and prepare a modified illite ...

Embodiment 2

[0056] The preparation method of paraffin / silicon dioxide / modified illite powder phase change microcapsules is as follows:

[0057] S1. Use gravity separation method to separate illite to obtain purified illite (mainly: add 3 g of illite to 60 mL of distilled water, continue magnetic stirring after ultrasonication to make it evenly dispersed, use plastic wrap for the beaker After sealing, let stand, discard the supernatant, transfer the intermediate suspension and bottom impurities to a desktop centrifuge for solid-liquid separation. After drying, the purified illite is obtained);

[0058] S2. Take 0.1 g of sodium carbonate as the sodium modification agent, and after obtaining sodium-based modified illite, add 0.5 g of cetyltrimethylammonium bromide, continue stirring at 80 °C for 7 hours, and finally dry at 100 °C, That is to obtain modified illite;

[0059] S3. Cut 10 g of paraffin wax into pieces with a knife, take 0.2 g of modified illite and prepare a modified illite so...

Embodiment 3

[0065] Prepare a new type of phase change silicone rubber foam material according to the following proportions

[0066] Liquid silicone rubber (107 silicone rubber) A: 10g, hydrogen-containing silicone oil: 2g, methyl silicone oil: 0.2g, liquid silicone rubber B: 2.7, phase change microcapsule: 5g

[0067] Implementation process: First, mix liquid silicone rubber, hydrogen-containing silicone oil and methyl silicone oil with a mass of 10g, 2g, and 0.2g as component A, add 5g of microcapsule phase change material solid powder to component A, and add 2.7g of liquid silicone rubber containing 0.3% Pt catalyst was named as component B, then component A was transferred to component B, and stirred rapidly with an electric stirrer for about 60s, and the above mixture was immediately put into the temperature of 60 ℃. A new type of composite phase change silicone rubber foam material was obtained after curing for 40 min in a vacuum oven.

[0068] Product properties of the obtained com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com